Anti-allergic hair oiling and dyeing cream, and manufacturing method thereof

A production method and technology of hair dye cream, which are applied in hair care, pharmaceutical formulations, cosmetic preparations, etc., to achieve the effects of simple processing and production technology, low cost of raw materials, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

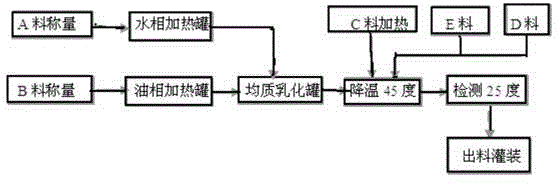

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is an anti-allergic hair dyeing paste, which contains: 6%-10% thickener, 1%-5% Ph value regulator, 2%-8% emulsifier, 1%- 5% conditioner, 0.5% to 15% antioxidant, 0.1% to 0.5% colorant and 0.1% to 0.3% fragrance, and the rest is solvent.

[0029] A preferred embodiment of the present invention is that the thickener is stearyl alcohol, the pH regulator is ammonium hydroxide, the emulsifier is glyceryl stearate and sodium lauryl sulfate, and the conditioner The agent is mineral oil, sunflower seed oil, walnut seed oil and Polygonum multiflorum extract, the antioxidant is ascorbic acid and sodium sulfite, the colorant is M-aminophenol, the fragrance is essence, and the solvent is water.

[0030] A further preferred embodiment of the present invention is that the emulsifier contains 1% to 4% glyceryl stearate and 1% to 4% sodium lauryl sulfate by weight percentage.

[0031] Further preferred embodiments of the present invention also include, in the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com