Online sizing and weighing system for multi-flow multi-sizing continuous casting slab

A continuous casting slab and casting slab technology, which is applied in the field of multi-flow and multi-length continuous casting slab online fixed-length weighing system, can solve the problems of complex hanging beam equipment, lower casting slab yield, and inconvenient maintenance, and achieve system adaptation Good performance, improved adaptability and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

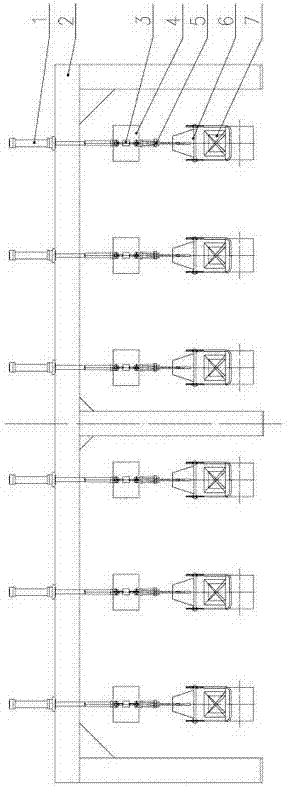

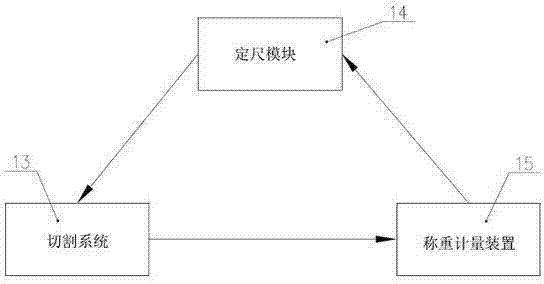

[0027] Such as figure 1 , figure 2 As shown, it is a schematic diagram of the structure of a six-machine six-strand billet continuous casting machine. Ruler weighing system, the system is made up of slab lifting mechanism, slab weighing mechanism, slab conveying mechanism, slab sizing module 14 and system closed-loop control module.

[0028]The slab lifting mechanism is driven by a hydraulic cylinder, including a lifting hydraulic cylinder 1 and three sets of portal frames 2. The portal frames 2 are fixed on both sides of the roller table. A column is used to ensure sufficient rigidity to carry out multi-strand slab weighing at the same time. The distance between the last two groups of frames along the direction of billet discharge is 4m, and the distance between the first group and the third group of frames along the direction of billet discharge is 8m. A load cell and 3 hydraulic cylinders ensure synchronous lifting of all hydraulic cylinders for each flow during the lif...

Embodiment approach 2

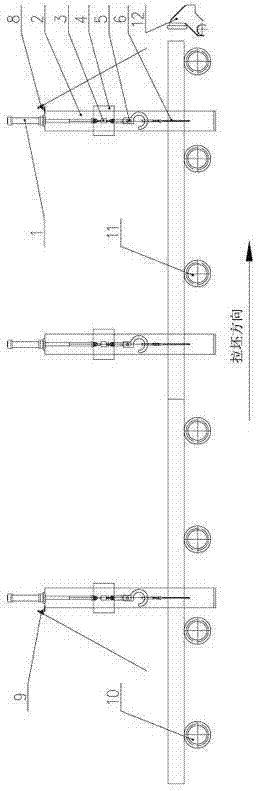

[0035] Four-machine four-strand bloom continuous casting machine, the cross-section of the billet is 350×450mm and 400×450mm respectively, the length of the length is 4m and 6m respectively, and the multi-strand multi-length continuous casting billet online scale weighing system is adopted, the system It consists of a sizing module, a slab lifting mechanism, a slab weighing mechanism, a roller conveying mechanism and a closed-loop control module.

[0036] The billet lifting mechanism is driven by a hydraulic cylinder, including a lifting hydraulic cylinder 1 and two sets of gate frames 2. The longitudinal distance between the two sets of frames 2 is 3m. The gate frames 2 are fixed on both sides of the roller table. Each set of gate frames A column is set at the central position of 2 (between the second strand and the third strand) to ensure sufficient rigidity to carry out multi-strand slab weighing at the same time. The weighing hydraulic cylinder 1 is fixed on the portal fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com