Ceramic material use abrasive

A technology of ceramic materials and abrasives, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of weak lubricating ability of water-based abrasives, environmental pollution and high cost, and unsmooth grinding process, so as to reduce scratches Probability, improved grinding efficiency, good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The abrasives for ceramic materials of the present application will be described in detail below through specific examples. It should be noted that the examples are only used to illustrate the composition, content and preparation method of the abrasive, and do not limit the protection scope of the present application in any way.

[0018] The abrasive for ceramic materials described in the present application contains a film-forming agent, an auxiliary film-forming agent, abrasive particles, and water. The film forming agent is selected from one or both of lower polyols and alcohol amines, the auxiliary film forming agent is selected from one or both of borate and lithium chromate, and the abrasive particles for borides. The mass ratio among the film-forming agent, auxiliary film-forming agent, grinding particles and water is 10-30:0.2-4:0.1-3:70-90. Preferably, the mass ratio between the film-forming agent, auxiliary film-forming agent, abrasive particles and water is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

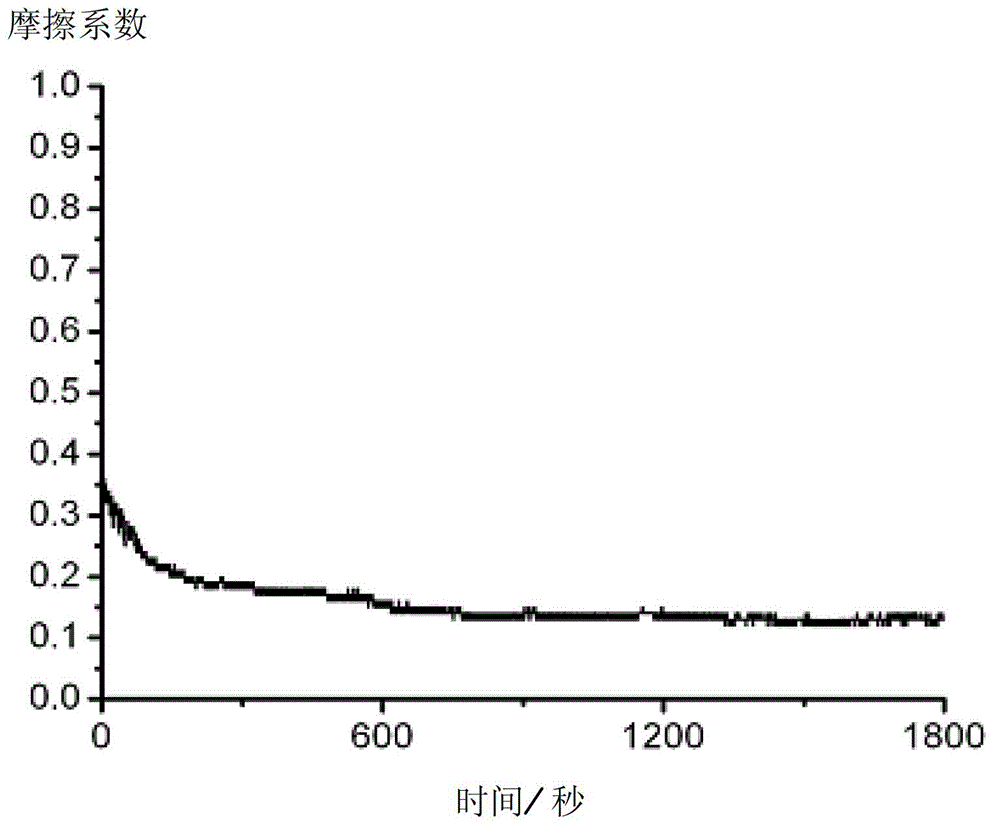

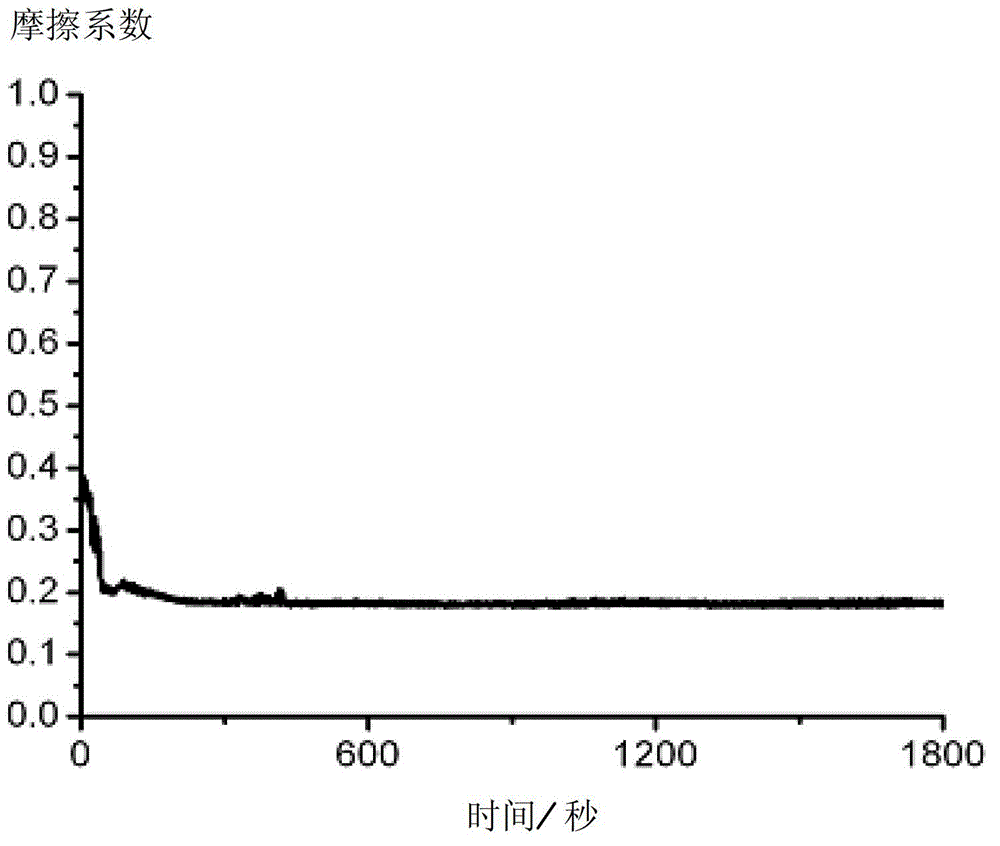

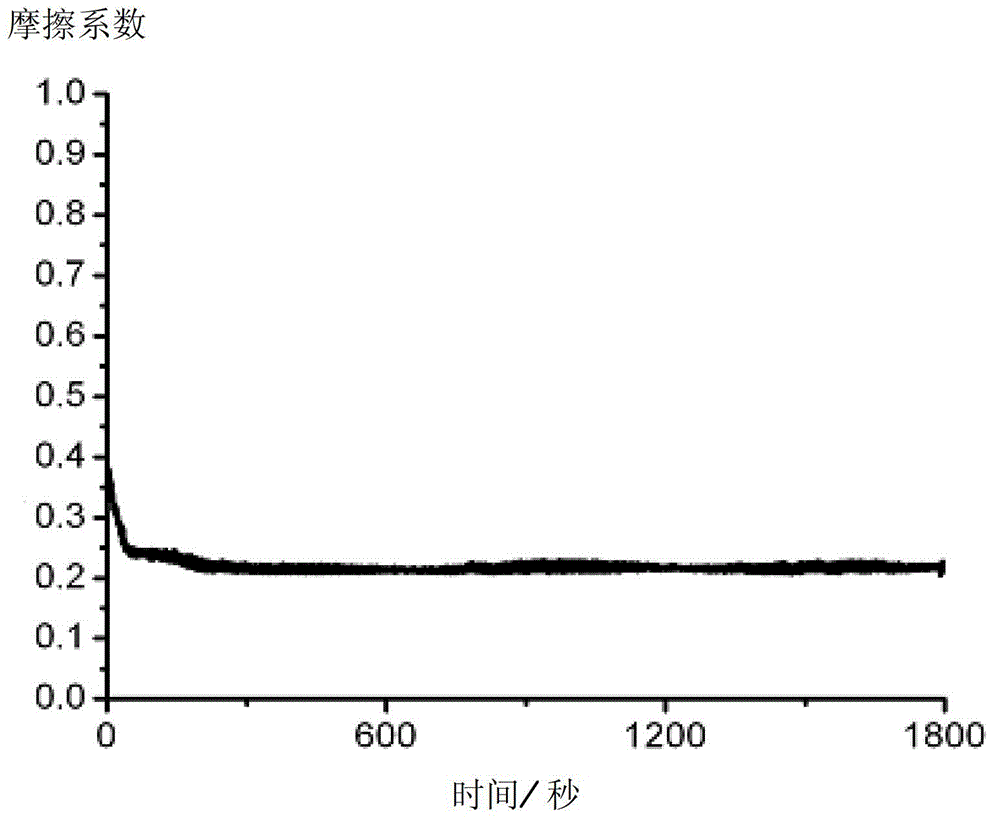

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com