A method for mitigating slagging and fouling when burning polyalkali metal fuels

An alkali metal and fuel technology, applied in the combustion method, combustion equipment, fuel supply and other directions, can solve the problems of shortening the life of the pipe, falling off the ash and slag layer, and immaturity, so as to reduce the slagging and fouling, and improve the serious fouling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

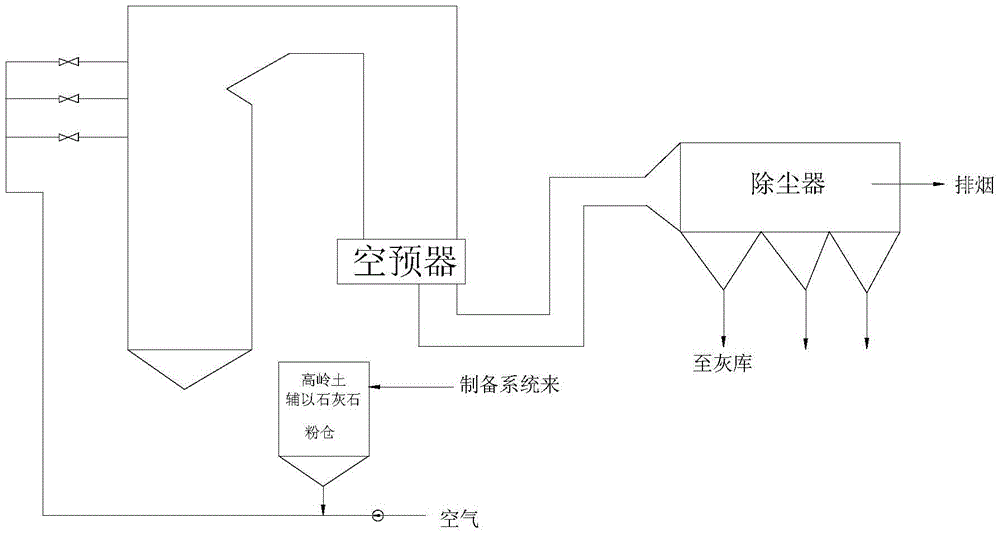

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] see figure 1 , a method for reducing slagging and contamination when burning polyalkali metal fuels, comprising the following steps: when burning polyalkali metal fuels, sending mixed powder mixed with kaolin with a small amount of limestone powder into kaolin through a preparation system The powder bin, and then the mixed powder is sent into the pneumatic injection device by pneumatic conveying, and then the mixed powder is injected into the high temperature zone in the furnace through the pneumatic injection device.

[0028] When burning polyalkali metal fuel, the content of kaolin powder added is based on the Na in the polyalkali metal fuel 2 The O equivalent is determined, where Na in the multi-alkali metal fuel 2 The O equivalent is given by the following formula:

[0029] (Na 2 O) d =(0.659K 2 O+Na 2 O)×A d ÷100(1)

[0030] Where: (Na 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com