A kind of thermally conductive silicone grease with self-adhesiveness and preparation method thereof

A heat-conducting silicone grease and self-adhesive technology, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of low viscosity, fluidity, and low self-adhesiveness of heat-conducting silicone grease, etc. Achieve good weather resistance, easy construction, good self-adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

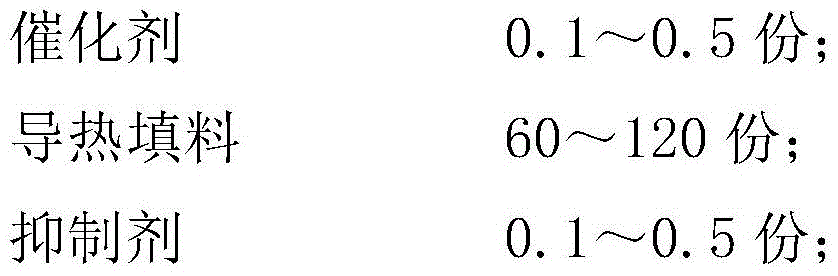

[0029] A self-adhesive heat-conducting silicone grease, its raw material formula is composed of the following components by weight:

[0030]

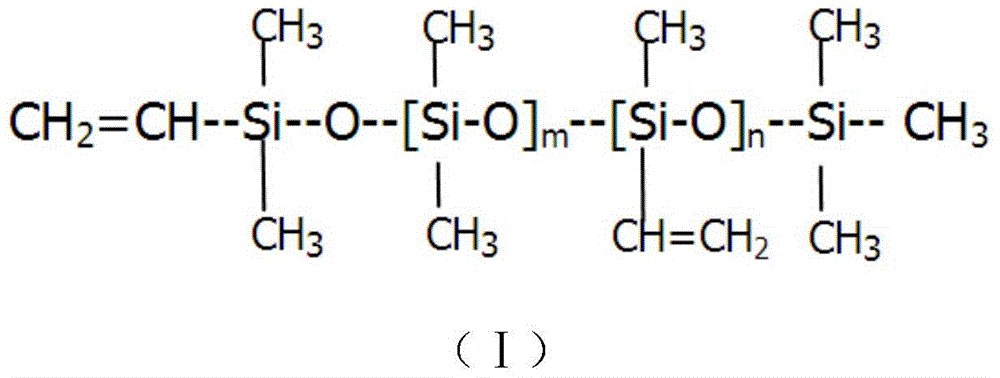

[0031] The structural formula of above-mentioned component A is as shown in general formula (I):

[0032]

[0033] In the above general formula (I), m=250, n=3;

[0034] The structural formula of component B is shown in general formula (II):

[0035]

[0036]

[0037] In the above general formula (II), p=10 and q=30.

[0038] Wherein, the catalyst is Castel platinum catalyst;

[0039] The thermal conductivity value of the thermally conductive filler is 37W / mK, and the particle size is 8-20nm;

[0040] The thermally conductive filler is alumina;

[0041] The inhibitor is methyl butynol.

[0042] The preparation method of the above-mentioned self-adhesive thermally conductive silicone grease comprises the following steps: Weigh component A, component B, catalyst, thermally conductive filler and inhibitor in a stirring tan...

Embodiment 2

[0048] A self-adhesive heat-conducting silicone grease, its raw material formula is composed of the following components by weight:

[0049]

[0050] The structural formula of above-mentioned component A is as shown in general formula (I):

[0051]

[0052] In the above general formula (I), m=260, n=4;

[0053] The structural formula of component B is shown in general formula (II):

[0054]

[0055] In the above general formula (II), p=15 and q=25.

[0056] Wherein, the catalyst is Castel platinum catalyst;

[0057] The thermal conductivity value of the thermally conductive filler is 125W / mK, and the particle size is 8-20nm;

[0058] The thermally conductive filler is boron nitride;

[0059] The inhibitor is a vinyl cyclic body.

[0060] The preparation method of the above-mentioned self-adhesive thermally conductive silicone grease comprises the following steps: Weigh component A, component B, catalyst, thermally conductive filler and inhibitor in a stirring tan...

Embodiment 3

[0066] A self-adhesive heat-conducting silicone grease, its raw material formula is composed of the following components by weight:

[0067]

[0068] The structural formula of above-mentioned component A is as shown in general formula (I):

[0069]

[0070] In the above general formula (I), m=280, n=5;

[0071] The structural formula of component B is shown in general formula (II):

[0072]

[0073] In the above general formula (II), p=10 and q=25.

[0074] Wherein, the catalyst is a platinum catalyst;

[0075] The thermal conductivity value of the thermally conductive filler is 270W / mK, and the particle size is 8-15um;

[0076] The thermally conductive filler is aluminum nitride;

[0077] The inhibitor is a vinyl cyclic body.

[0078]The preparation method of the above-mentioned self-adhesive thermally conductive silicone grease comprises the following steps: Weigh component A, component B, catalyst, thermally conductive filler and inhibitor in a stirring tank a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com