A kind of environment-friendly matte medical PVC granular material and preparation method thereof

A pellet and environmental protection technology, applied in the field of environmentally friendly matte medical PVC pellets and its preparation, can solve problems such as glare, inability to meet the requirements of high-quality medical devices, glare, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

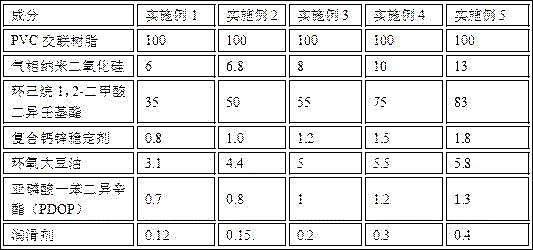

Examples

Embodiment 1

[0039] An environmentally friendly matte medical PVC pellet preparation method, the specific preparation steps are:

[0040] ①. Vibrate the PVC cross-linked resin and weigh it;

[0041] ②. Add the plasticizer, composite calcium zinc stabilizer, auxiliary stabilizer, chelating agent, and lubricant to the PVC cross-linked resin for mixing and stirring, and the stirring speed is 1450 rpm;

[0042] ③. Heat and stir to 50℃, add fumed nano silica;

[0043] ④ Stir the above mixture at a uniform speed to 65°C and send it to a low-speed mixer for cooling;

[0044] ⑤. Stir the above mixture at a stirring speed of 200 rpm;

[0045] ⑥. When the temperature of the above mixture drops to 26℃, add it to the twin-screw extrusion granulator;

[0046] ⑦. Set the barrel temperature to 135℃~180℃, and the die temperature to 155℃~165℃;

[0047] ⑧, cut into pellets.

Embodiment 2

[0049] An environmentally friendly matte medical PVC pellet preparation method, the specific preparation steps are:

[0050] ①. Vibrate the PVC cross-linked resin and weigh it;

[0051] ②. Add the plasticizer, composite calcium zinc stabilizer, auxiliary stabilizer, chelating agent, and lubricant to the PVC cross-linked resin for mixing and stirring, and the stirring speed is 1450 rpm;

[0052] ③, heat and stir to 51 ℃, add fumed nano silica;

[0053] ④. Stir the above mixture at a uniform speed to 66°C and send it to a low-speed mixer for cooling;

[0054] ⑤. Stir the above mixture at a stirring speed of 200 rpm;

[0055] ⑥. After the temperature of the above mixture drops to 27°C, add it to the twin-screw extrusion granulator;

[0056] ⑦. Set the barrel temperature to 135℃~180℃, and the die temperature to 155℃~165℃;

[0057] ⑧, cut into pellets.

Embodiment 3

[0059] An environmentally friendly matte medical PVC pellet preparation method, the specific preparation steps are:

[0060] ①. Vibrate the PVC cross-linked resin and weigh it;

[0061] ②. Add the plasticizer, composite calcium zinc stabilizer, auxiliary stabilizer, chelating agent, and lubricant to the PVC cross-linked resin for mixing and stirring, and the stirring speed is 1450 rpm;

[0062] ③. Heat and stir to 52℃, add fumed nano silica;

[0063] ④. Stir the above mixture at a uniform speed to 67°C and send it to a low-speed mixer for cooling;

[0064] ⑤. Stir the above mixture at a stirring speed of 200 rpm;

[0065] ⑥. After the temperature of the above mixture drops to 27°C, add it to the twin-screw extrusion granulator;

[0066] ⑦. Set the barrel temperature to 135℃~180℃, and the die temperature to 155℃~165℃;

[0067] ⑧, cut into pellets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com