High-efficiency reactive sedimentation device for water treatment

A settling device and water treatment technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as poor sanitary conditions, short treatment time, complicated operation, etc., and achieve prolonged residence time, fast reaction speed, and long settling time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

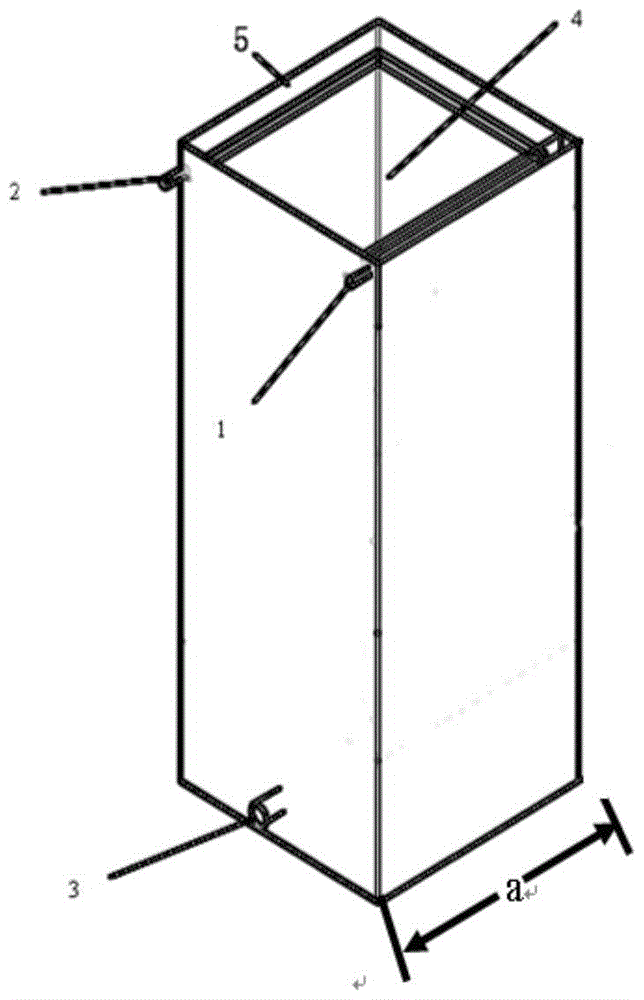

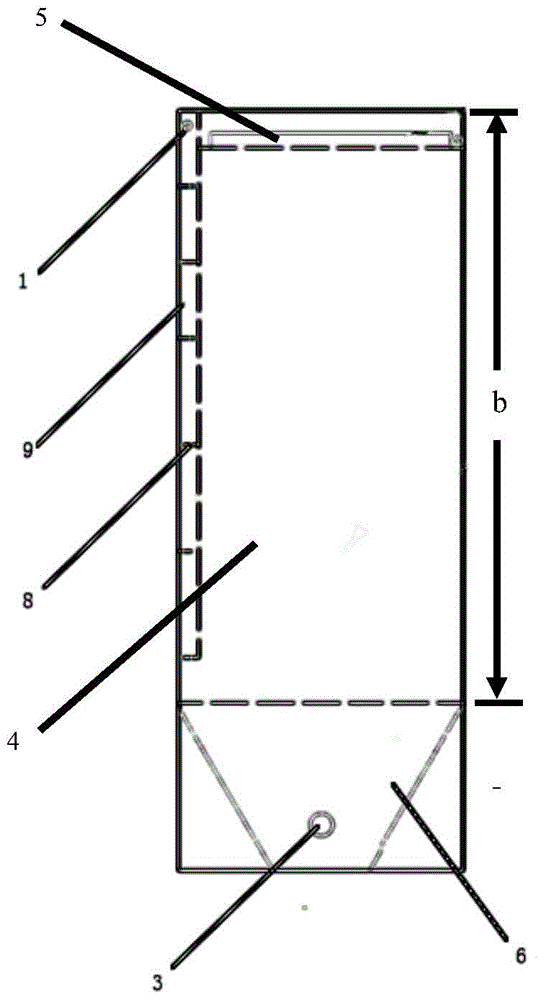

[0053] Such as figure 1 , 2 As shown, a high-efficiency reaction sedimentation device used in water treatment is composed of upper and lower parts. elliptical ring cylinder structure, polygonal structure, etc.), the cavity of the cuboid structure is the settlement zone 4; the lower part is the cavity of the conical funnel structure, and the cavity of the conical funnel structure is the sludge hopper 6;

[0054] Such as figure 2 Shown, be a sandwich chamber structure in a face of the chamber wall of upper cuboid structure, the interlayer chamber body is reaction zone 9, and the upper end of reaction zone 9 has sedimentation reactor water inlet 1, and the reaction zone 9 There is a reaction zone water outlet 7 at the lower end; a sedimentation reactor water outlet 2 is opened at the top of the sedimentation zone 4, and a sedimentation reactor sewage outlet 3 is opened at the bottom of the sludge hopper 6;

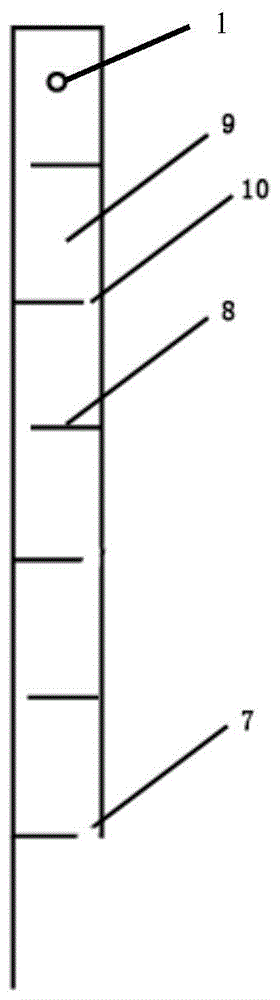

[0055] Such as image 3 As shown, in the reaction zone 9, the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com