Center rotary joint of earth pressure balance shield machine

A center swivel joint and earth pressure balance technology, which is applied in earth square drilling, mining equipment, tunnels, etc., can solve problems such as easy mud cake formation, and achieve the effect of solving central mud cake formation, high precision and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

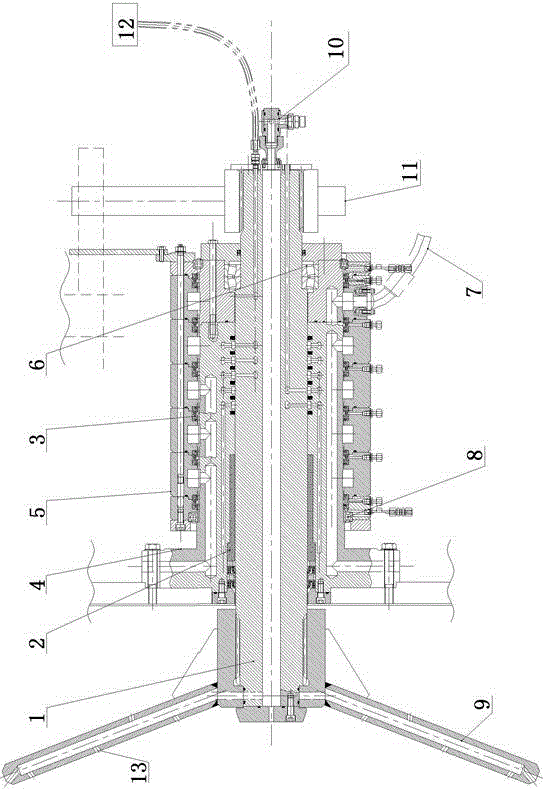

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

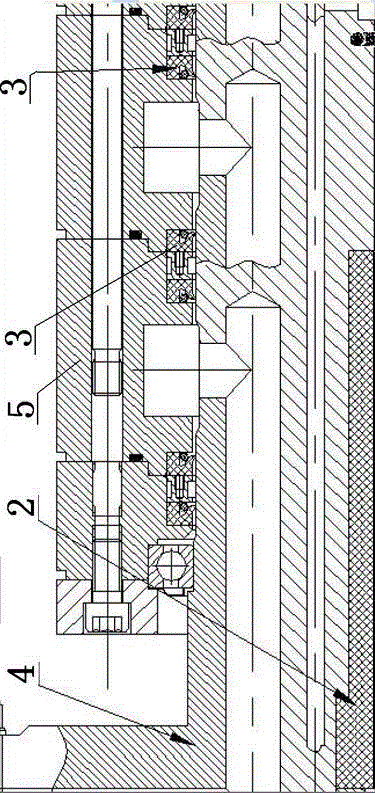

[0021] Such as figure 1 , figure 2 As shown, a central rotary joint of an earth pressure balance shield machine includes a central stator 1, and the central stator 1 and the rotor 4 are connected through bearings; the central stator 1 is connected with the passive stirring rod 9 and the block 11 through splines; 1 The tail is provided with a water spray joint device 10, the rotor 4 is connected to the surrounding stator 5 through bearings, and the rotor 4 is directly connected to the cutter head flange which is fixedly connected to the cutter head;

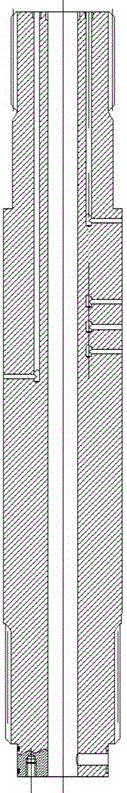

[0022] Such as figure 1 , image 3 As shown, the bearing used to connect the central stator 1 and the rotor 4 includes a sliding bearing 2 and a spherical roller bearing 6;

[0023] The passive stirring rod 9 is provided with a spout 13;

[0024] The end of the central stator 1 is directly connected to the hydraulic pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com