Process for the synthesis of urea comprising a passivation stream at the stripper bottom

A stripping tower and stripping technology, applied in chemical instruments and methods, separation methods, organic chemistry, etc., to achieve easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

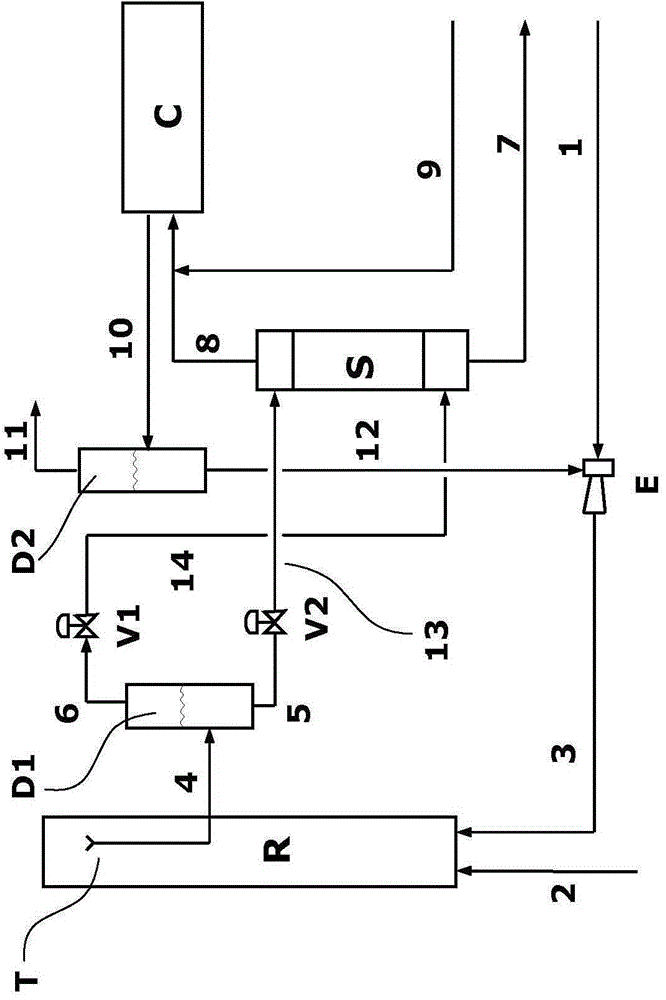

[0105] According to the present invention, the method for realizing urea synthesis is based on figure 1 program operation shown, which would contain CO 2 , NH 3 and an appropriate amount of O as a passivating agent 2 The gas stream of is fed to the bottom (base, base) of the stripping column (S), in addition to the inert products from the gas-liquid separation unit (D1) and traces of water. No further volumes of air or other passivating agents are separately fed to the bottom of the stripper or other parts of the plant. refer to figure 1 The scheme shown in and the nominal (nominal) production of urea of 1,000 kg / h. Impurities present at flow rates below 0.5 kg / h are ignored, such as, for example, hydrogen, helium, metal salts.

[0106] The following products are separately fed to the reactor (R):

[0107] - 730 kg / h of CO as a gas stream through line 2 at 120 °C and 16.3 MPa 2 and 8kg / h of air;

[0108] - 492 kg / h of CO via line 3 as a solution of ammonium carbamate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com