Sol-gel coating comprising anisotropic particles and a culinary article provided with such a coating

An anisotropic, particle-based technology, used in the field of cooking equipment, can solve problems such as easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

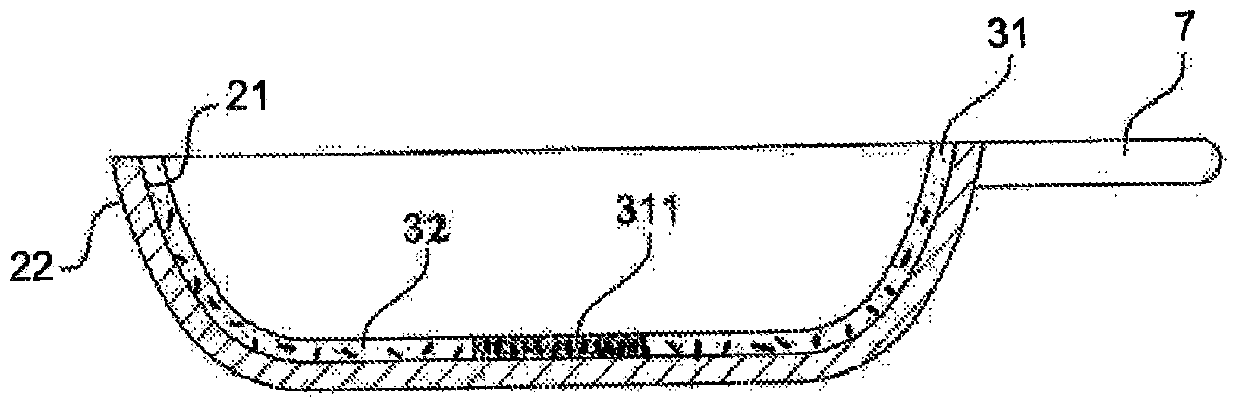

[0191] Achieving a single-layer coated film according to the invention comprising platelets substantially perpendicular to the film

[0192] A sol-gel mixture in the form of two components A+B was prepared in the same manner as in Comparative Example 2. The mixture was applied in the same manner as in Comparative Example 2 on a support made of sandblasted, degreased aluminum having a temperature of 60°C.

[0193] Conversely, immediately after application of the sol-gel mixture by spraying (but before baking), a magnetic field of 70 mT was applied by means of a permanent magnet arranged below the substrate. Under the action of a magnetic field, the mica flakes are oriented along the field lines, ie at the permanent magnet, due to their enveloping of magnetic iron oxide. It was observed that the wrapped mica flakes were mostly inclined at an angle α between 20° and 90° with respect to the film midplane.

[0194] Subsequently, the coating is baked at a temperature of 250° C. fo...

example 2

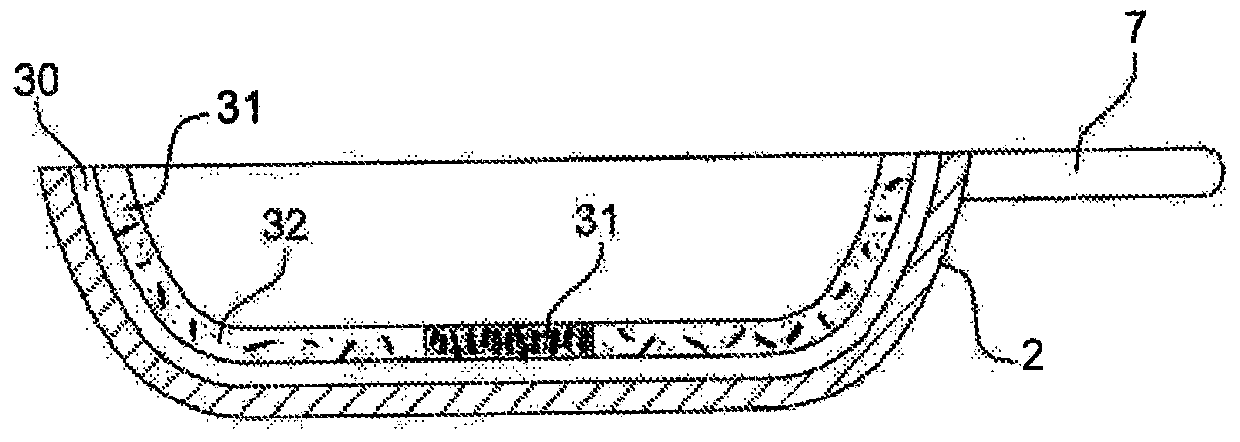

[0196] Achieving a double layer coated film according to the invention comprising platelets approximately perpendicular to the film

[0197] A colored sol-gel mixture and a colorless sol-gel mixture containing encapsulated mica flakes were prepared in a similar manner to Comparative Example 3. Also in the same manner as in Comparative Example 3, these mixtures were applied continuously on a support made of sandblasted, degreased aluminum having a temperature of 55°C.

[0198] Instead, immediately after application of the colorless sol-gel mixture by spraying (but before baking), a magnetic field of 70 Mt was applied by means of a permanent magnet arranged below the substrate. Under the action of a magnetic field, the mica flakes are oriented roughly vertically along the field lines, ie at the magnet, due to their enveloping of the magnetic iron oxide.

[0199] Subsequently, the coating is baked at a temperature of 280° C. for a period of at least 15 minutes.

[0200] Observa...

example 3

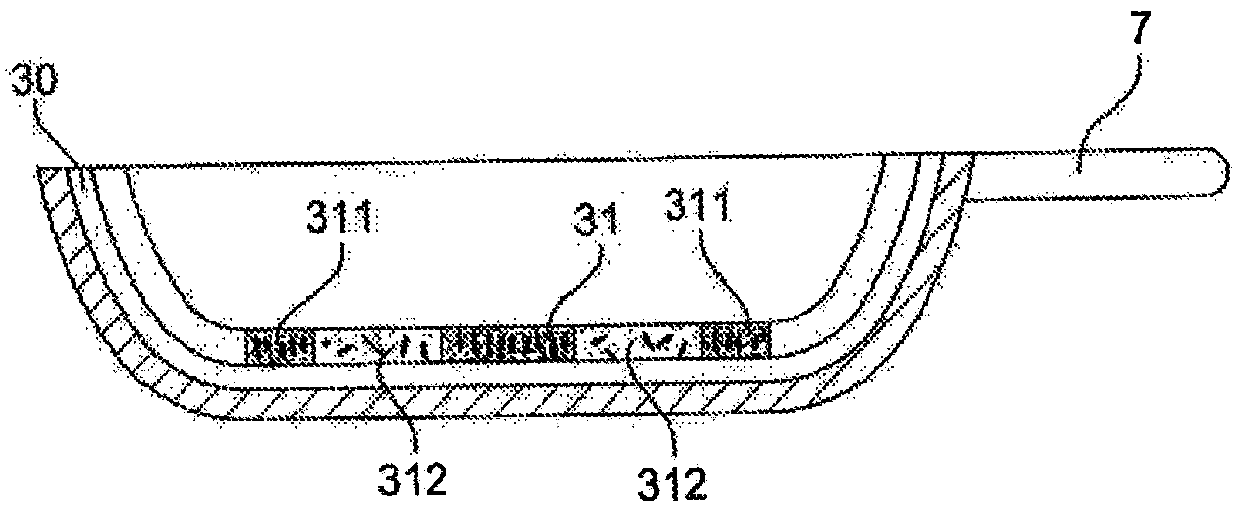

[0202] Achieving a double layer coated film according to the invention comprising microfibers approximately perpendicular to the film

[0203] This example differs from example 2 only in the shape of the particles in the final layer: a sheet wrapped in stainless steel microfibres is used instead.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com