Salt-resistant and acid-resistant concentrated foaming agent as well as preparation method and application thereof

A technology of foaming agent and surfactant, applied in the field of foaming agent, can solve the problems that the foam drainage and gas recovery process cannot be effectively solved and cannot be used normally, and achieve a wide range of operating temperature, rich and delicate foam, and a wide range of application fields Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

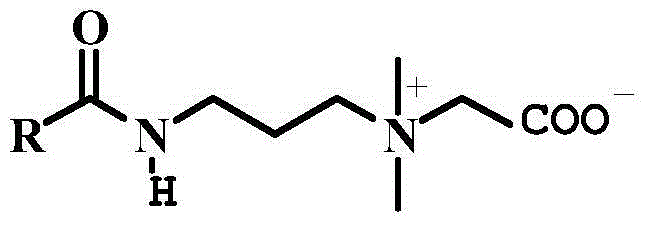

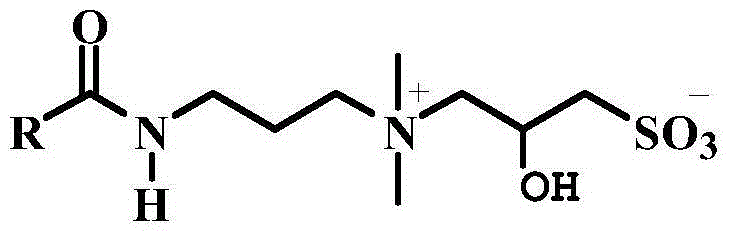

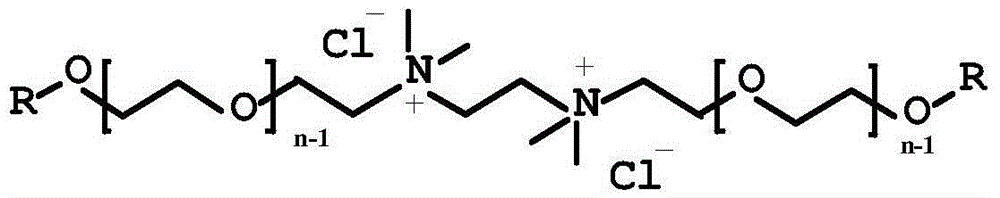

Method used

Image

Examples

Embodiment 1

[0035] Concentrated salt-resistant and acid-resistant foaming agent, including the following components by weight: 33% cocamidopropyl betaine, 5% lauryl amidopropyl hydroxy sultaine, ethylene didecanol Polyoxyethylene ether ammonium chloride 1.7%, water 60.3%.

[0036] The preparation method is as follows: under normal temperature and pressure, cocamidopropyl betaine, oleamidopropyl hydroxy sultaine and ethylene didodecanol polyoxyethylene ether ammonium chloride are added to the reaction kettle according to a certain proportion, and then Then add water and stir thoroughly for 2-3 hours until completely mixed evenly, which is the acid-resistant and salt-resistant concentrated foaming agent.

[0037] The performance of the foaming agent solution was tested. At a concentration of 0.1%, the temperature range can be stabilized at -30 to 120°C; the salt resistance can reach 1.8×104mg / L; use the stirring method (GJ-3S high-speed agitator, rotating speed 9000±200 rpm) to measure th...

Embodiment 2

[0039] Salt-resistant and acid-resistant concentrated foaming agent, including the following components by weight: 38.6% dodecylamide hydroxypropyl sulfobetaine, 6.2% dodecylbishydroxyethylmethyl ammonium chloride, Water 55.2%.

[0040] Its preparation method is identical with embodiment 1.

[0041] The performance of the foaming agent solution was tested. At a concentration of 0.1%, the temperature range can be stabilized at -30 to 120°C; the salt resistance can reach 1.8×104mg / L; use the stirring method (GJ-3S high-speed stirrer, rotating speed 9000±200 rev / min) to measure the foaming performance and foam stabilizing performance of the foaming agent, and the foaming foam quality is 77.1%, and the foam half-life is above 355min , the drainage half-life is 9.1min; the oil-water interfacial tension is 0.173mN / m.

Embodiment 3

[0043] Salt-resistant and acid-resistant concentrated foaming agent, including the following component ratios by weight: oleic acid amidopropyl betaine 28%, cetyl amidopropyl hydroxy sultaine 11%, dodecyl dihydroxy sulfobetaine Ethyl methyl ammonium chloride 2.2%, water 58.8%.

[0044] Its preparation method is identical with embodiment 1.

[0045] The performance of the foaming agent solution was tested. At a concentration of 0.1%, the temperature range can be stabilized at -30 to 120°C; the salt resistance can reach 1.8×104mg / L; use the stirring method (GJ-3S high-speed agitator, rotating speed 9000 ± 200 rpm) to measure the foaming performance and foam stabilizing performance of the foaming agent, and the foaming foam quality is 77.1%, and the foam half-life is above 352min , the drainage half-life is 9.3min; the oil-water interfacial tension is 0.175mN / m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com