A semi-automatic oled packaging line detection device and detection method

A semi-automated, detection device technology, applied in semiconductor/solid-state device testing/measurement, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of low detection efficiency and poor detection effect of packaging lines, and reduce unnecessary damage, lower inspection costs, and better visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail now in conjunction with accompanying drawing.

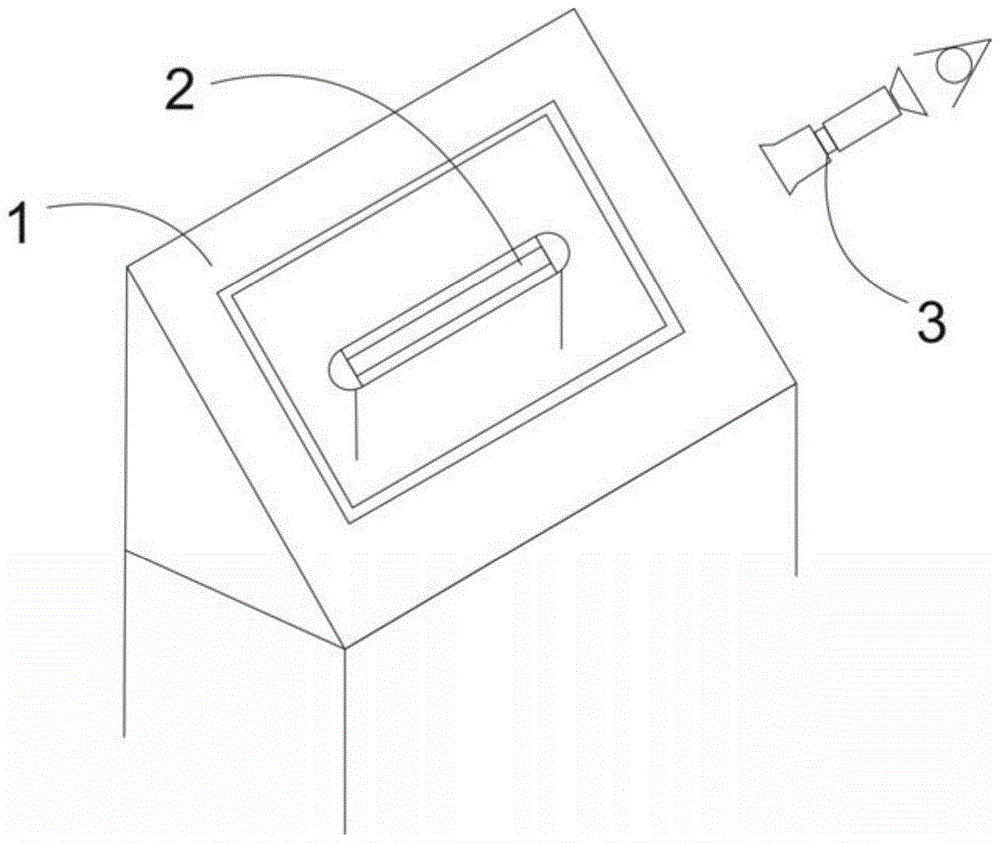

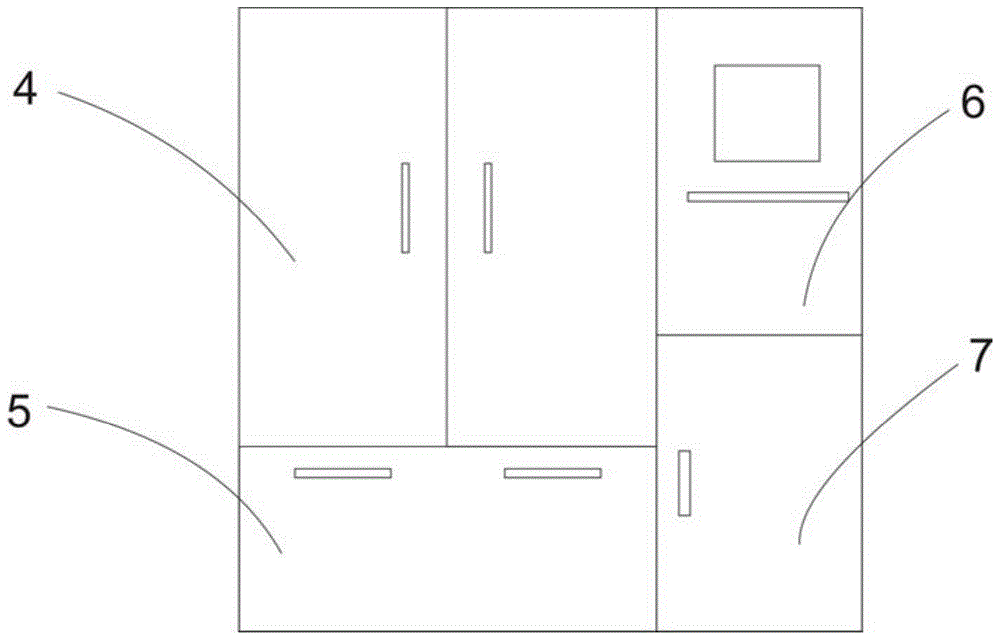

[0028] Such as figure 2 As shown, a semi-automatic OLED packaging line detection device includes a detection chamber 4, an electrical cabinet 5, a main control cabinet 6 and a drive cabinet 7, the main control cabinet 6 is electrically connected to the drive cabinet 7, and the electrical cabinet 5 is used to place the electrical structure .

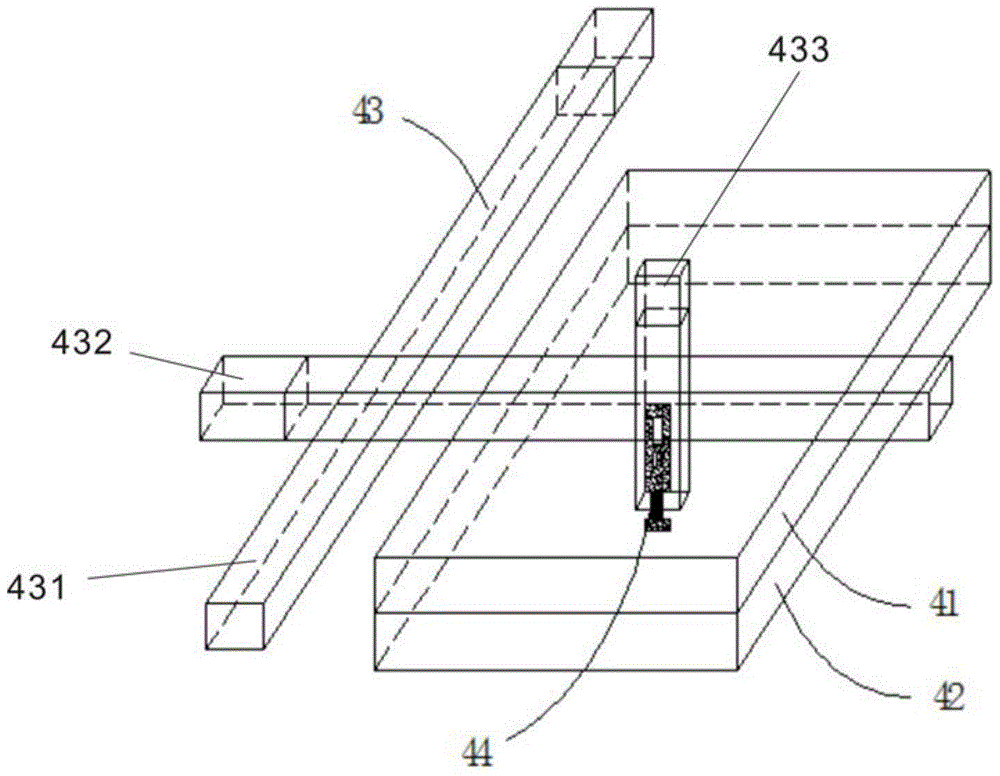

[0029] Such as image 3 As shown, the detection chamber 4 includes a vacuum adsorption table 41, a four-color backlight plate 42, a rectangular coordinate robot 43 and an industrial camera 44; the vacuum adsorption table 41 is set on the four-color backlight plate 42, and the rectangular coordinate robot 43 is suspended on the vacuum adsorption table 41 above, the industrial camera 44 is set on the rectangular coordinate robot 43; the vacuum adsorption table 41 is used to fix the OLED display to be tested, the four-color backligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com