Direct-connection integrated screw machine-driven asynchronous motor

An asynchronous motor, integrated technology, applied in the direction of machine/engine, electromechanical device, pump combination for elastic fluid rotary piston type/oscillating piston type, etc., can solve the problem of reducing the energy efficiency of the motor and the whole machine, large transmission mechanical noise, Issues such as high installation process requirements, to achieve the effect of improving assembly accuracy, reducing wearing parts, and simplifying structural processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

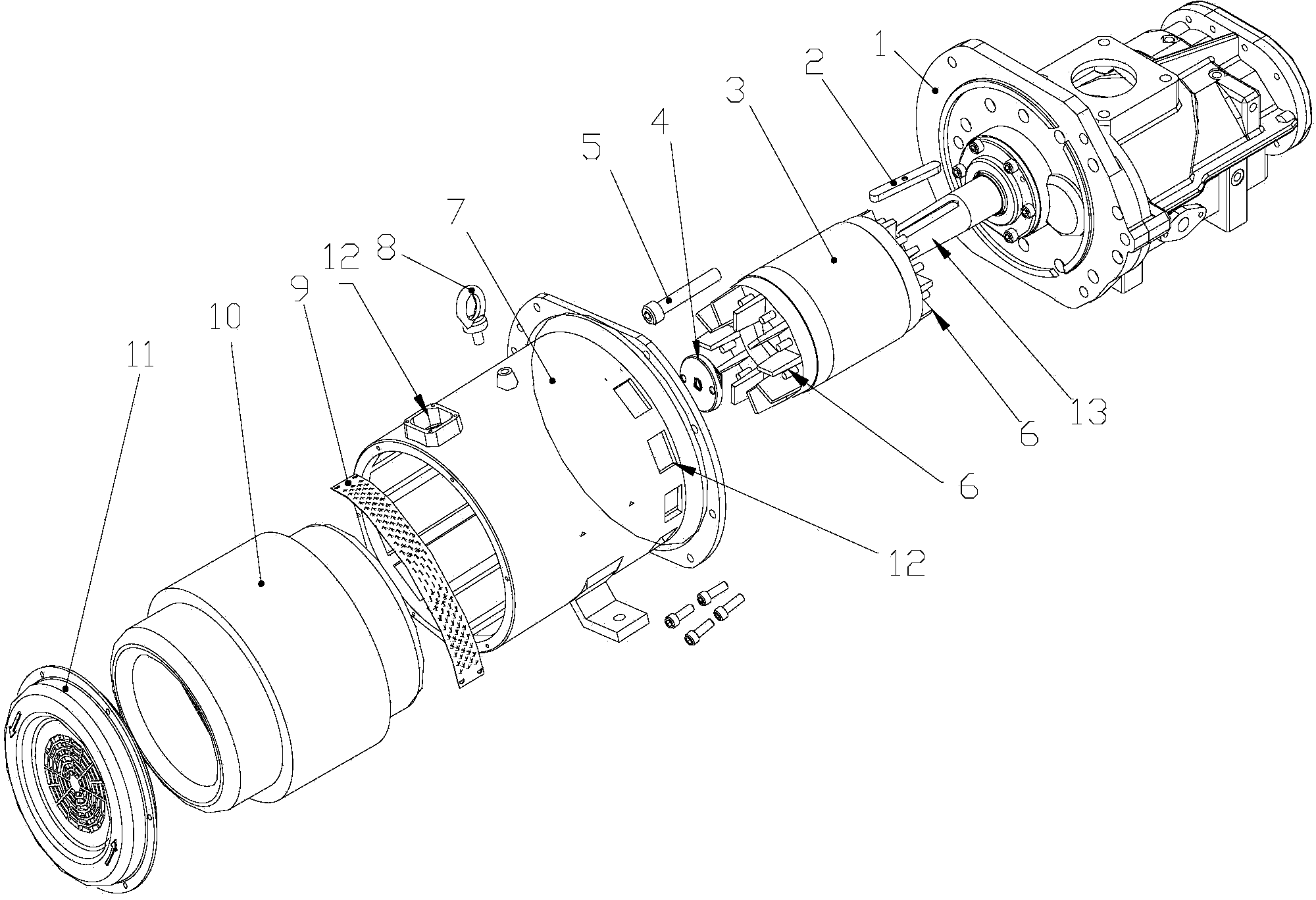

[0022] Example 1 as Figure 1~3 The asynchronous motor driven by a direct-connected integrated screw machine is shown, and the asynchronous motor includes a screw air compressor main body 1, a flat key 2, a male rotor head axon 13, a motor rotor 3, a motor barrel 7, and a stator coil 10 and the wind guide end cover 11, a flat key 2 is set on the male rotor head axon 13, the motor rotor 3 is sleeved on the male rotor head axon 13, and the flat key 2 is placed In the motor rotor 3, the stator coil 10 is socketed on the motor rotor 3, the motor cylinder 7 is socketed on the stator coil 10, and the two sides of the motor cylinder 7 are connected to the screw air compressor host 1 respectively. It is connected with the air guide end cover 11 through a flange, and a pressing device is provided between the male rotor head axon 13 and the motor rotor 3, and the pressing device can make the male rotor head axon and the motor rotor 3 interact with each other. The positioning is fixed, ...

Embodiment 2

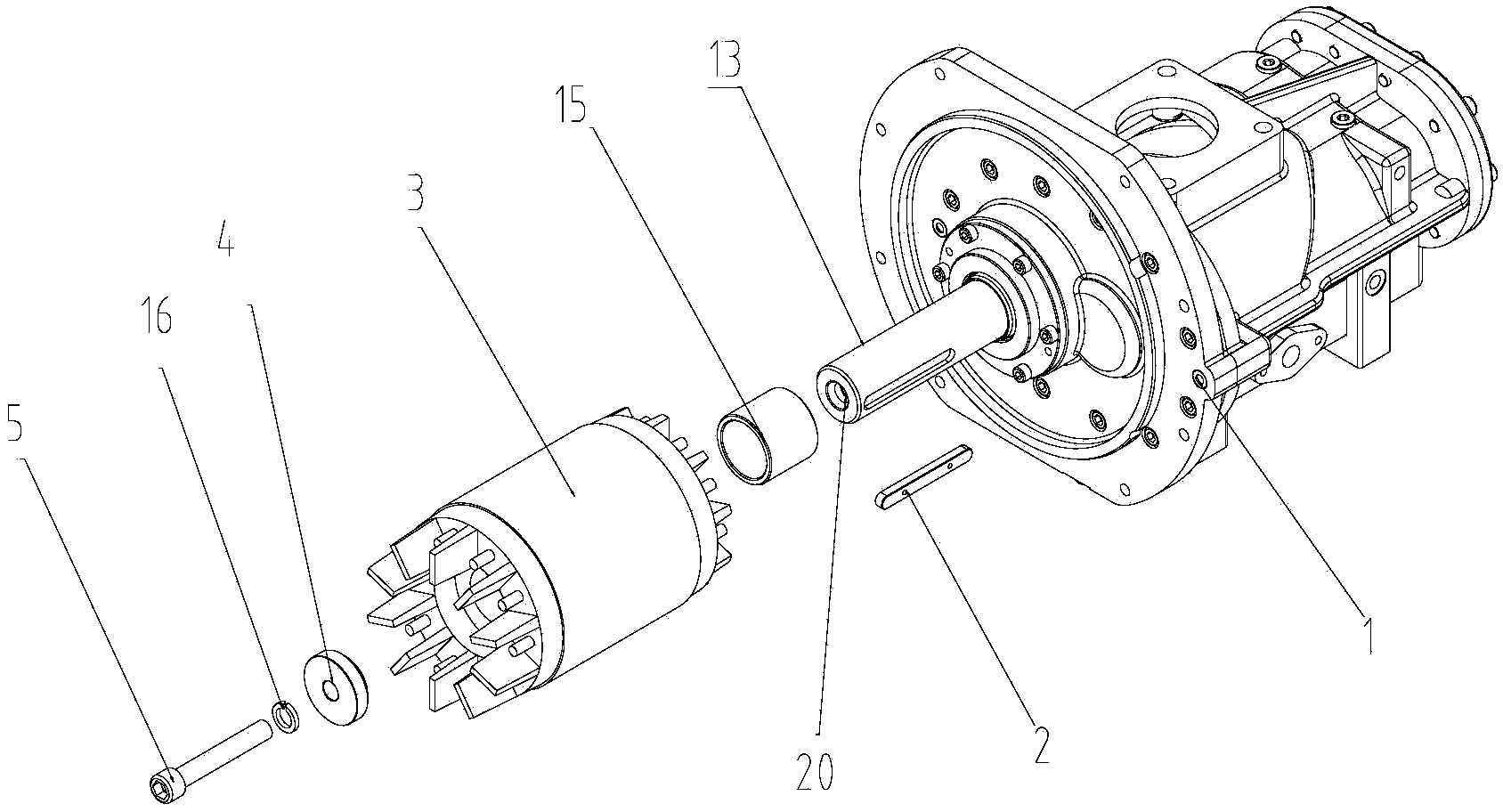

[0023] Example 2 as Figure 4~5 The asynchronous motor driven by a direct-connected integrated screw machine is shown, and the asynchronous motor includes a screw air compressor main body 1, a flat key 2, a male rotor head axon 13, a motor rotor 3, a motor barrel 7, and a stator coil 10 and the wind guide end cover 11, a flat key 2 is set on the male rotor head axon 13, the motor rotor 3 is sleeved on the male rotor head axon 13, and the flat key 2 is placed In the motor rotor 3, the stator coil 10 is socketed on the motor rotor 3, the motor cylinder 7 is socketed on the stator coil 10, and the two sides of the motor cylinder 7 are connected to the screw air compressor host 1 respectively. It is connected with the air guide end cover 11 through a flange, and a pressing device is provided between the male rotor head axon 13 and the motor rotor 3, and the pressing device can make the male rotor head axon and the motor rotor 3 interact with each other. The positioning is fixed, ...

Embodiment 3

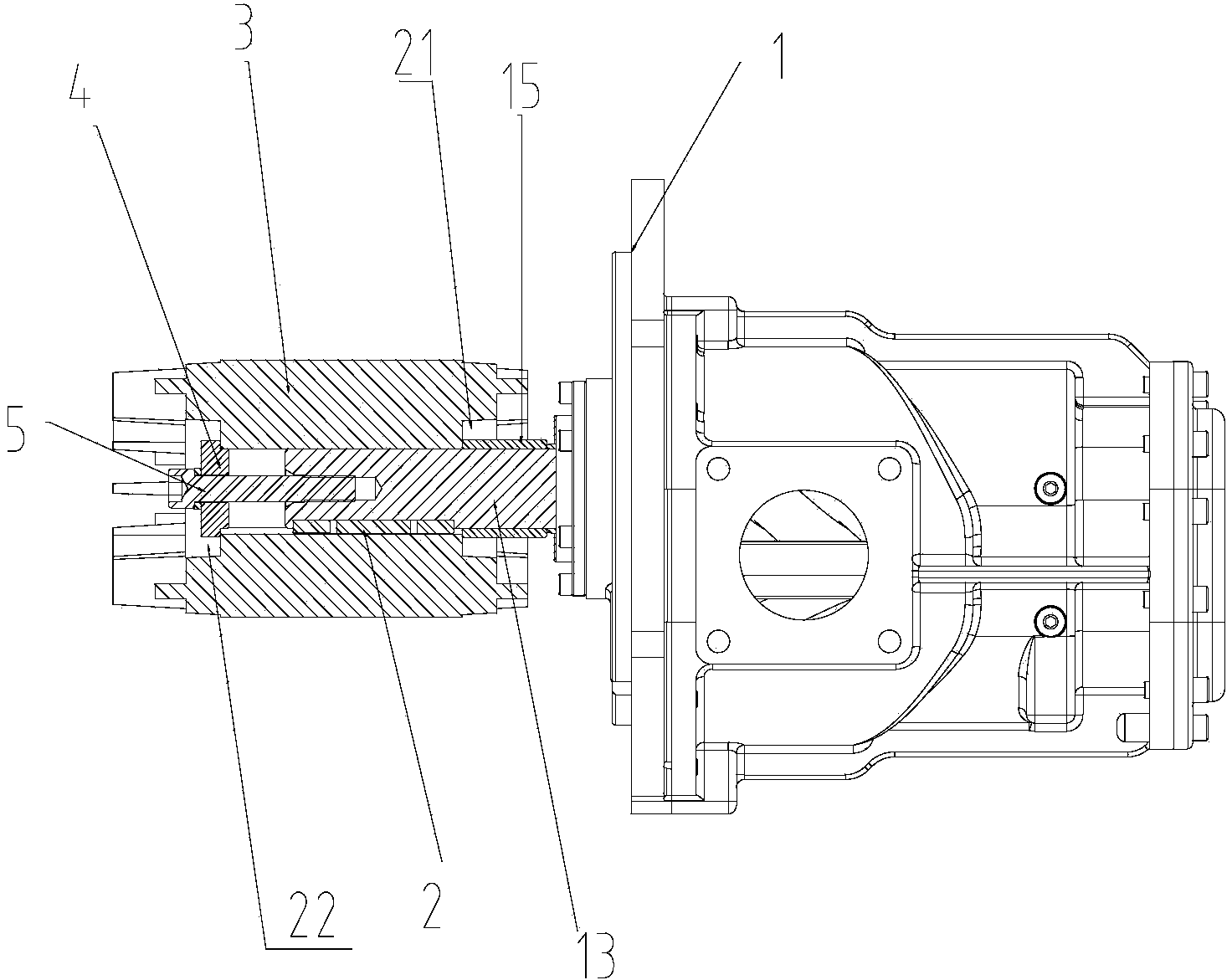

[0024] Example 3 as Figure 6~7The asynchronous motor driven by a direct-connected integrated screw machine is shown, and the asynchronous motor includes a screw air compressor main body 1, a flat key 2, a male rotor head axon 13, a motor rotor 3, a motor barrel 7, and a stator coil 10 and the wind guide end cover 11, a flat key 2 is set on the male rotor head axon 13, the motor rotor 3 is sleeved on the male rotor head axon 13, and the flat key 2 is placed In the motor rotor 3, the stator coil 10 is socketed on the motor rotor 3, the motor cylinder 7 is socketed on the stator coil 10, and the two sides of the motor cylinder 7 are connected to the screw air compressor host 1 respectively. It is connected with the air guide end cover 11 through a flange, and a pressing device is provided between the male rotor head axon 13 and the motor rotor 3, and the pressing device can make the male rotor head axon and the motor rotor 3 interact with each other. The positioning is fixed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com