Technology for separating and purifying bismuth from lead-bismuth alloy

A lead-bismuth alloy and process technology, applied in the field of separation and purification of bismuth smelting, can solve the problems of easy pollution of the environment, increase of total cost, environmental pollution, etc., and achieve the effect of simple and easy process, less equipment and investment, and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

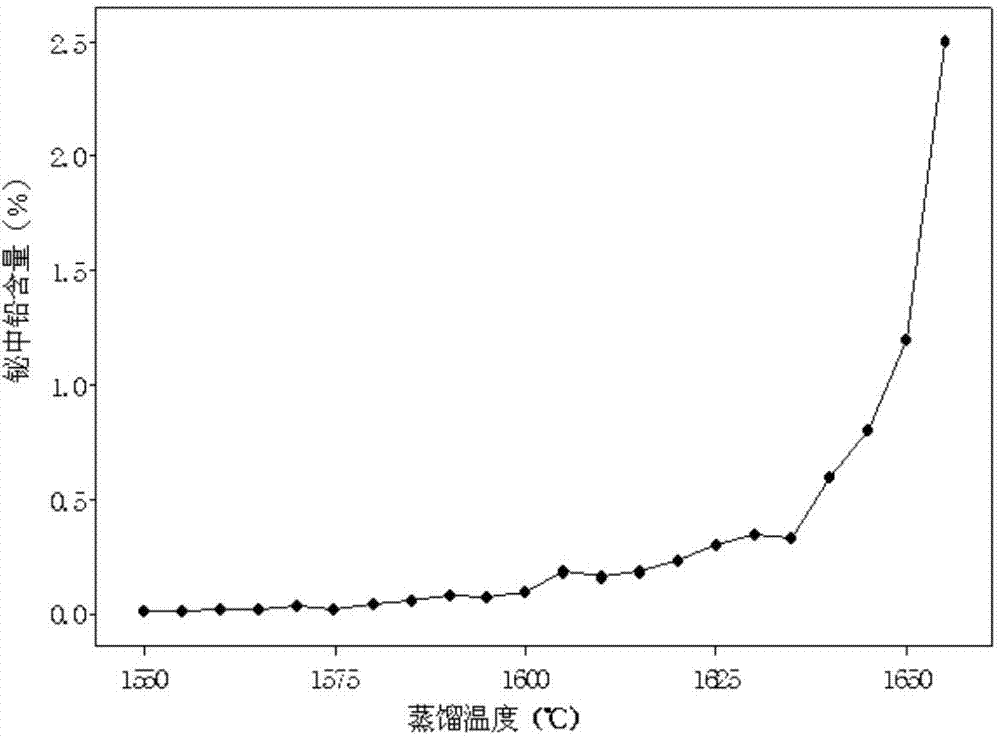

[0020] The lead-bismuth alloy used comes from a smelter in Jiangxi, wherein the content of Fe, Cu, As and Cd is below 0.3wt%, the content of Sb is below 0.5wt%, and the content of Ag is within 2wt%. Adopt atomic absorption spectrometry to detect; Detection instrument: atomic absorption spectrophotometer (containing hydride generator), AA320N.

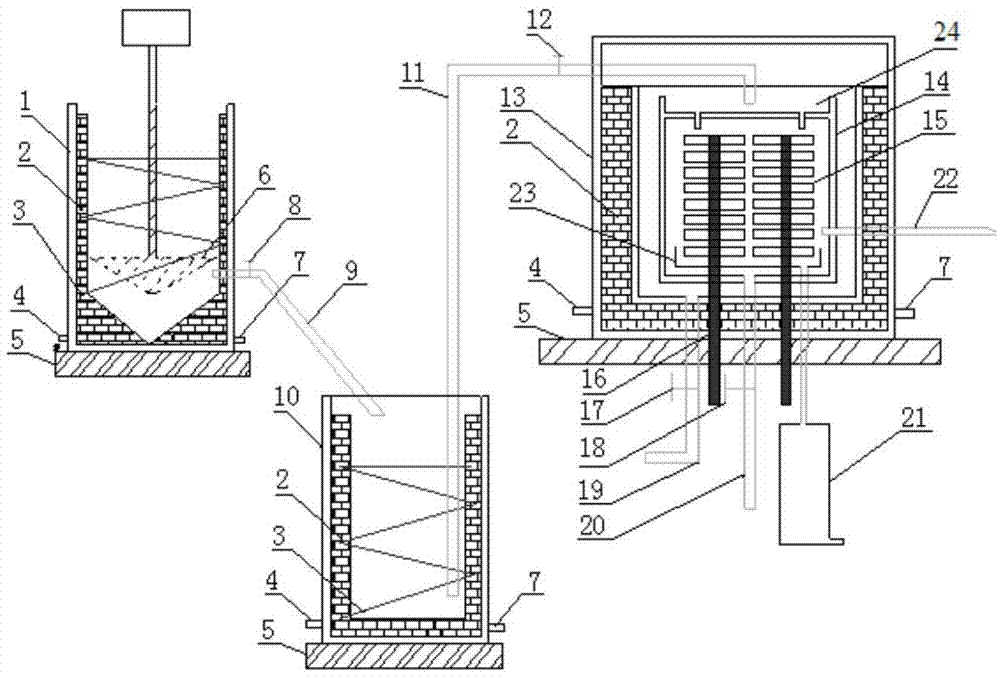

[0021] Refer to attached figure 2 The vacuum distillation separation device system carries out the distillation and separation of lead-bismuth alloy to purify bismuth. The vacuum distillation furnace system includes a melting furnace, a siphon tank and a vacuum distillation furnace. The vacuum distillation furnace includes a furnace body and a liner; the lower part of the melting furnace is provided with a discharge pipe, and the other end of the discharge pipe extends into the siphon tank. There is a siphon tube between the vacuum distillation furnace and the vacuum distillation furnace. One end of the siphon tube extends into the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com