A kind of lithium-toned manganese-containing colored glass and firing method thereof

A technology for colored glass and toning, which is applied in the field of inorganic non-metallic materials and can solve the problems such as difficulty in controlling the color of manganese-containing glass and chromatic aberration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

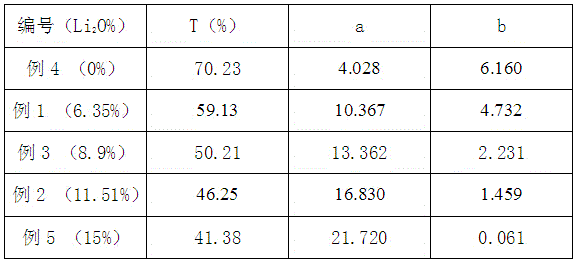

Embodiment 1

[0017] A lithium-toned manganese-containing colored glass, which is fired from silicon oxide, calcium oxide, manganese oxide, sodium nitrate and toner lithium oxide. The contents of each component of the colored glass are 88% silicon oxide, 0% calcium oxide, 0.15% manganese oxide, 5.5% sodium nitrate and 6.35% lithium oxide.

[0018] The firing method of the above-mentioned manganese-containing colored glass toned by lithium comprises the following steps:

[0019] 1) Select suitable raw materials for batching, and ensure that the content of each component in the selected raw materials meets the ratio of the above requirements;

[0020] 2) The prepared mixture is fully melted at 1445°C and then molded, and then annealed at 600°C to obtain the product.

[0021] Step 2) When the mixture is melting, first raise the temperature uniformly to 200°C within 60-70 minutes, then raise the temperature from 200°C to 1445°C within 170-180 minutes, and keep the temperature at 1445°C until t...

Embodiment 2

[0023] A lithium-toned manganese-containing colored glass is fired from silicon oxide, calcium oxide, manganese oxide, sodium nitrate and toner lithium oxide. The contents of each component of the colored glass are 50% silicon oxide, 38% calcium oxide, 0.15% manganese oxide, 0.34% sodium nitrate and 11.51% lithium oxide.

[0024] The firing method of the above-mentioned manganese-containing colored glass toned by lithium comprises the following steps:

[0025] 1) Select suitable raw materials for batching, and ensure that the content of each component in the selected raw materials meets the ratio of the above requirements;

[0026] 2) The prepared mixture is fully melted at 1445°C and then molded, and then annealed at 600°C to obtain the product.

[0027] Step 2) When the mixture is melting, first raise the temperature uniformly to 200°C within 60-70 minutes, then raise the temperature from 200°C to 1445°C within 170-180 minutes, and keep the temperature at 1445°C until the m...

Embodiment 3

[0029] A lithium-toned manganese-containing colored glass, which is fired from silicon oxide, calcium oxide, manganese oxide, sodium nitrate and toner lithium oxide. The contents of each component of the colored glass are 69% silicon oxide, 19% calcium oxide, 0.15% manganese oxide, 2.95% sodium nitrate and 8.9% lithium oxide.

[0030] The firing method of the above-mentioned manganese-containing colored glass toned by lithium comprises the following steps:

[0031] 1) Select suitable raw materials for batching, and ensure that the content of each component in the selected raw materials meets the ratio of the above requirements;

[0032] 2) The prepared mixture is fully melted at 1445°C and then molded, and then annealed at 600°C to obtain the product.

[0033] Step 2) When the mixture is melting, first raise the temperature uniformly to 200°C within 60-70 minutes, then raise the temperature from 200°C to 1445°C within 170-180 minutes, and keep the temperature at 1445°C until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com