Fire-resistant high temperature-resistant cable material and preparation method thereof

A high-temperature, cable-resistant technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of increased cable hardness, low elongation, outer layer fracture, etc., to improve processing performance, excellent stability, Good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A fire-resistant and high-temperature-resistant cable material, which is prepared from the following raw materials in parts by weight:

[0023] 80 parts of polyvinyl chloride, 10 parts of ethylene-vinyl acetate copolymer, 10 parts of methyl vinyl silicone rubber, 8 parts of GNA type neoprene rubber, 3 parts of epoxy fatty acid octyl ester, 2 parts of barium stearate, aluminum hydroxide 1 part, 1 part of compatibilizer, 0.5 part of flame retardant, 0.3 part of antioxidant, 0.1 part of bispentamethylenethiuram tetrasulfide and 0.1 part of trimethylolpropane trimethacrylate.

[0024] The preparation method of above-mentioned cable material comprises the steps:

[0025] 1) Preparation of base resin: Take polyvinyl chloride, ethylene-vinyl acetate copolymer, methyl vinyl silicone rubber, and GNA type neoprene and mix them evenly to obtain the main material in parts by weight, and place the main material in a single-screw extruder to share Mix and granulate to obtain the bas...

Embodiment 2

[0033] A fire-resistant and high-temperature-resistant cable material, which is prepared from the following raw materials in parts by weight:

[0034] 120 parts of polyvinyl chloride, 15 parts of ethylene-vinyl acetate copolymer, 15 parts of methyl vinyl silicone rubber, 12 parts of GNA type neoprene rubber, 5 parts of epoxy fatty acid octyl ester, 3 parts of barium stearate, aluminum hydroxide 2 parts, 2 parts of compatibilizer, 0.8 part of flame retardant, 0.5 part of antioxidant, 0.2 part of bispentamethylene thiuram tetrasulfide and 0.2 part of trimethylolpropane trimethacrylate.

[0035] The preparation method of above-mentioned cable material comprises the steps:

[0036] 1) Preparation of base resin: Take polyvinyl chloride, ethylene-vinyl acetate copolymer, methyl vinyl silicone rubber, and GNA type neoprene and mix them evenly to obtain the main material in parts by weight, and place the main material in a single-screw extruder to share Mix and granulate to obtain th...

Embodiment 3

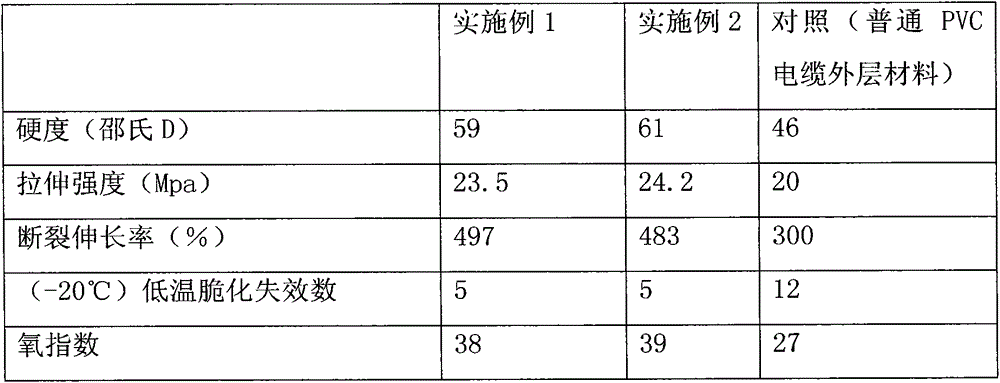

[0044] The refractory and high temperature resistant material prepared in embodiment 1-2 is subjected to a performance test, and the test results are as follows:

[0045] Table 1

[0046]

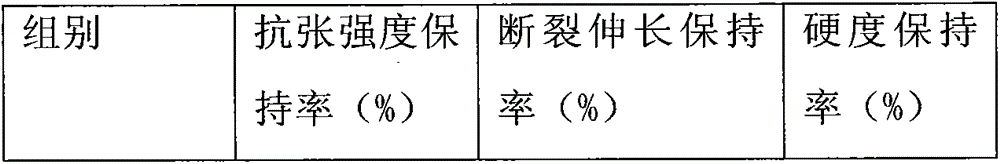

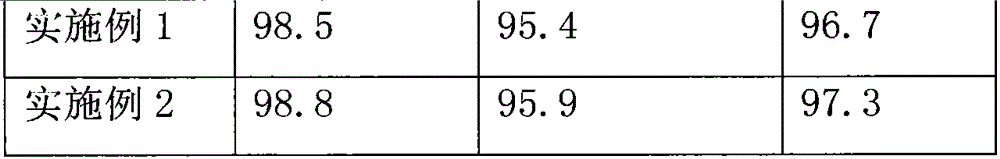

[0047] Performance test of the cable materials prepared in Examples 1 and 2 under extreme high temperature conditions: the selected temperature is 120°C, and the cable materials are placed at this temperature for 30 days for measurement. The test results are shown in Table 2:

[0048] Table 2

[0049]

[0050]

[0051] Conclusion: The performance of the cable material prepared by the present invention is better in all aspects, and the performance parameters of various aspects do not change much under high temperature conditions, and are suitable for long-term use under extreme high temperature conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com