A kind of washing-resistant composite antibacterial metal coating and preparation method thereof

A composite antibacterial and metal coating technology, which is applied in polyester coatings, epoxy resin coatings, antifouling/underwater coatings, etc., can solve environmental restrictions on antibacterial effects, poor scrub resistance of antibacterial coatings, and short antibacterial timeliness, etc. problem, to achieve enhanced scrub resistance and antibacterial performance, excellent antibacterial performance, improved activity and application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

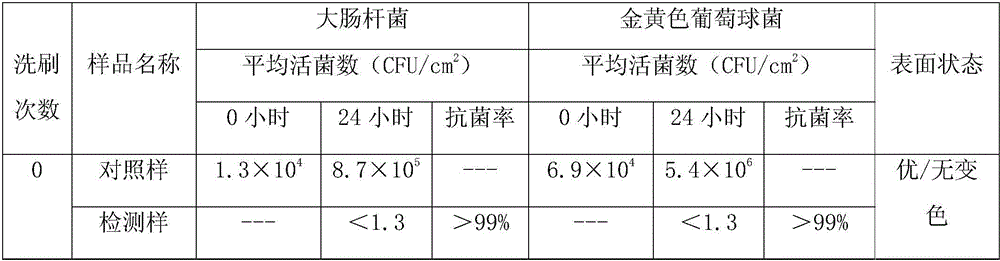

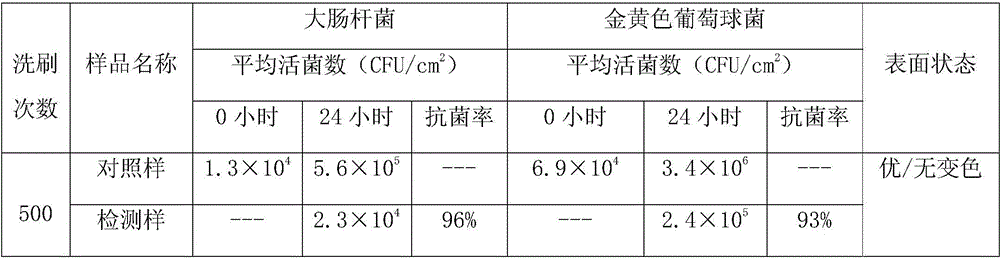

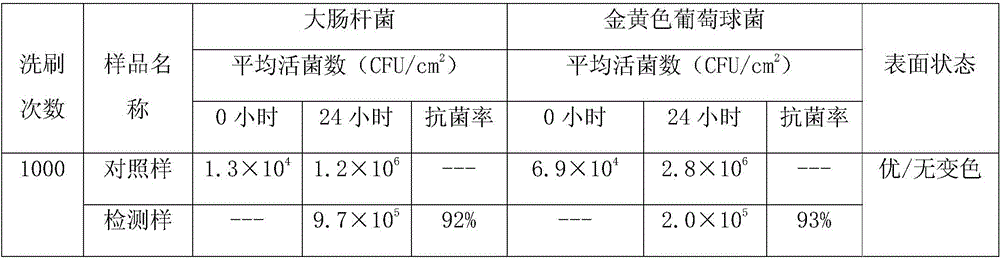

Examples

Embodiment 1

[0016] A kind of wash-resistant metal antibacterial paint, its prescription is made up of following weight percent: modified polyester resin 19%, modified epoxy resin 21%, modified styrene-acrylic emulsion 13%, coupling agent 7%, nano titanium dioxide sol 28%, metal ion solution 12%. Its preparation method comprises the following steps:

[0017] 1) Weigh silver nitrate equivalent to 0.001mol quality, add it into a mixed solvent of 20ml ethanol and 80ml deionized water, stir rapidly until the metal salt solid is completely dissolved, and obtain an organic / deionized water mixed solution containing metal ions;

[0018] 2) Slowly add a certain amount of modified styrene-acrylic emulsion and coupling agent to the above-mentioned antibacterial metal ion solution under the state of high-speed stirring of the disperser and a constant temperature of 40-70°C, and stir until uniform, and prepare the first solution;

[0019] 3) Add 15ml of tetrabutyl titanate into 50ml of ethanol, slowly...

Embodiment 2

[0023] A kind of wash-resistant metal antibacterial paint, its prescription is made up of following weight percent: modified polyester resin 15%, modified epoxy resin 23%, modified styrene-acrylic emulsion 9%, coupling agent 9%, nano titanium dioxide Sol 31%, metal ion solution 13%, its preparation method comprises the following steps:

[0024] 1) Weigh copper nitrate equivalent to 0.001mol quality, add it to 20ml propylene glycol butyl ether and 80ml ethanol mixed solvent, stir rapidly until the metal salt solid is completely dissolved, and obtain an organic / deionized water mixed solution containing metal ions;

[0025] 2) Slowly add a certain amount of modified styrene-acrylic emulsion and coupling agent to the above-mentioned antibacterial metal ion solution under the state of high-speed stirring of the disperser and a constant temperature of 40-70°C, and stir until uniform, and prepare the first solution;

[0026] 3) Add 15ml of tetrabutyl titanate into 50ml of deionized w...

Embodiment 3

[0030] A kind of wash-resistant metal antibacterial paint, its prescription is made up of following weight percent: modified polyester resin 17%, modified epoxy resin 19%, modified styrene-acrylic emulsion 12%, coupling agent 8%, nano titanium dioxide Sol 30%, metal ion solution 14%. Its preparation method comprises the following steps:

[0031] 1) Weigh zinc nitrate equivalent to a quality of 0.001mol, add it to a mixed solvent of 20ml ethanol, 20ml propylene glycol butyl ether and 60ml deionized water, and stir rapidly until the metal salt solid is completely dissolved to obtain an organic / deionized solution containing metal ions. Ionized water mixed solution;

[0032] 2) Slowly add a certain amount of modified styrene-acrylic emulsion and coupling agent to the above-mentioned antibacterial metal ion solution under the state of high-speed stirring of the disperser and a constant temperature of 40-70°C, and stir until uniform, and prepare the first solution;

[0033] 3) Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com