A device for improving yarn structure by moist heat drafting and smoothing

A drafting and yarn technology, which is applied in the field of wet heat drafting and smoothing device to improve yarn structure, to achieve the effects of eliminating internal fiber hooks, increasing internal fiber orientation, and improving yarn strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

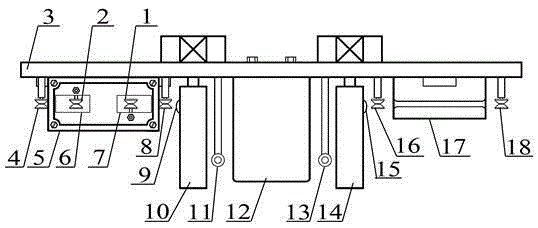

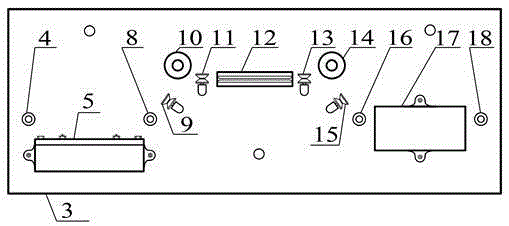

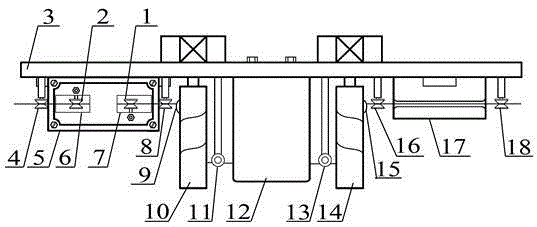

[0019] Example 1: Applied in the winding process to improve the structure of ring-spun yarn

[0020] The device for improving the yarn structure by moist heat drafting and smoothing is fixedly installed between the bobbin package and the yarn guide hook of the 1332M-D100 domestic winder through the main mounting plate 3, and the 40-inch yarn unwound from the bobbin package The pure cotton ring-spun bobbin is guided into the infiltration tank device 5 by the first yarn guide wheel 1, and is effectively immersed in the infiltration tank device 5 by 3.5% under the action of the first yarn dipping wheel 1 and the second yarn dipping wheel 2 In the JFC aqueous solution, full infiltration is realized. After the infiltration treatment, the yarn is drawn out through the second yarn guide wheel 8, and the yarn is wound in a helical circle of 3-6 turns on the rear roller 10 through the third yarn guide wheel 9, and wound on the The yarn on the back roller 10 enters the heating tank of t...

example 2

[0021] Example 2: Applied in the warping process to improve the yarn structure

[0022]The device for improving the yarn structure by moist heat drafting and smoothing is fixedly installed on a row of yarn guide rods at the yarn output end of the creel of the warping machine through the main mounting plate 3, and the yarn unwound from the yarn package of the warping frame The 30 public count pure wool bobbin is guided into the infiltration tank device 5 by the first yarn guide wheel 1, and is effectively immersed in the infiltration tank device 5 by 5% under the action of the first yarn dipping wheel 1 and the second yarn dipping wheel 2 In the JFC aqueous solution, full infiltration is realized. After the infiltration treatment, the yarn is drawn out through the second yarn guide wheel 8, and the yarn is wound in a helical circle of 3-6 turns on the rear roller 10 through the third yarn guide wheel 9, and wound on the The yarn on the back roller 10 enters the heating groove o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com