Power transmission line covered ice monitoring device based on rotation reference conductor

A transmission line and monitoring device technology, applied in the field of electric power equipment, can solve the problems of reducing the timeliness and accuracy of monitoring results, demanding camera installation angles, and increasing the labor intensity of patrol personnel, so as to ensure the stability and reliability of power supply, Improved timeliness and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

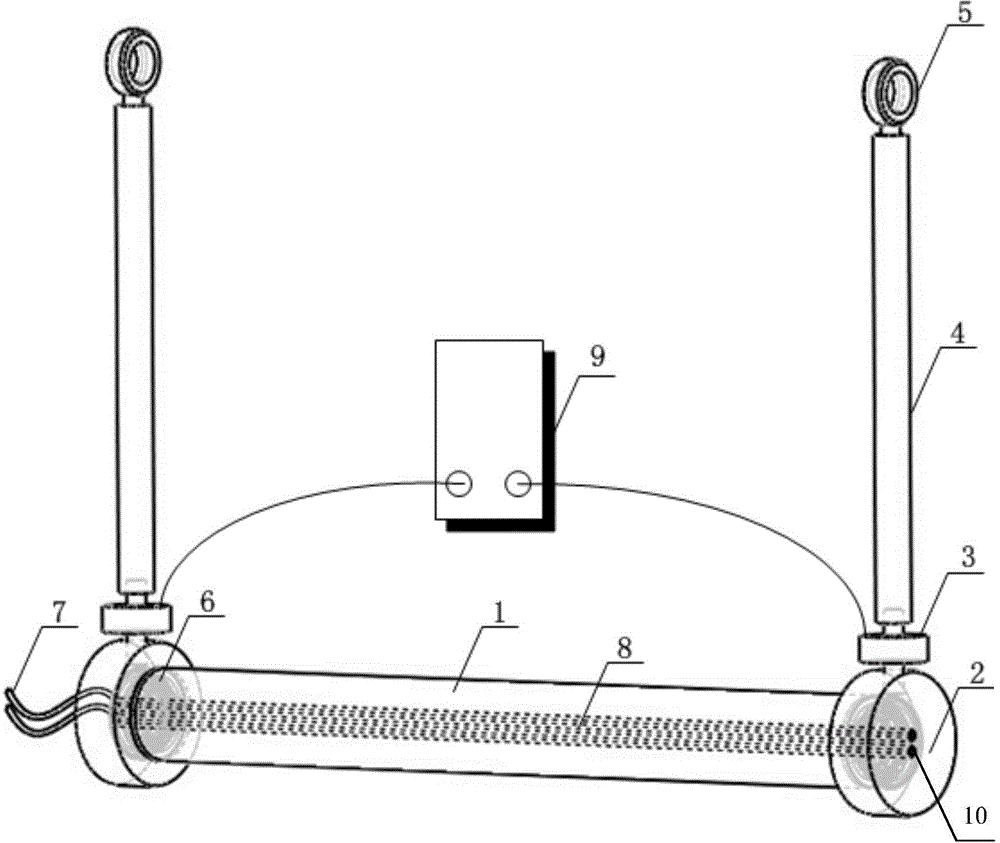

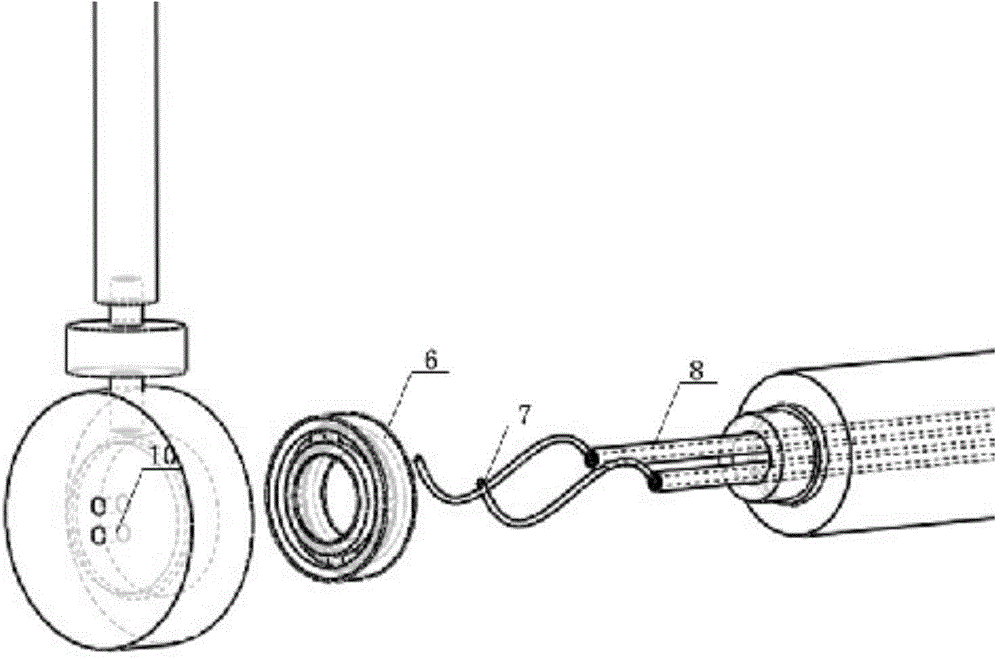

[0019] figure 1 Is a schematic diagram of the structure of the present invention, figure 2 This is a partial exploded view of the present invention. As shown in the figure, a transmission line ice monitoring device based on a rotating reference conductor provided by the present invention at least includes a reference conductor 1, a suspension bracket, and a tension sensor 3. The reference conductor 1 is It is connected to the tension sensor 3 in a rotatable manner, and the tension sensor 3 is fixedly connected to the suspension bracket. The reference conductor 1 is provided with an ice melting unit. In this embodiment, the monitoring data output by the tension sensor is wired or wireless. It can be transmitted to the monitoring center (the monitoring center can be a monitoring station, a substation or a substation command center, etc.), and the monitoring data can also be transmitted to the control unit of the ice melting device of the transmission line through a wired or wirel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com