Foam discharge agent for gas well drainage and gas recovery

A technology of drainage and gas extraction and foam discharge agent, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problem that the foam discharge agent does not have low pH value and high temperature resistance performance, and the foam discharge agent does not have high resistance. Salt comprehensive performance and other issues, to achieve good water-carrying effect, excellent foaming performance, good foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

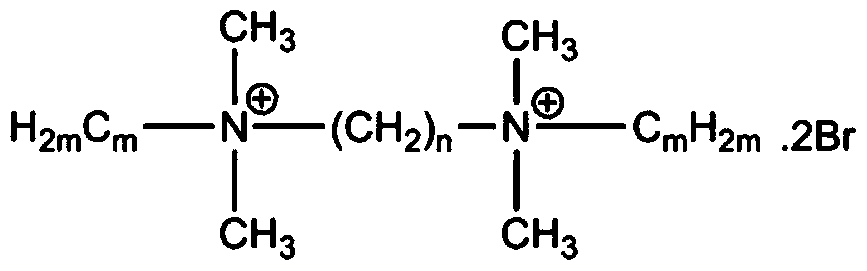

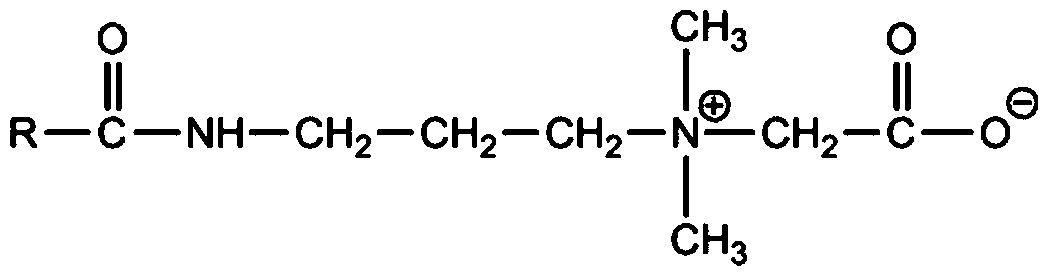

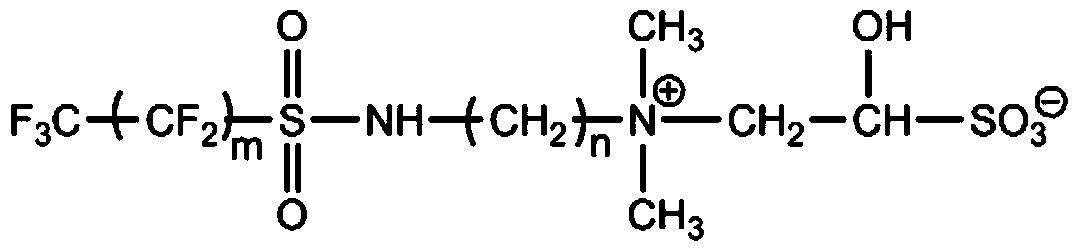

[0022] Add 15% mass quaternary ammonium salt gemini surfactant 12-3-12, 20% mass cocoamidopropyl betaine, and 2% mass fluorocarbon surfactant FS-73 into the reactor with agitator , 5% quality polyacrylamide (molecular weight 6×10 6 g / mol), 58% mass water, stir for 30 minutes to completely dissolve, and then obtain a wide pH, high temperature and high salt foam discharge agent for drainage and gas recovery. After 24 hours of high-temperature aging, the foam volume was tested by stirring.

Embodiment 2

[0024] Add 20% by mass quaternary ammonium salt gemini surfactant 16-4-16, 15% by mass lauroylaminopropyl betaine, and 1% by mass fluorocarbon surfactant FS-53, into a reactor with a stirrer. 7% quality polyacrylamide (molecular weight 1.2×10 7 g / mol), 57% water by mass, stir for 30 minutes to fully dissolve, and then obtain a wide pH, high temperature and high salt foam discharge agent for drainage and gas recovery. After 24 hours of high-temperature aging, the foam volume was tested by stirring.

Embodiment 3

[0026] Add 25% by mass quaternary ammonium salt gemini surfactant 14-6-14, 25% by mass cocoamidopropyl betaine, and 3% by mass fluorocarbon surfactant FS-73 in the reactor with agitator , 3% mass polyacrylamide (molecular weight 1×10 7 g / mol), 44% mass water, stir for 30 minutes to fully dissolve, and then obtain a wide-pH-value, high-temperature and high-salt foam discharge agent for drainage and gas recovery. After 24 hours of high-temperature aging, the foam volume was tested by stirring.

[0027] Examples 4 to 8 follow the methods of Examples 1, 2, and 3, the formulations are shown in Table 1 below, and the performance test results are shown in Table 2 below.

[0028] Table 1 Examples of foaming agents

[0029]

[0030] Table 2 The foaming ability, thermal stability, foam stability and other performance test results of the foaming agents of Examples 1-8

[0031]

[0032]

[0033] It can be seen from the data in Table 2 that the foaming agent for gas well drainage and recovery of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com