Method for supplementing biogas by virtue of liquefied natural gas (LNG) blended with air

A technology of liquefied natural gas and air blending, which is applied in the fields of gas fuel, petroleum industry, fuel, etc., can solve the problems of inability to supply on demand and reduction of biogas production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

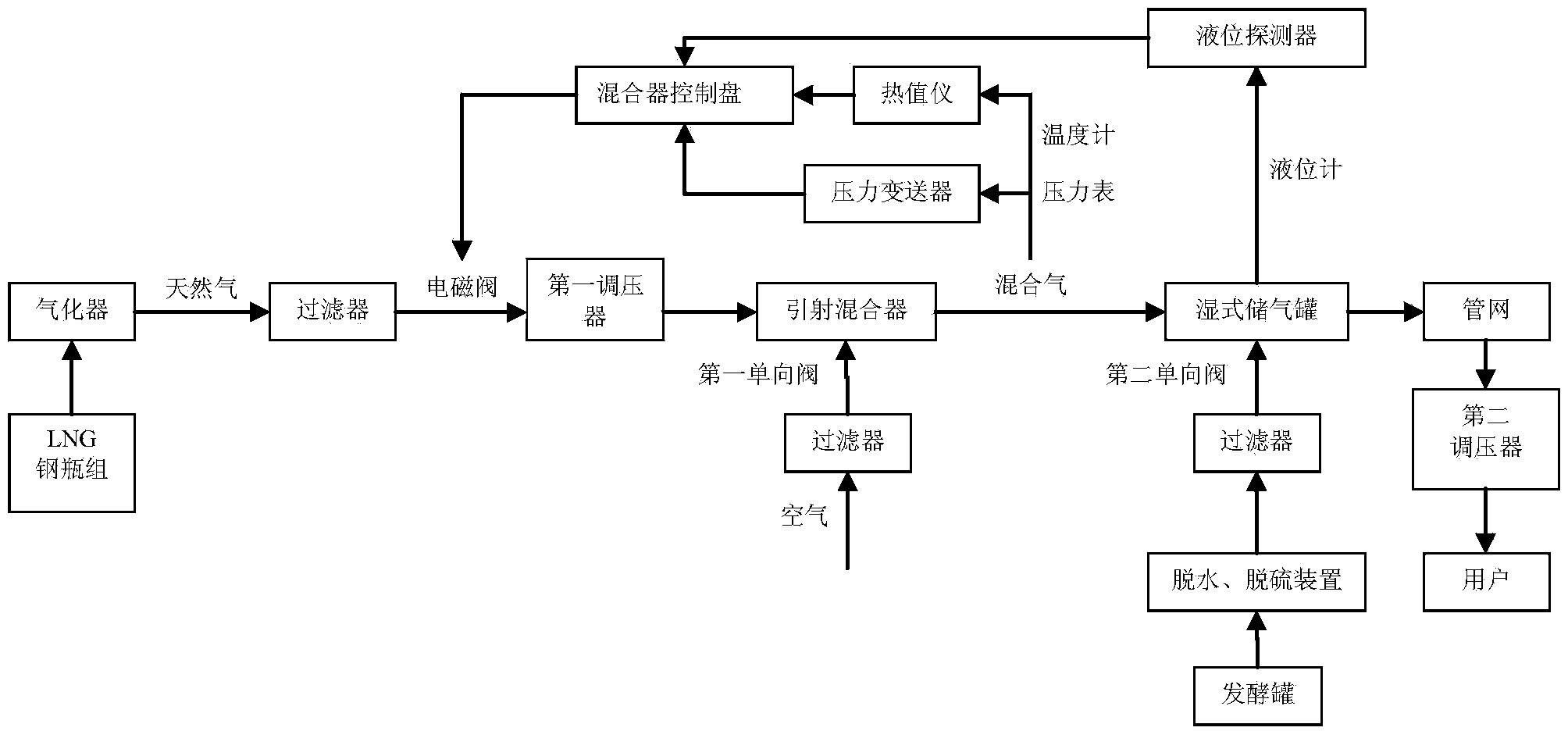

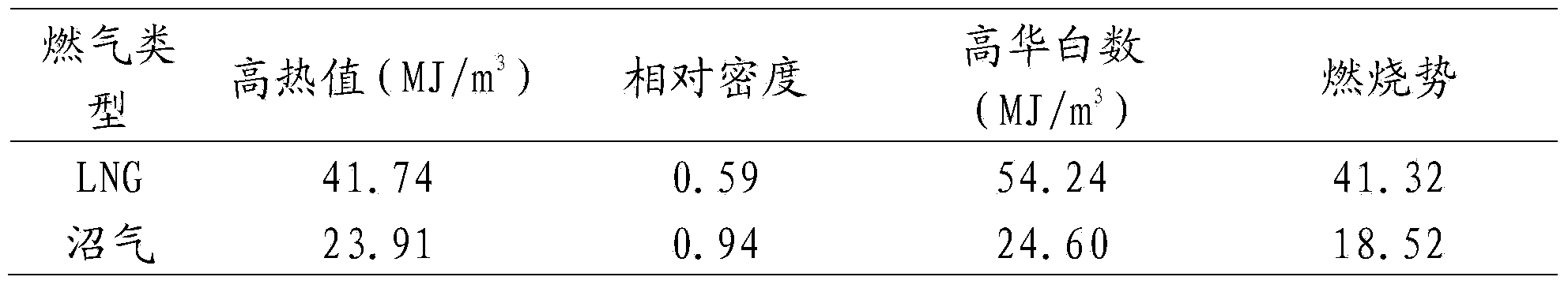

[0022] Example 1 Interchangeability analysis of conventional gas mixed with air and biogas

[0023] Biogas burners are designed with biogas as the reference gas, and when using another gas with different components, the fluctuation of combustion conditions is within the allowable range, then this gas is said to be interchangeable with the reference gas. The fluctuation of gas components must meet the requirements of interchangeability. In my country, the Wobbe number and the variation range of combustion potential are used to judge whether the requirements of interchangeability are met.

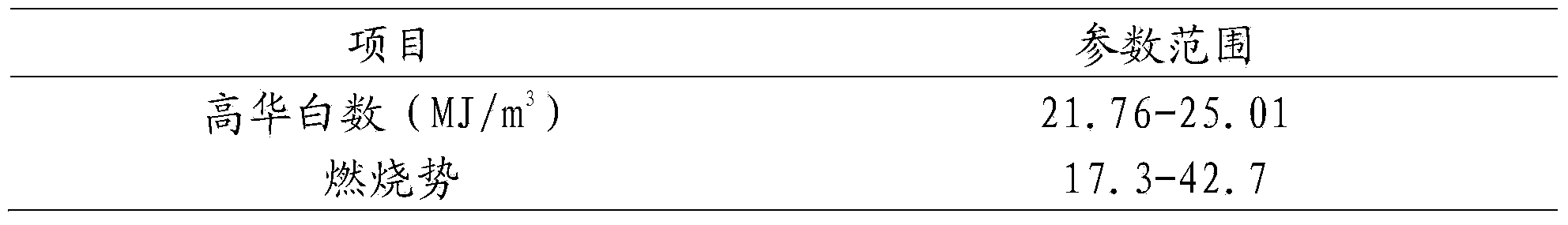

[0024] 1. The nature of the reference gas

[0025] The 6T gas in "Corporate Gas Classification and Basic Characteristics" GBT13611-2006 represents biogas as the reference gas for interchangeability analysis, and this specification stipulates the Wobbe number and combustion potential range of 6T gas, as shown in the following table:

[0026] Table 16T Gas Properties

[0027]

[0028] 2. M...

Embodiment 2

[0069] When the temperature is high in summer, the gas production rate of the fermentation tank is high. The biogas produced is purified by dehydration tower, desulfurizer and filter. Under the pressure, the second one-way valve is opened, and the biogas enters the wet gas storage tank. When the liquid level detector detects that the volume of biogas in the wet gas storage tank is greater than 90% of the volume of the wet gas storage tank, the liquid level signal is sent to the mixer control panel, and the mixer control panel sends an instruction to close the solenoid valve, and the natural gas does not enter Negative pressure is generated in the injection mixer, and the first one-way valve is naturally closed. The biogas in the wet gas storage tank is used as the gas source alone, and it is input into the pipeline network, and after the pressure is adjusted to 2200-3000Pa by the second pressure regulator, it is used by the user.

Embodiment 3

[0071] In spring and autumn, the temperature is low, the gas production rate of the fermentation tank is low, the biogas volume of the wet gas storage tank is insufficient, and when the gas volume in the wet gas storage tank is less than 30% of the total volume, the liquid level detector will send an unlocking signal to the mixing Open the solenoid valve on the gasified natural gas pipeline. The liquefied natural gas in the LNG cylinder group is gasified by the gasifier and enters the filter to be separated into gas phase natural gas and liquid phase natural gas. The gas phase natural gas enters the first gas phase through the opened solenoid valve. After the pressure regulator is adjusted to 0.4MPa, the gas phase natural gas enters the ejector mixer under the pressure, and is ejected at a high speed through a supersonic nozzle, and a negative pressure is formed in the suction chamber, and natural air from the outside is introduced. Natural gas forms a uniform mixed gas output....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com