Gapless Metal Oxide Surge Arrester

An oxide, no-gap technology, applied in the direction of overvoltage protection resistors, varistors, etc., can solve the problems of excessive axial length of the core body, low discharge voltage capability, and small capacity of the resistance sheet group, etc., to achieve improved Effects of shock resistance, reduction of leakage current, and improvement of energy absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

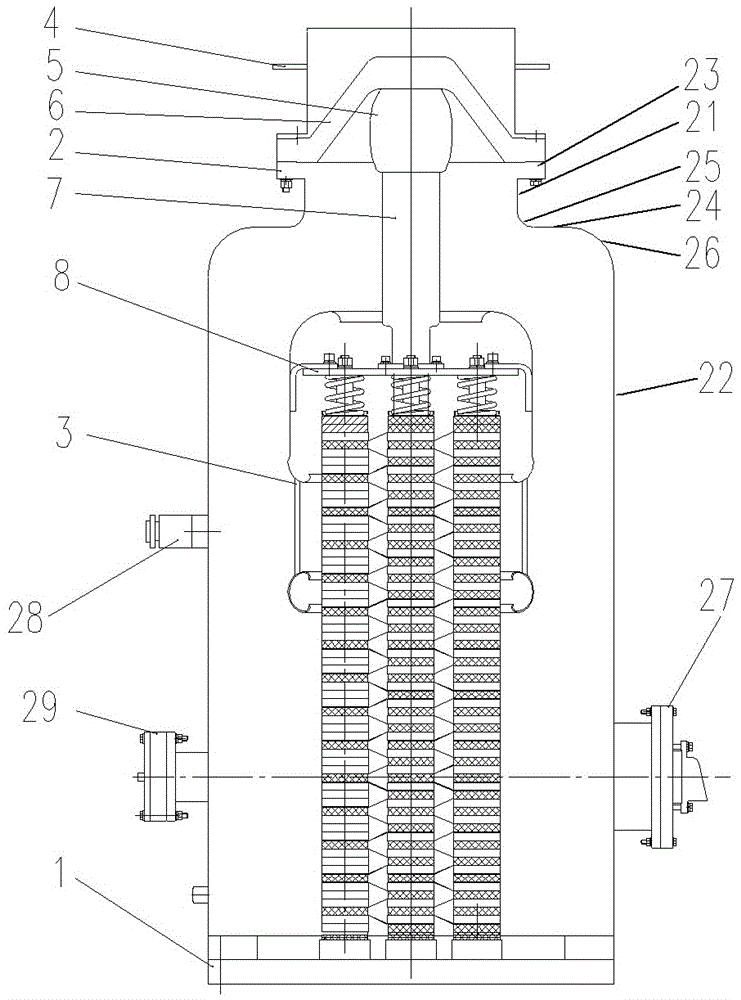

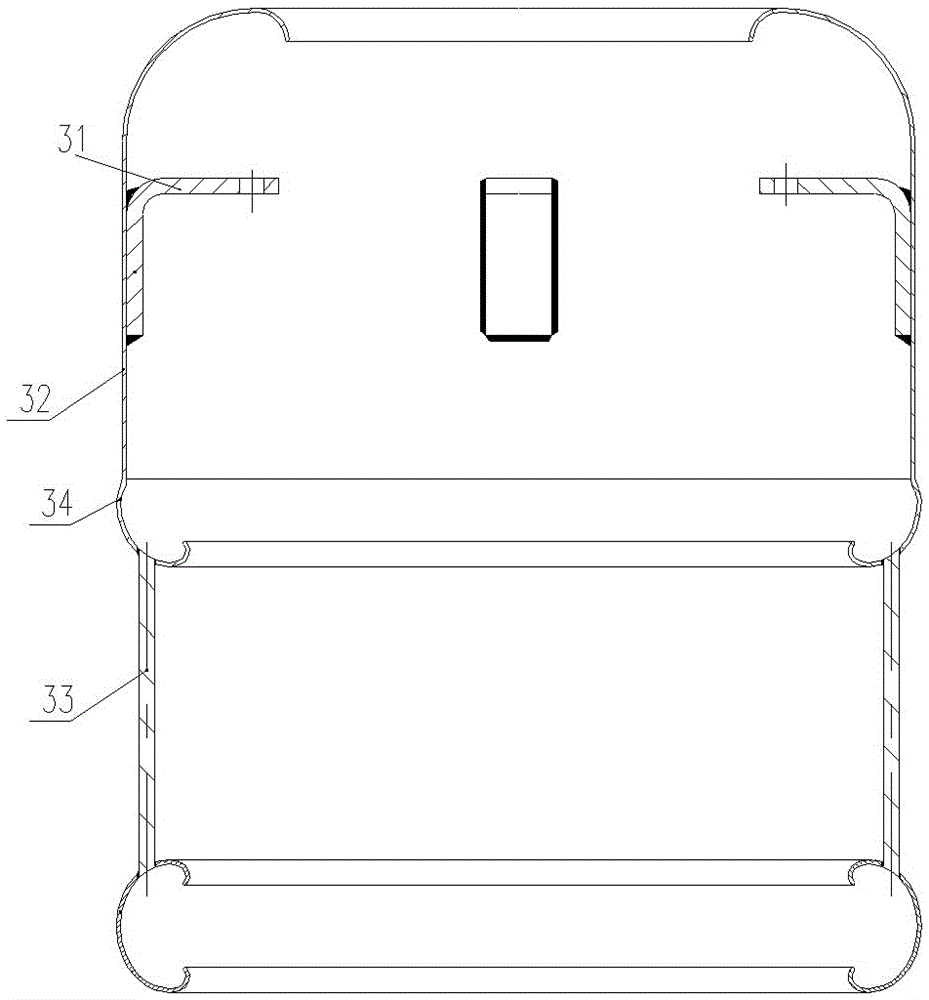

[0022] Embodiment 1 of the present invention, as Figure 1-8 As shown: the gapless metal oxide arrester includes a base 1, a cylinder 2 fixedly assembled on the base 1, a core fixed in the cylinder 2, a pressure equalizing cover 3 fixedly sleeved on the upper part of the core, and a fixed sleeve The protective cover 4 provided on the upper end of the cylinder body 2, an insulator is provided at the opening of the upper end of the cylinder body 2, and the insulator is a basin-type insulator 6, and an electrical connector 5 is fixedly mounted on the basin-type insulator 6, and the lower end of the electrical connector 5 is fixed Conductive rod 7 is arranged. The electrical connector 5, the conductive rod 7 and the core are electrically connected in sequence. The lower end of the conductive rod 7 is inserted into the pressure equalizing cover 3 .

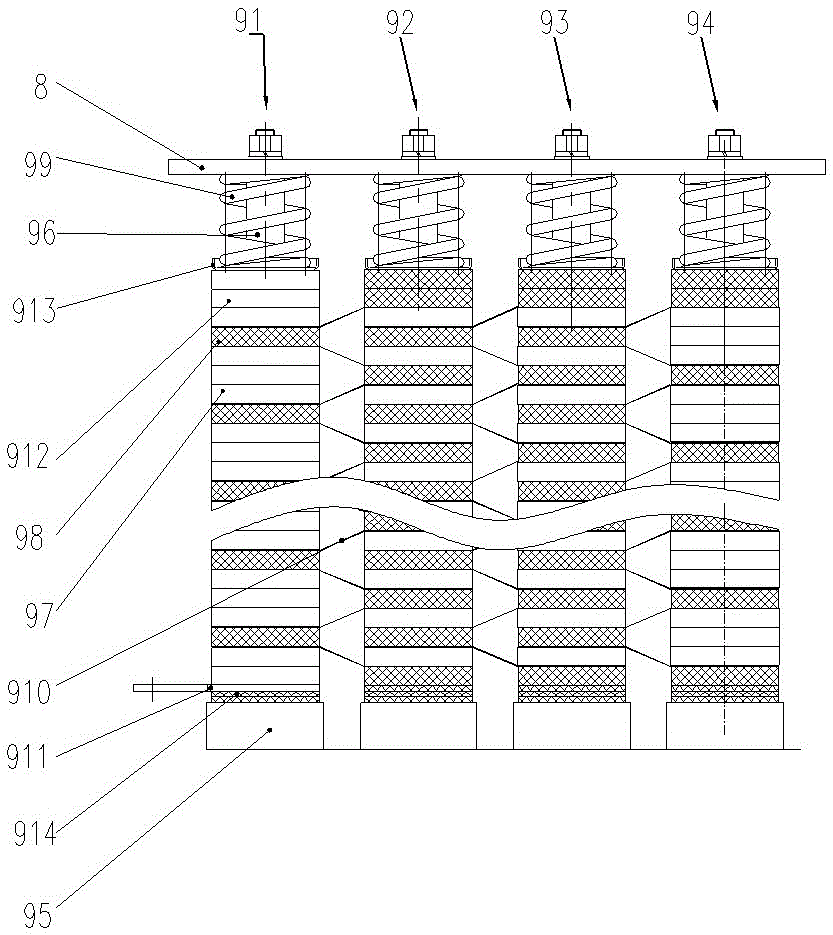

[0023] The core body includes an upper platen 8 and a cylinder located below the upper platen 8. The number of cylinders is four, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com