Quantitative determination method for fiber content of viloft fiber and acrylic fiber or spandex blended textiles

A quantitative detection method and fiber content technology, which is applied in the detection field of fiber content of blended products containing viloft fiber and acrylic fiber or spandex, can solve the problems that affect the accuracy of measurement results, the efficiency of measurement work, and low detection efficiency, and achieve high accuracy performance, shorten detection time, and improve detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

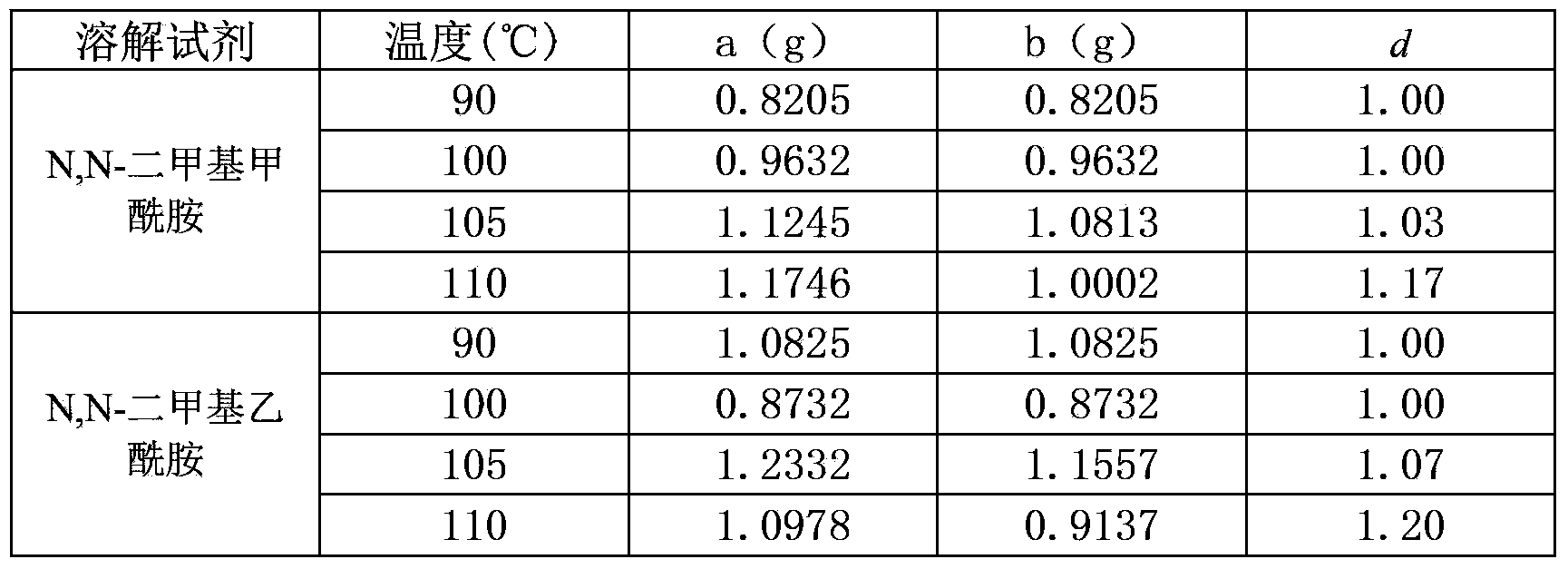

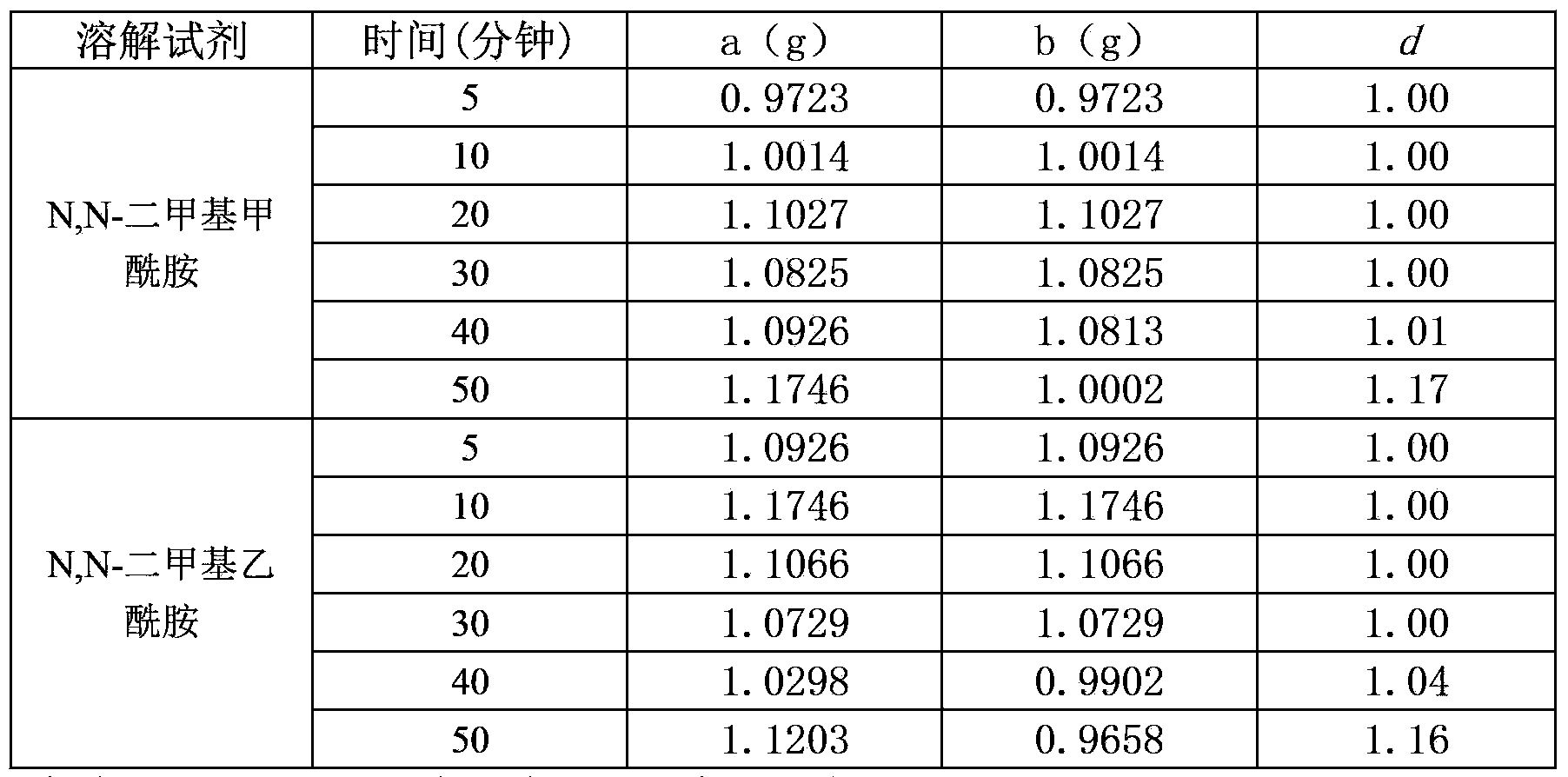

[0020] Embodiment 1 viloft fiber correction factor test

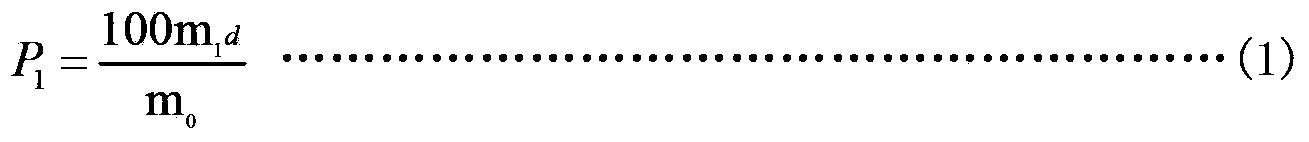

[0021] Take a certain amount of viloft fiber and place it in a constant temperature oven at 105°C for 3 hours. After it is fully dried, take it out quickly and place it in a desiccator to cool to room temperature. Weigh the viloft fiber with a balance with an accuracy of 0.1 mg According to the weight of the blended product (g): reagent (mL) = 1:100 bath ratio, the blended product is calculated by mass (g), the reagent is calculated by volume (mL), and the viloft fiber is placed at 90-110 In the N,N-dimethylformamide or N,N-dimethylacetamide solution under the condition of ℃, after continuous shaking for 5 minutes to 30 minutes, rinse the viloft fiber twice with the same temperature reagent and then clean it with water. Dry it in a constant temperature oven at 105°C, then quickly take it out and place it in a desiccator to cool to room temperature, and weigh b with a balance with an accuracy of 0.1 mg. By comparing a a...

Embodiment 2

[0027] Example 2 N, N-dimethylformamide dissolved acrylic fiber test

[0028] Take 2 parts of viloft fiber and acrylic fiber blended products whose component content is unknown, and place them in a constant temperature oven at 105°C for 3 hours. Weigh the weight of the blended product with a balance with a density of 0.1 mg, and record it as m 0 According to the sample (g): reagent (mL) = 1:100 bath ratio, the blended product is placed in the N,N-dimethylformamide solution at 100 ° C, and after continuous shaking for 5 minutes, the acrylic fiber is completely dissolved in For N,N-dimethylformamide solution, wash the insoluble fiber (viloft fiber) with water until neutral, dry it in a constant temperature oven at 105°C, then quickly take it out and cool it to room temperature in a desiccator. The balance of 0.1mg weighs m 1 . Among them, the mass of viloft fiber in the blended product is m 1 , the mass of acrylic fiber is m 0 -m 1 .

[0029] After calculation and reasoni...

Embodiment 3

[0038] Example 3 N, N-dimethylacetamide dissolved acrylic fiber test

[0039] Take 2 parts of viloft fiber and acrylic fiber blended products whose component content is unknown, and place them in a constant temperature oven at 105°C for 3 hours. Weigh the weight of the blended product with a balance with a density of 0.1 mg, and record it as m 0 According to the sample (g): reagent (mL) = 1:150 bath ratio, the blended product was placed in N,N-dimethylacetamide solution at 95°C, and after continuous shaking for 10 minutes, the acrylic fiber was completely dissolved in N , N-dimethylacetamide, wash the insoluble fiber, viloft fiber, twice with N,N-dimethylacetamide at the same temperature, then wash it with water, dry it in a constant temperature oven at 105°C, and then quickly Take it out and place it in a desiccator to cool to room temperature, and weigh m with a balance with an accuracy of 0.1 mg 1 . Among them, the mass of viloft fiber in the blended product is m 1 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com