Method of using robot for automatic welding of forged coupler yokes

A technology of automatic welding and welding methods, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of difficult welding root cleaning, unfused weld seams, hidden safety hazards, etc., and achieve saving welding materials and high welding pass rate Improvement, the effect of high welding surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

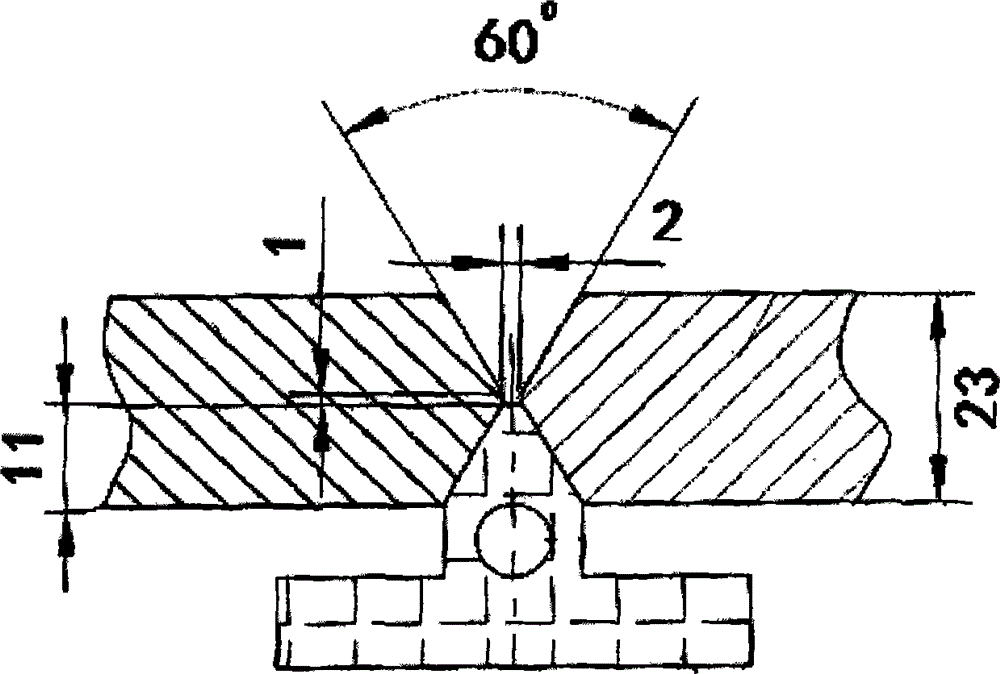

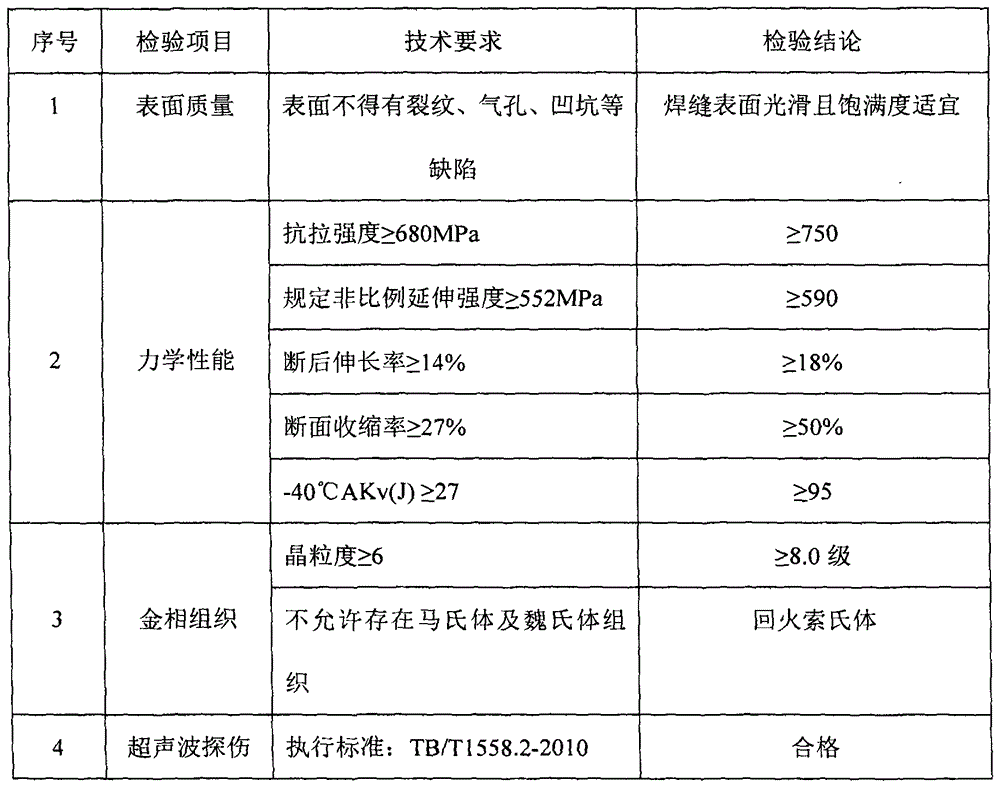

[0020] The forged coupler frame uses E36 steel plate. The parameters of the welded joint are: X-shaped groove, the blunt side of the groove is 2mm, and the groove angle is 60°. Before welding, degrease and clean the groove area.

[0021] The welding method includes the following steps: setting a water-cooled liner at the lower end of the X-shaped weld groove, and fixing the water-cooled liner flush with the center of the groove, and then opening the water-cooled liner arranged in the water-cooled liner. Cooling water circulation device; (2) at 90v%Ar+10v%CO 2 Under the atmosphere of the atmosphere, the welding robot (Panasonic automatic welding machine) is instructed to perform four passes of welding on the upper end of the weld groove. The welding currents of the first to fourth passes are 420A, 420A, 440A and 450A respectively, and the welding voltage Respectively 28V, 28V, 30V, 30V, the welding speed is 48cm / min, 48cm / min, 51cm / min, 52cm / min; 2 Under the gas, the welding r...

Embodiment 2

[0023] The forged coupler frame uses 15MnV steel plate. The parameters of the welded joint are: X-shaped groove, the blunt edge of the groove is 2mm, and the groove angle is 60°. Before welding, degrease and clean the groove area.

[0024] The welding method includes the following steps: setting a water-cooled liner at the lower end of the X-shaped weld groove, and fixing the water-cooled liner flush with the center of the groove, and then opening the water-cooled liner arranged in the water-cooled liner. Cooling water circulation device; (2) at 90v%Ar+10v%CO 2 Under the atmosphere of the atmosphere, the welding robot (Panasonic automatic welding machine) is instructed to perform four passes of welding on the upper end of the weld groove. The welding currents of the first to fourth passes are 420A, 420A, 440A and 450A respectively, and the welding voltage Respectively 28V, 28V, 30V, 30V, the welding speed is 48cm / min, 48cm / min, 51cm / min, 52cm / min; 2 Under the gas, the welding...

Embodiment 3

[0026] The forged coupler frame uses E36 steel plate. The parameters of the welded joint are: X-shaped groove, the blunt side of the groove is 2mm, and the groove angle is 60°. Before welding, degrease and clean the groove area.

[0027]The welding method includes the following steps: setting a water-cooled liner at the lower end of the X-shaped weld groove, and fixing the water-cooled liner flush with the center of the groove, and then opening the water-cooled liner arranged in the water-cooled liner. Cooling water circulation device; (2) at 90v%Ar+10v%CO 2 Under the atmosphere of the atmosphere, the welding robot (Panasonic automatic welding machine) is instructed to perform four passes of welding on the upper end of the weld groove. The welding currents of the first to fourth passes are 420A, 420A, 440A and 450A respectively, and the welding voltage Respectively 28V, 28V, 30V, 30V, the welding speed is 48cm / min, 48cm / min, 51cm / min, 52cm / min; 2 Under the gas, the welding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com