A kind of separation method of n-methylpiperazine and n-ethylpiperazine

A technology of methylpiperazine and ethylpiperazine, which is applied in the field of separation and purification of fine chemicals, can solve the problems of failure to meet the separation requirements and difficulty in meeting the separation requirements, and achieve the effect of solvent recycling and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

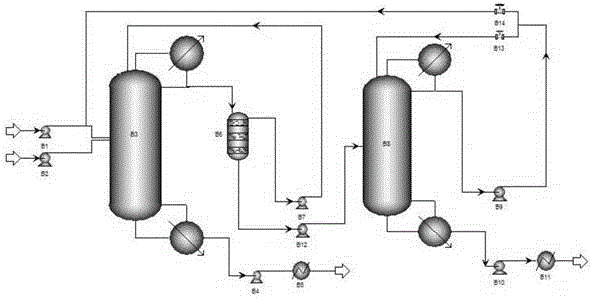

Image

Examples

Embodiment 1

[0016] Crude material N-methylpiperazine and N-ethylpiperazine are pumped into the azeotrope column B3 with the crude product feed pump B2, and the feed position is at 10 theoretical plates, and the azeotrope feed pump B1 is used to feed the azeotrope The boiling agent is injected into the azeotropic column B3, the entrainer is toluene, the feed position is 10 theoretical plates, the mass ratio of the entrainer to the crude material is 1:1, and the number of theoretical plates of the azeotropic column is not less than 30 theoretical trays, the reflux ratio is 0.1:1, the operating pressure is 0.1atm, N-ethylpiperazine is extracted from the tower kettle by the N-ethylpiperazine product pump B4, and filled after being cooled by the condenser B5. The top material of the azeotropic tower is separated by the phase separator B6, the upper entrainer is circulated back to the azeotrope tower through the entrainer circulation pump B7, and the crude N-methylpiperazine in the lower layer i...

Embodiment 2

[0018] The same operation as in Example 1, the crude feed position is the 13th theoretical plate, the entrainer is m-xylene, the feed position is the 13th theoretical plate, the quality of the entrainer and the crude The ratio is 3:1, the number of theoretical plates of the azeotropic column is 35 theoretical plates, the reflux ratio is 4:1, the operating pressure is 0.5 atm, and the feeding position of the N-methylpiperazine crude product in the lower layer of the phase separator is 12 At the theoretical plate, the theoretical plate number of the purification tower is 25 theoretical plates, the reflux ratio is 2:1, and the operating pressure is 0.5 atm. The purity of N-methylpiperazine and N-ethylpiperazine determined by gas chromatography was 99.6% and 99.3%, respectively.

Embodiment 3

[0020] The same operation as in Example 1, the crude feed position is the 15th theoretical plate, the entrainer is mesitylene, the feed position is the 15th theoretical plate, the quality of the entrainer and the crude The ratio is 1:1, the number of theoretical plates of the azeotropic column is 30 theoretical plates, the reflux ratio is 0.1:1, the operating pressure is 1 atm, and the feeding position of the N-methylpiperazine crude product in the lower layer of the phase separator is 15 theoretical plates At the tray, the number of theoretical trays in the purification tower is 30 theoretical trays, the reflux ratio is 0.1:1, and the operating pressure is 1 atm. The purity of N-methylpiperazine and N-ethylpiperazine determined by gas chromatography was 99.8% and 99.8%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com