Extraction separation method for isorhamnetin-3-O-beta-D-rutinoside in caragana sinica flower bud

A separation method, gorse technology, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of difficult scale-up production, high gel market price, small processing capacity, etc., and the method is simple Feasible, less loss, easy regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

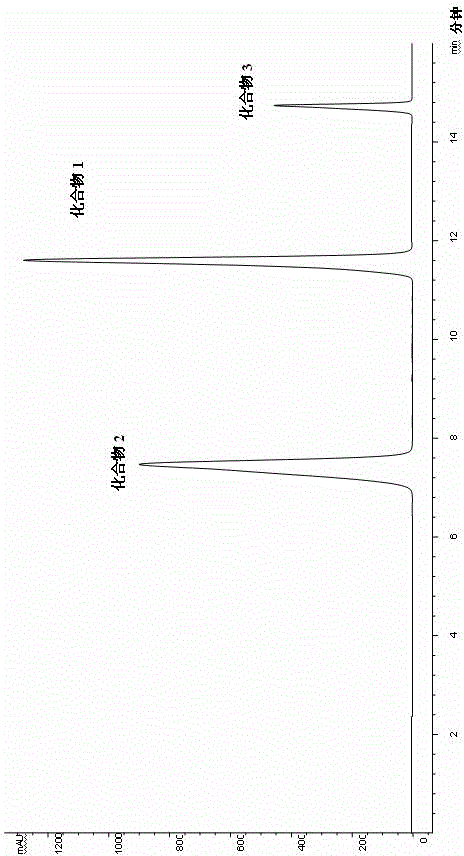

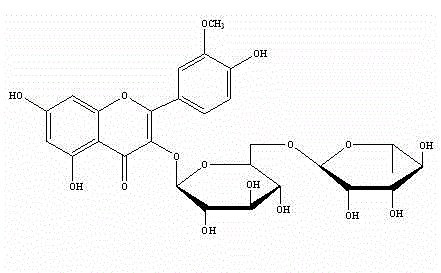

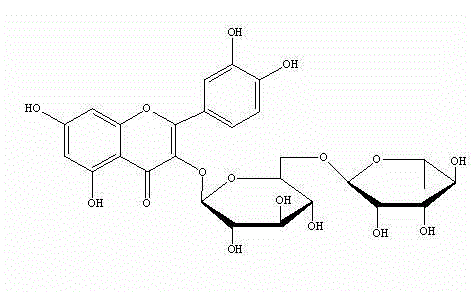

Image

Examples

Embodiment 1

[0028] Embodiment 1: Isorhamnetin-3-O- in this gorse flower bud β -The extraction and separation method of D-rutinose, the specific content is as follows:

[0029] (1) Crushing and extraction

[0030] Take 10 kg of gorse flower buds dried in the shade, crush them (the diameter of the fragments is about 1.5 mm), add 12 times the mass percentage of ethanol water solution with a concentration of 75%, reflux extraction twice, each time for 1.5 hours, and extract the extract while it is hot. , to obtain a crude sample of 1.5 kg of the extract;

[0031] (2) Extraction, separation and purification

[0032] Add 3 times the weight of the crude extract to the crude extract to dissolve in hot water at 45°C. The solution is first extracted three times with petroleum ether, and the petroleum ether extraction phase is discarded, then extracted three times with ethyl acetate, and the ethyl acetate extraction phase is discarded. , and finally extracted three times with n-butanol, the combi...

Embodiment 2

[0047] Embodiment 2: Isorhamnetin-3-O- in this gorse flower bud β -The extraction and separation method of D-rutinose, the specific content is as follows:

[0048] (1) Crushing and extraction

[0049] Take 10 kg of gorse flower buds dried in the shade, crush them (the diameter of the fragments is about 1.0 mm), add 15 times the mass percentage of ethanol water solution with a concentration of 70%, reflux extraction twice, each time for 1.0 hours, extract and concentrate while hot , to obtain a crude sample of 1.8 kg of extract;

[0050] (2) Extraction, separation and purification

[0051] Add 4 times the weight of the crude extract to the crude extract to dissolve in hot water at 40°C. The solution is first extracted twice with petroleum ether, discard the petroleum ether extract, then extract twice with ethyl acetate, and discard the ethyl acetate. The extract phase was finally extracted 3 times with n-butanol, and the n-butanol extracts were combined and concentrated to ...

Embodiment 3

[0052] Embodiment 3: Isorhamnetin-3-O- in the flower buds of this gorse β -The extraction and separation method of D-rutinose, the specific content is as follows:

[0053] (1) Crushing and extraction

[0054] Take 10 kg of shade-dried gorse flower buds, crush them (the diameter of the fragments is about 2mm), add 15 times the mass percentage of ethanol water solution with a concentration of 80%, and reflux twice for 1.2 hours each time. The extract is extracted and concentrated while it is hot. 2.1kg crude extract sample was obtained;

[0055] (2) Extraction, separation and purification

[0056] Add 5 times the weight of the crude sample to the crude extract to dissolve in hot water at 50°C. The solution is first extracted three times with petroleum ether, and the petroleum ether extraction phase is discarded, then extracted three times with ethyl acetate, and the ethyl acetate is discarded. Finally, it was extracted with n-butanol for 3 times, and the n-butanol extracts w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com