A photocatalytic structure for splitting water and its manufacturing method

A manufacturing method, a technology of photolysis of water, which is applied in the field of photocatalysis, can solve the problems of not greatly improving, achieve low cost, simple structure and process, and solve the effect of low efficiency of photolysis of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

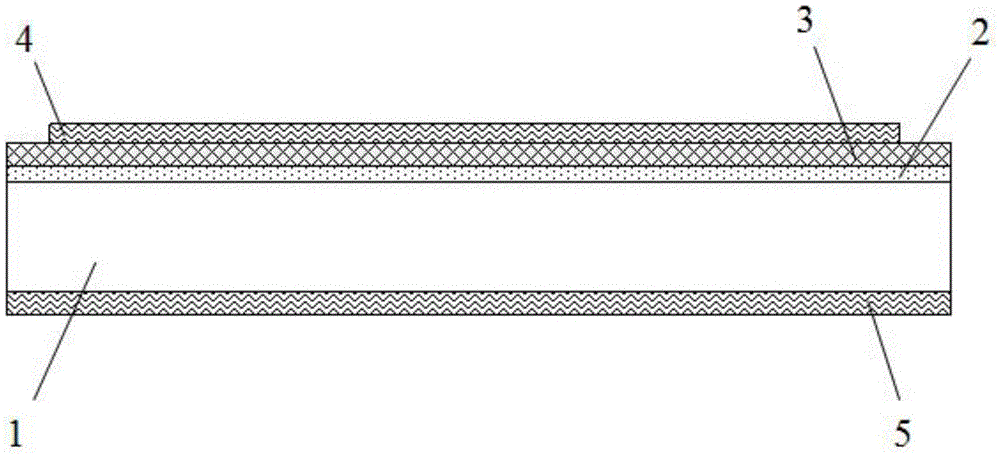

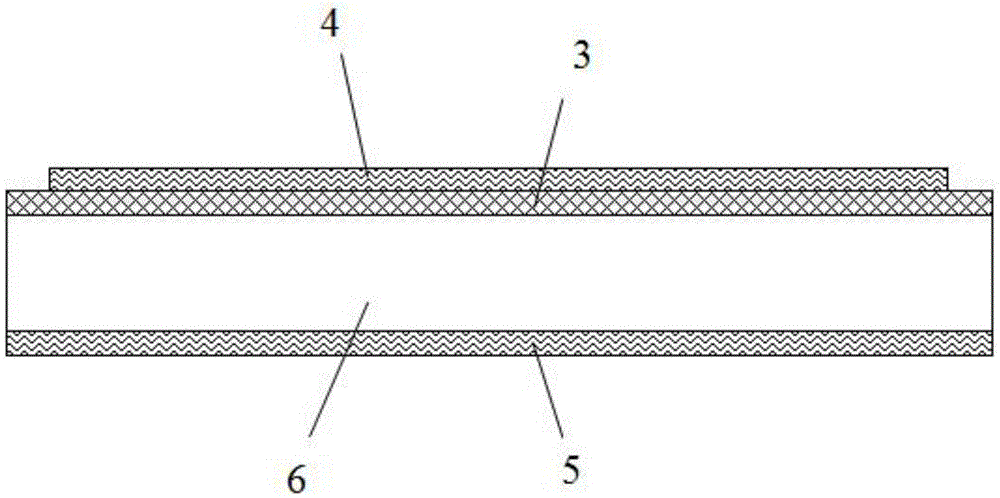

[0038] Please refer to figure 1 , figure 1 It is a schematic diagram of the structure of the photocatalytic water splitting of the present invention, such as figure 1 As shown, the photocatalytic structure of the present invention includes: a glass substrate 1; a conductive layer 2 located on the upper surface of the glass substrate 1 to form a conductive substrate, and the conductive layer 2 is fluorine-doped tin oxide or aluminum-doped oxide Zinc conductive film, the fluorine-doped tin oxide is 5% by mass or the aluminum-doped zinc oxide is 8% by mass, and the fluorine-doped tin oxide or aluminum-doped oxide is The thickness of the zinc conductive film is 50nm; the photocatalyst layer 3 is located on the upper surface of the conductive layer 2, and the photocatalyst layer 3 is pure α-Fe 2 o 3, whose thickness is 200nm; and a cover layer, which includes an upper cover layer 4 and a lower cover layer 5, the upper cover layer 4 is located on the upper surface of the photocat...

Embodiment 2

[0051] Please refer to figure 1 , figure 1 It is a schematic diagram of the structure of the photocatalytic water splitting of the present invention, such as figure 1 As shown, the photocatalytic structure of the present invention includes: a glass substrate 1; a conductive layer 2 located on the upper surface of the glass substrate 1 to form a conductive substrate, and the conductive layer 2 is fluorine-doped tin oxide or aluminum-doped oxide Zinc conductive film, the fluorine-doped tin oxide has a mass percentage of 7% or the aluminum-doped zinc oxide has a mass percentage of 9%, and the fluorine-doped tin oxide or aluminum-doped oxide The thickness of the zinc conductive film is 120nm; the photocatalyst layer 3 is located on the upper surface of the conductive layer 2, and the photocatalyst layer 3 is pure α-Fe 2 o 3 , whose thickness is 300nm; and a cover layer, which includes an upper cover layer 4 and a lower cover layer 5, the upper cover layer 4 is located on the up...

Embodiment 3

[0064] Please refer to figure 1 , figure 1 It is a schematic diagram of the structure of the photocatalytic water splitting of the present invention, such as figure 1 As shown, the photocatalytic structure of the present invention includes: a glass substrate 1; a conductive layer 2 located on the upper surface of the glass substrate 1 to form a conductive substrate, and the conductive layer 2 is fluorine-doped tin oxide or aluminum-doped oxide Zinc conductive film, the fluorine-doped tin oxide has a mass percentage of 8% by mass or the aluminum-doped zinc oxide has an aluminum-doped mass percentage of 10%, and the fluorine-doped tin oxide or aluminum-doped oxide The thickness of the zinc conductive film is 200nm; the photocatalyst layer 3 is located on the upper surface of the conductive layer 2, and the photocatalyst layer 3 is pure α-Fe 2 o 3 , whose thickness is 400nm; and a covering layer, which includes an upper covering layer 4 and a lower covering layer 5, the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com