Epoxypropane production method

A technology of propylene oxide and its production method, which is applied in the field of propylene oxide production and can solve the problems of low propylene oxide selectivity and poor catalyst stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Under 100 ° C and 0.3MPa, the Moorbi of the isopenenezen and the air is 1: 5 conditions, the oxidation reaction of the isopenenezen and the air is performed to obtain a hydrogen peroxide oxide with a weight concentration of 22%.

[0022] NA 2 CO 3 Wash the hydrogen peroxide oxide liquid with a weight of 5%of the water solution, where the volume ratio of oxide and alkali solution is 4: 1, which removes the acidic substances in it.Then use the deodorized oxidation liquid to remove the NA remaining due to alkali washing + Among them, the volume ratio of oxidation and ionic water is 4: 1.According to the needs of the epoxy reaction, the vacuum reinforcement is performed, and the concentration temperature is 100 ° C to obtain a hydrogen peroxide concentration of 40%of the oxidation solution.It was removed.After treatment, the weight content of the acidic substances in hydrogen peroxide isopenhexide is 50 ppm, H 2 O weight content is 100ppm, NA + The weight content is 50 ppm.

[...

Embodiment 2

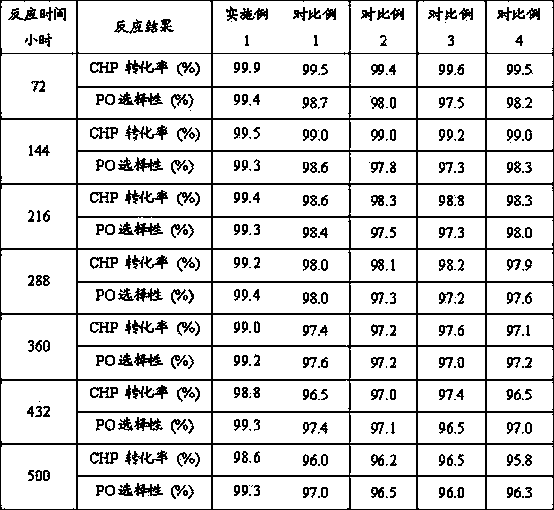

[0044] Same as [Example 1], but the weight content of acidic substances is 50 ppm, H 2 O weight content is 100ppm, NA + The weight content is 100ppm.The reaction result is shown in Table 2.

Embodiment 3

[0046] Same as [Example 1], but the weight content of acidic substances is 100 ppm, H 2 O weight content is 50 ppm, NA + The weight content is 50 ppm.The reaction result is shown in Table 2.

[0047] Table 2

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com