Manufacturing method for softly-covered wall and softly-covered wall

A technology of soft package and glass magnesium board, which is applied in the field of decorative materials, can solve the problems of insufficient hardness, softness and easy deformation, poor sound insulation effect, etc., and achieve the effect of convenient application, overcoming insufficient hardness, and good sound absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

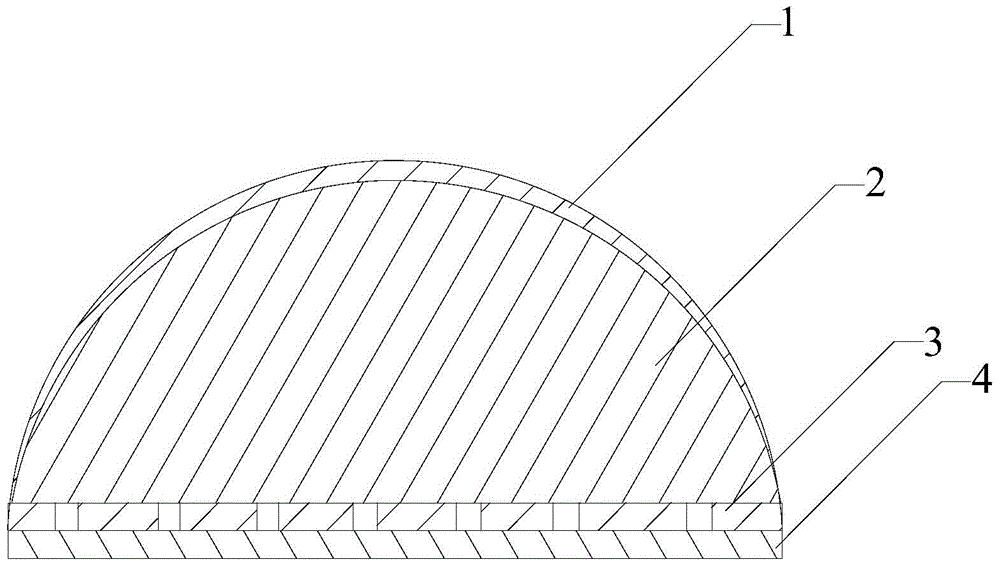

[0020] The preparation method of a kind of wall surface soft package of the present invention, the glass magnesium plate is drilled and then sealed, the polyurethane foam material is injected into the surface layer of the wall surface soft package with a cavity, and the sealed glass The magnesium plate is covered with the surface layer of the wall soft package to seal the polyurethane foam material, and then undergoes a foaming reaction. After the foaming reaction, the sealed glass magnesium plate is through-holed to obtain the wall surface soft package.

[0021] As can be seen from the above description, the beneficial effects of the preparation method of the soft wall bag of the present invention are:

[0022] (1) The glass magnesium board is used as the raw material to replace the PVC composite board as the backboard of the wall soft package, thereby overcoming the insufficient hardness of the wall soft package of the PVC composite board backboard in the prior art, low tempe...

Embodiment 1

[0045] (1) flatten the leather and place it on the mould;

[0046] (2) Pouring polyurethane foam into the leather placed on the mould; the polyurethane foam includes two components of isocyanate and combined polyether, commonly known as black material and white material, also known as PU material, hair Foaming material, composite material, black oil butter.

[0047] (3) The glass magnesium board is first drilled, and then sealed, and the sealed glass magnesium board is covered with the leather placed on the mould, and the foaming reaction is carried out. The time of the foaming reaction is 4min. The foaming temperature is 30° C., and then the holes are subjected to through-hole treatment, and left to stand for 1 min to obtain a soft wall package.

Embodiment 2

[0049] (1) flatten the leather and place it on the mould;

[0050] (2) Polyurethane foaming material is poured into the leather placed on the mould;

[0051](3) The glass magnesium board is first drilled, and then sealed, and the sealed glass magnesium board is covered with the leather placed on the mould, and the foaming reaction is carried out. The time of the foaming reaction is 6 minutes. The foaming temperature is 40°C, and then the holes are subjected to through-hole treatment, and left to stand for 10 minutes to obtain a soft wall package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com