Antibacterial, deodorizing polyester biodegradable food rolling bag as well as preparation and application of rolling bag

A biodegradable, rolling bag technology, applied in the field of polymers, can solve the problems of pollution, waste of resources, and the inability of rolling bags to be completely equal, and achieve the effect of improving the urban landscape environment and eliminating white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Copolyester 1 obtained from terephthalic acid, 1,4-butanediol and adipic acid as main monomers. The color and transparency are good, and there are few impurities. The molecular weight Mn measured by GPC is 75,100, and the molecular weight distribution (PI) is 2.5.

[0034] According to JIS K7210, at 280 o C and under the load of 2.16Kg, the MFR is 40g / 10min.

[0035] 100Kg copolyester 1, 10Kg polylactic acid (trade name is 4032D produced by Naturework Company), 0.30Kg antioxidant 168, 15Kg silicon dioxide, 1.5KgUV-531, 2.0Kg nano silver antibacterial agent, 6Kg lubricant EBS, 1.5Kg of anti-fogging agent polyethylene glycol is mixed evenly, and then blown by a film blowing machine to obtain antibacterial and odor-removing polyester biodegradable food roll 1.

[0036] Light transmittance, flexibility and appearance are good (◎).

[0037] Appearance evaluation (by visual judgment)

[0038] No flow marks or very inconspicuous ◎

[0039] Flow marks are not obvious ○

...

Embodiment 2-6

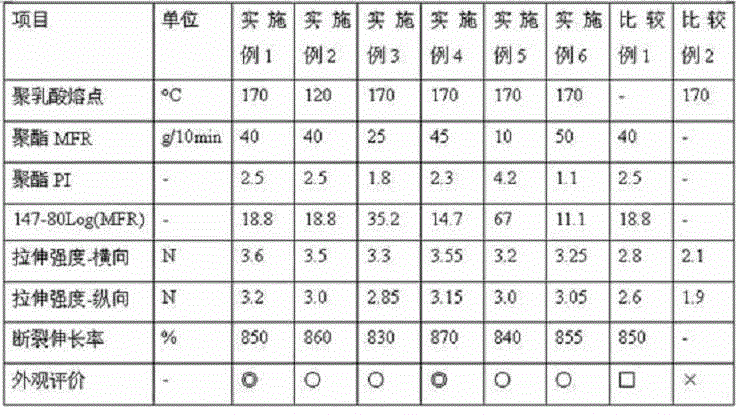

[0046] The difference with embodiment 1 is shown in table 1, and others are with embodiment 1.

[0047] Table 1

[0048]

Embodiment 7

[0050] Copolyester 2 obtained from 1,5-naphthalene dicarboxylic acid, 1,4-butanediol and adipic acid as main monomers. The color and transparency are good, and there are few impurities. The molecular weight Mn measured by GPC is 70,000, and the molecular weight distribution (PI) is 2.0.

[0051] .

[0052] Wherein Comparative Example 1 adopted polyester without adding polylactic acid. What comparative example 2 adopts is polylactic acid, does not add polyester.

[0053] Through the comparison of Example 1 and Comparative Examples 1 and 2, it can be seen that the performance of the product obtained by blending copolyester and polylactic acid is obviously better than that of a single copolyester or polylactic acid product. Such as mechanical strength, appearance evaluation.

[0054] Through the comparison of Examples 1 and 2, it can be seen that the selection of the melting point of polylactic acid has a certain influence on the mechanical strength of the product, but has lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com