Sealing component and container for power storage device

A sealing part and sealing technology, applied in electrochemical generators, battery pack parts, batteries, etc., can solve the problems of small volume ratio, low production efficiency, complex structure, etc., and achieve simple manufacturing equipment, efficient manufacturing, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

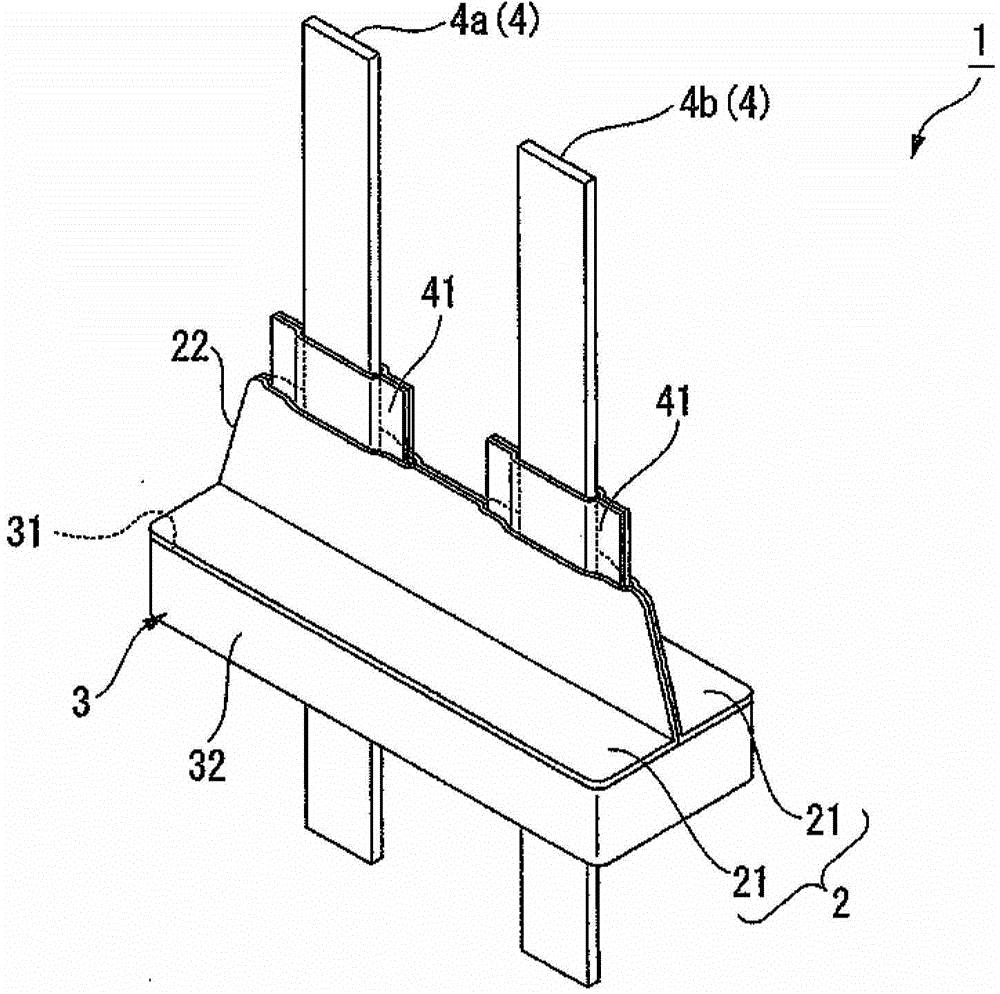

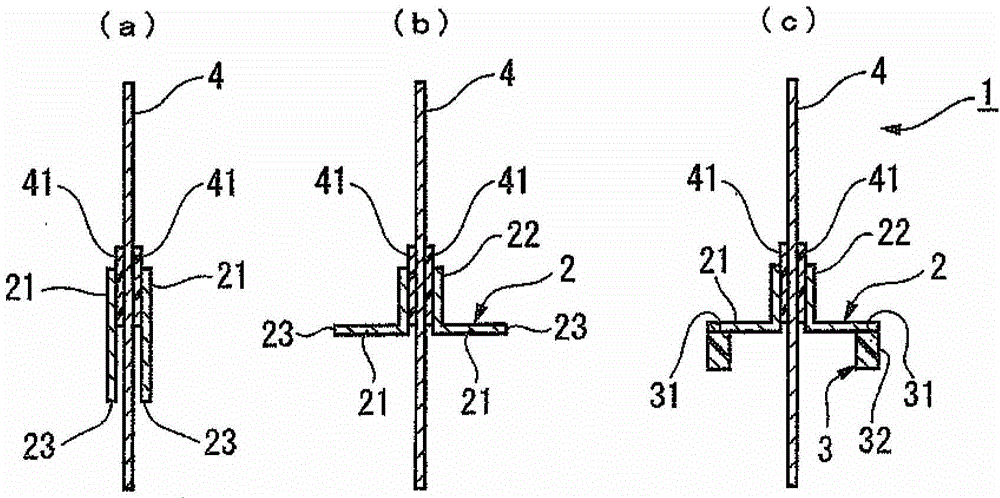

[0185] Example 1 is with Figure 1 ~ Figure 3 This is an example related to the first aspect shown.

[0186]

[0187] As the electrode terminal 4, a positive electrode terminal 4a made of aluminum foil having a width of 5 mm, a length of 50 mm, and a thickness of 0.2 mm and a negative electrode terminal 4b made of nickel-plated copper foil of the same size were used. As the insulating layer 41 , four insulating films composed of maleic anhydride grafted modified PP films with a width of 10 mm, a length of 12 mm and a thickness of 0.05 mm are used.

[0188] The electrode terminal 4a is sandwiched between two insulating films corresponding to the center line of the width and length, and a pair of hot plates are used to weld the insulating films as a whole to produce the electrode terminal 4a with an insulating layer 41 . The electrode terminal 4b with the insulating layer 41 is produced similarly.

[0189] For the electrode terminals 4a, 4b with the insulating layer 41, the ...

Embodiment 2

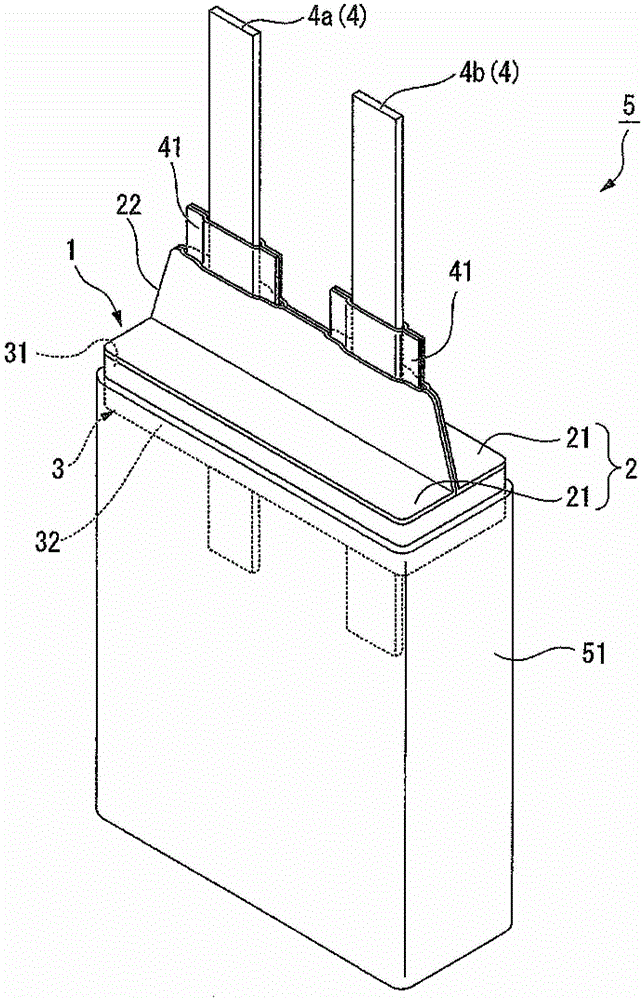

[0205] Example 2 is with Figure 4 ~ Figure 6 An example related to the second aspect shown. Example 2 is the same as Example 1 except that the configuration of the sealing wall 2 and the fixing configuration of the electrode terminals 4 are different. Hereinafter, only the different points will be described.

[0206]

[0207] The metal foil laminate produced in Example 1 was cut into a rectangle having a width of 50 mm and a length of 20 mm to produce a sealing wall 2 .

[0208]

[0209] The long sides of the produced sealing wall 2 and the long sides of the frame body 3 are aligned and overlapped. Between the sealing wall 2 and the frame body 3 , the electrode terminals 4 a and 4 b with insulating layers 41 used in Example 1 are arranged perpendicular to the long sides of the frame body 3 . When disposing, the insulation layers 41, 41 of the electrode terminals 4a, 4b are arranged in parallel with a distance of 8 mm, respectively located at positions 6 mm away from bo...

Embodiment 3

[0214] Example 3 is with Figure 7 ~ Figure 9 An example related to the third aspect shown. Example 3 is the same as Example 1 except that the form of the sealing wall 2 and the form of fixing the electrode terminal 4 are different. Hereinafter, only the different points will be described.

[0215]

[0216] The metal foil laminate produced in Example 1 was cut into a rectangle with a width of 50 mm and a length of 25 mm to produce a sealing wall 2 .

[0217]

[0218] The electrode terminal 4a used in Example 1 was sandwiched between the two insulating films used in Example 1 in the same manner as in Example 1. One end in the longitudinal direction of the two insulating films sandwiching the electrode terminal 4a was welded with a hot plate in a width of 5 mm across the entire width direction of the insulating films. The insulating films are welded to each other at both ends in the width direction of the insulating films where the electrode terminals 4a are not present a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com