N-channel field effect transistor resistant to single particle effect and manufacturing method thereof

An anti-single event effect, transistor technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as increasing circuit response time, reduce transient current pulse time and peak value, and improve resistance The effect of reduction in irradiation capacity, charge amount and absorption time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

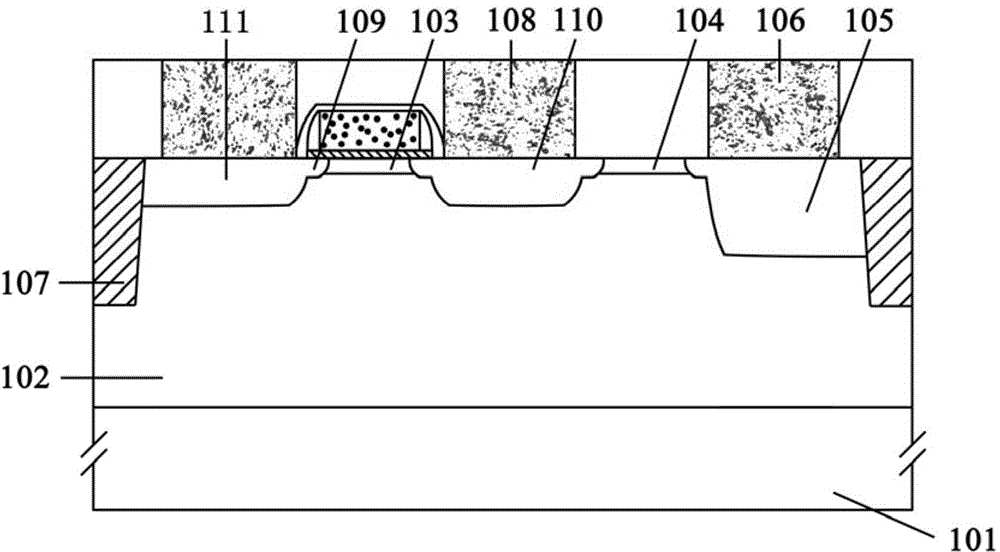

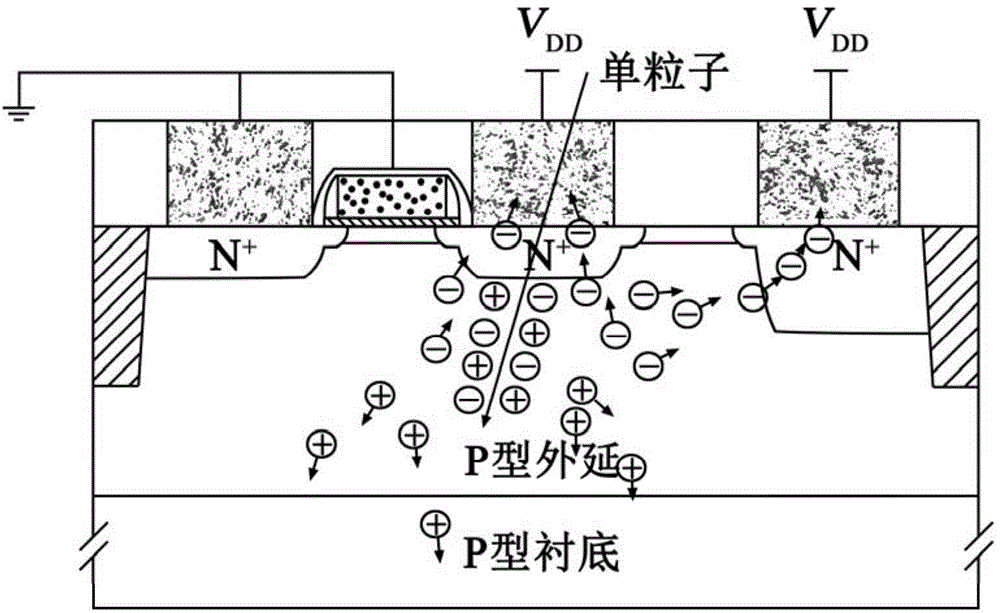

[0016] Such as figure 1 as shown, figure 1 It is a schematic cross-sectional structure diagram of an N-channel field-effect transistor resistant to single event effect of the present invention. 101 is a heavily doped substrate; the epitaxial layer 102 is grown on the substrate 101; on the epitaxial layer 102, the drain region 110 and the source region 111 are located at both ends; the first threshold voltage injection region 103 is located at the drain region 110 and the source region 111, on which is the gate oxide layer and the gate; the drain region electrode 108 is connected to the drain region 110, and connected to the voltage V DD The deep doped drain region 105 is located on the epitaxial layer 102, on the right side of the drain region 110; between the deeply doped drain region 105 and the drain region 110 is the second threshold voltage inj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com