A kind of method for splitting and preparing optically pure r-1-phenethylamine

A phenethylamine and optical technology, which is applied in the field of separation and preparation of optically pure R-1-phenethylamine, can solve the problems of low utilization rate, high cost, and difficulty in obtaining, and achieves good optical purity and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

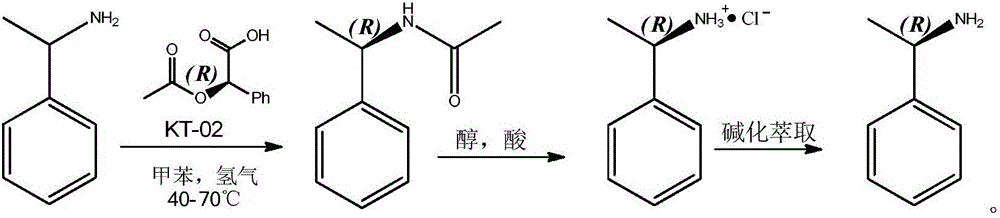

[0008] 1) Resolution and preparation of (R)-(1-phenylethyl)acetamide

[0009] Add 500mL of toluene into a 1000mL autoclave as a solvent, add 60.5g of 1-phenylethylamine, 106.7g of D-(-)-O-acetylmandelic acid, 5g of lipase Novozym 435 and 8g of KT-02 in sequence, and seal the After the autoclave, the air in the autoclave was replaced with nitrogen, and then hydrogen gas was introduced into the autoclave to a pressure of 1.0MP. Stirring was started, and the temperature was raised to 60°C for reaction; after 19 hours, a sample was taken to detect that 1-phenylethylamine disappeared completely Convert to (R)-(1-phenylethyl)acetamide, and the ee value of the product reaches 99%; after the reaction is completed, the solution is concentrated, and then mixed solvent with n-hexane and ethanol with a volume ratio of 10:1 Column chromatography was carried out to obtain 102.3 g of pure (R)-(1-phenylethyl)acetamide, with a yield of 96%.

[0010] 2) Acid hydrolysis to obtain R-1-phenethyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com