Device and method for carrying out microwave thermal desorption on oil-containing drilling cuttings

A thermal analysis and microwave technology, applied in the field of petrochemical industry, can solve the problems of uneven distribution of nitrogen, influence on deoiling rate, difference in deoiling rate, etc., and achieve the effect of improving the overall deoiling rate and improving uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

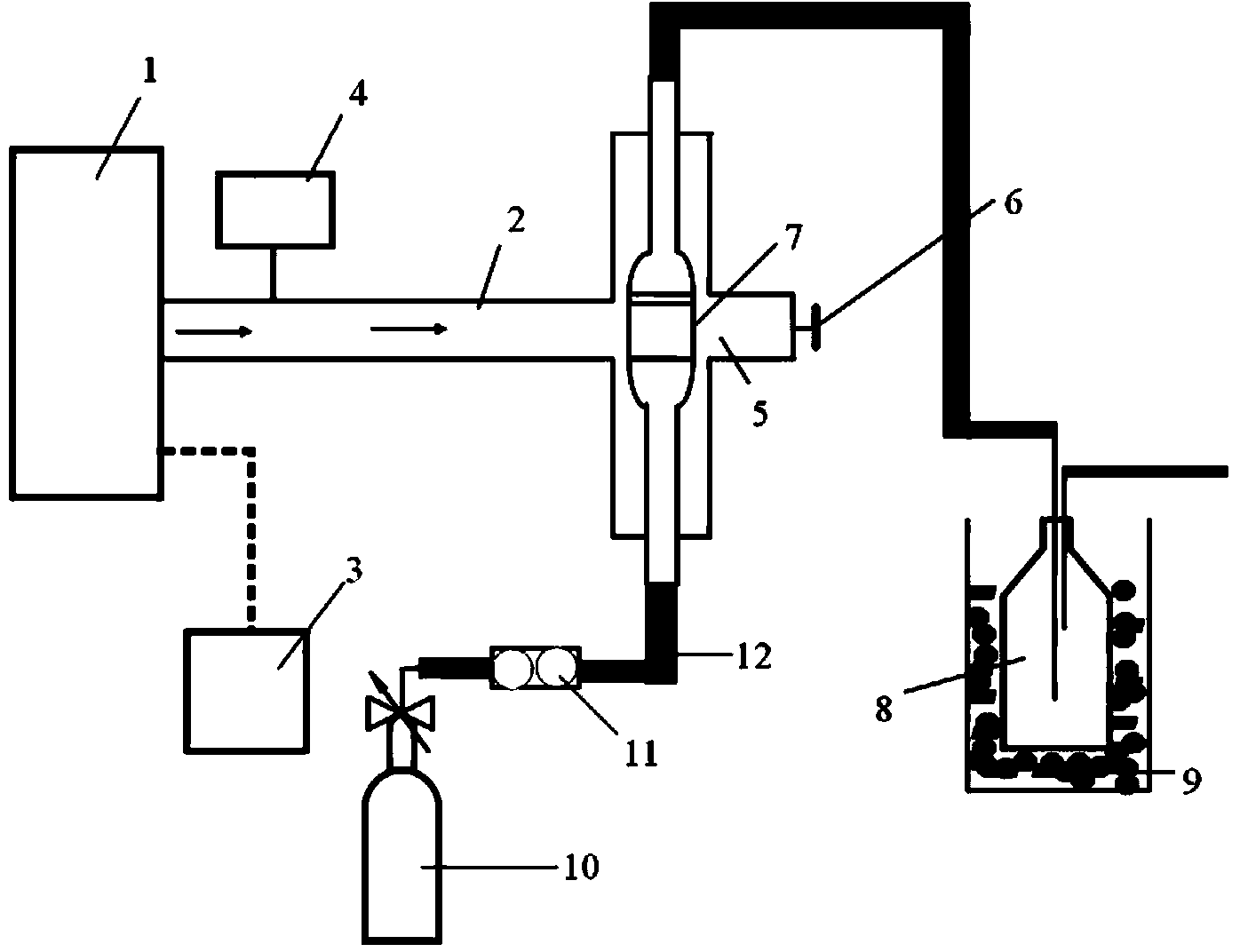

[0033] Such as figure 1 Shown is the apparatus diagram of the present invention.

[0034] The microwave generation and conduction unit is used to generate microwaves and conduct the generated microwaves to the reaction unit;

[0035] The reaction unit is used to receive the microwave from the microwave generation and conduction unit, and make it act on oily drill cuttings;

[0036] A nitrogen purge unit is used to flow the nitrogen gas flow into the reaction unit to remove air and entrain the oil gas produced by the reaction, and the nitrogen purge unit can control the flow rate of the nitrogen gas flow;

[0037] The condensation and separation unit is used to cool the oil and gas produced by the reaction to condense it into a liquid phase.

[0038] Among them, the microwave generation and conduction unit includes:

[0039] microwave generator 1;

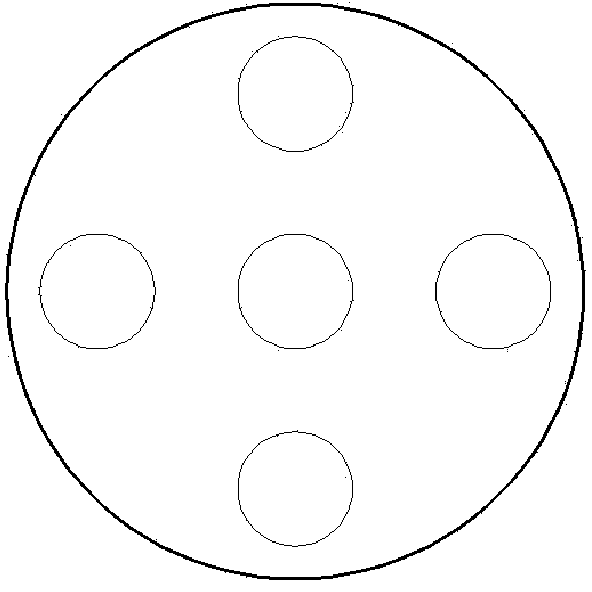

[0040] The waveguide converter 2 is connected to the microwave generator 1, and the waveguide converter 2 is also equipped wit...

Embodiment 2

[0050] Introduce the using method of device of the present invention in detail below:

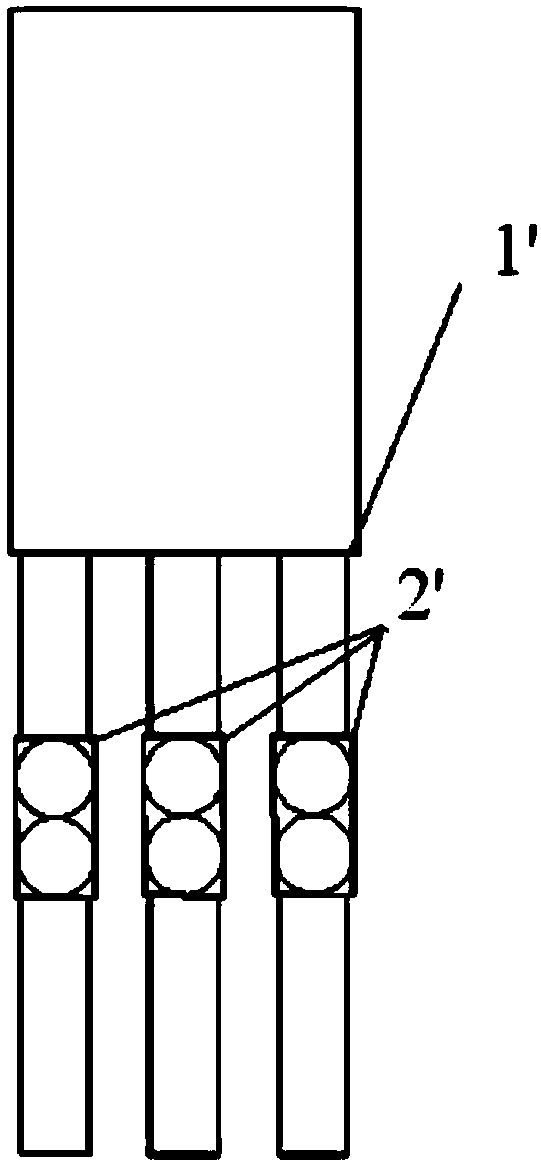

[0051] (1) Load an appropriate amount of oily cuttings into the lower part of the reactor 7. The oily cuttings are from Well Pengye 2, with an oil content of 15.3%, a water content of 4%, and a density of 2120kg / m 3 . The loading amount of oily drilling cuttings in the experiment is 30g. Then the upper and lower parts of the reactor 7 are sealed and placed in the single mold cavity 5 .

[0052] (2) Connect the five nitrogen pipelines 12 with the lower part of the reactor 7, then connect the receiver 8 with the upper part of the reactor 7, and check the airtightness of each connection.

[0053] (3) Turn on the microwave generator 1, set the microwave power used to 3kW, feed nitrogen at the same time, adjust the total rate of nitrogen to 1.5L / min, and adjust the nitrogen feed rate of each pipeline as required. Make the microwave act on oily drill cuttings at this power for 30 seconds. Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com