Total mixed ration for mutton sheep in?fattening?period and preparation method thereof

A full-mixing technology in the fattening period, which is applied in the design of animal nutrition and feed science, can solve problems such as unreasonable management and nutritional imbalance, and achieve the effects of improving health, improving overall uniformity, and improving immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

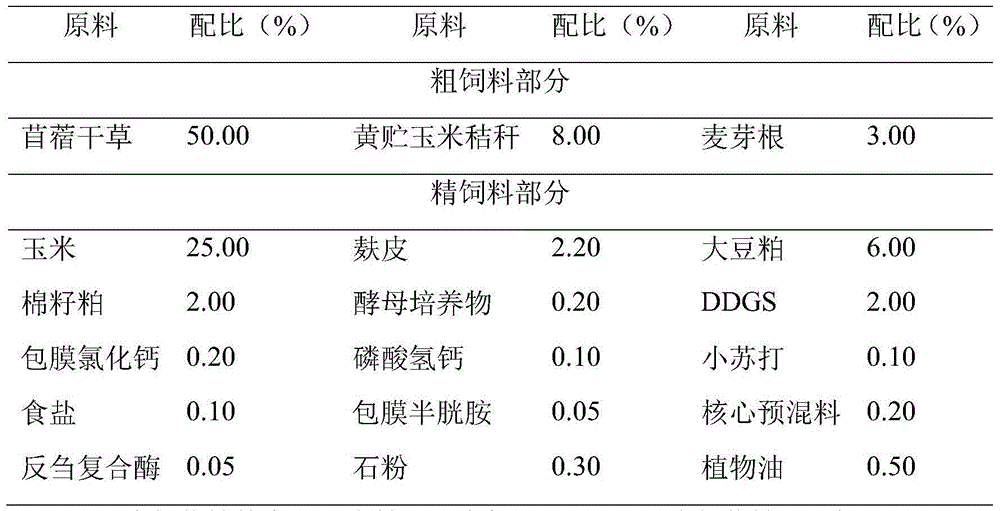

[0032] Embodiment 1: a kind of mutton sheep fattening period complete mixed feed comprises that by weight percentage is:

[0033]

[0034] The basic requirement of the alfalfa powder is that it meets the national standard GB10389 alfalfa powder quality standard level two or higher, crude protein ≥ 16.00%, crude fiber < 27.50%, and crude ash < 12.50%;

[0035] The basic requirements for the corn are grade 2 or above in line with the requirements of the national corn quality standard GB1353-2009, with bulk density ≥ 685.00g / L, imperfect kernel content ≤ 6.00%, raw mold kernel ≤ 2.00%, and impurities ≤ 1.00%;

[0036] The bran is first grade wheat bran, crude protein ≥ 15.00%, crude fiber < 9.00%, crude ash < 6.00%, in line with GB 6432-6439;

[0037] The basic requirement of the soybean meal is first-grade skinned soybean meal, crude protein ≥ 44.00%, urease activity (calculated as ammonia nitrogen) ≤ 0.3%, which meets the national standard for soybean meal for feed (GB / T 195...

Embodiment 2

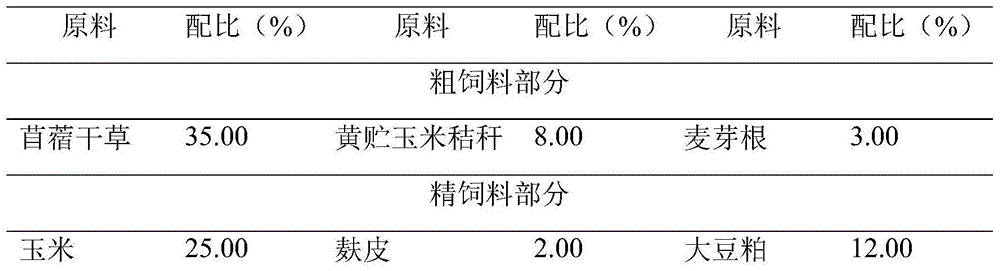

[0051] Embodiment 2: a kind of mutton sheep fattening period complete mixed feed comprises that by weight percentage is:

[0052] All the other are identical with embodiment 1 except proportioning.

[0053]

[0054]

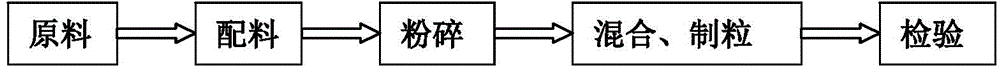

[0055] The preparation method of the above-mentioned mutton sheep fattening period full mixed feed, its steps are:

[0056] (1) Carry out pre-grinding treatment on alfalfa hay and corn raw material components, and the crushing particle size is 3.0 mm to 5.0 mm; according to the above-mentioned proportion by weight, mix evenly, and the coefficient of variation is ≤ 10.00%;

[0057] (2) Yeast culture, core premix, and ruminant compound enzyme ingredients are added to (1) according to the above proportion by weight;

[0058] (3) Use a mixer to process, and the mixing time is 12min to 14min.

[0059] (4) After passing the inspection, the fattening mutton sheep can be fed.

Embodiment 3

[0060] Embodiment 3: a kind of mutton sheep fattening period complete mixed feed comprises that by weight percentage is:

[0061] All the other are identical with embodiment 1 except proportioning.

[0062]

[0063] The preparation method of the above-mentioned mutton sheep fattening period full mixed feed, its steps are:

[0064] (1) Carry out pre-grinding treatment on alfalfa hay and corn raw material components, and the crushing particle size is 3.0 mm to 5.0 mm; according to the above-mentioned proportion by weight, mix evenly, and the coefficient of variation is ≤ 10.00%;

[0065] (2) Yeast culture, core premix, and ruminant compound enzyme ingredients are added to (1) according to the above proportion by weight;

[0066] (3) Use a mixer to process, and the mixing time is 12min to 14min.

[0067] (4) After passing the inspection, the fattening mutton sheep can be fed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com