fe-pt-ag-c-based sputtering target dispersed with c particles and manufacturing method thereof

一种制造方法、溅射靶的技术,应用在溅射靶领域,能够解决异常放电、难以得到高密度烧结体、无法制造出等问题,达到粉粒量降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

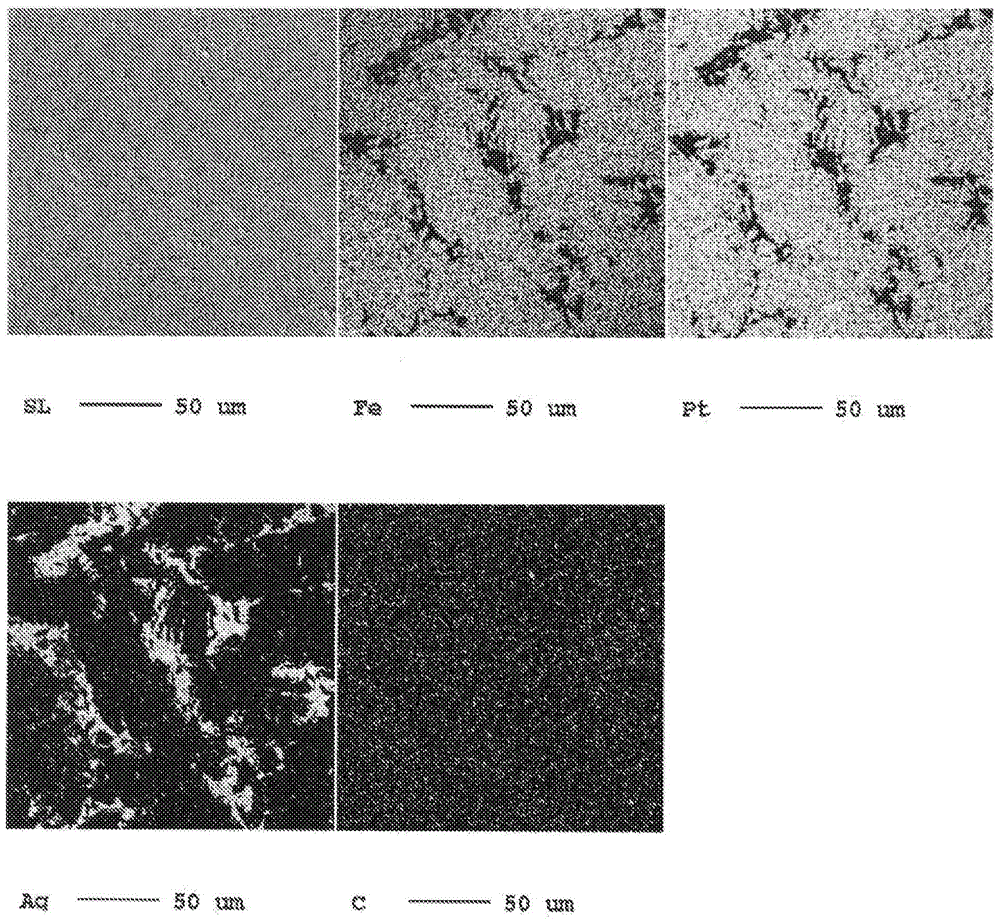

Embodiment 1

[0073] As raw material powders, Fe powder with an average particle diameter of 3 μm, Pt powder with an average particle diameter of 3 μm, Ag powder with an average particle diameter of 2 μm, and C powder with an average particle diameter of 1 μm were prepared. First, Fe powder, Pt powder, and C powder were weighed in a total weight of 3000 g according to the following atomic number ratio.

[0074] Atomic ratio: (Fe 50 -Pt 50 ) 52.94 -C 47.06

[0075] Next, the weighed powder was enclosed in a ball mill jar with a capacity of 10 liters together with zirconia balls as a grinding medium, and rotated for 4 hours to perform mixing and grinding. Then, the powder taken out of the tank is filled into a carbon mold, molded and sintered using a hot press device. The hot pressing conditions were: vacuum atmosphere, heating rate 300° C. / hour, holding temperature 1400° C., holding time 2 hours, and pressurization at 30 MPa from the start of heating to the end of holding. Cool natural...

Embodiment 2

[0086] As raw material powders, Fe powder with an average particle diameter of 3 μm, Pt powder with an average particle diameter of 3 μm, Ag powder with an average particle diameter of 2 μm, and C powder with an average particle diameter of 1 μm were prepared. First, Fe powder, Pt powder, and C powder were weighed in a total weight of 3000 g according to the following atomic number ratio.

[0087] Atomic ratio: (Fe 50 -Pt 50 ) 56.25 -C 43.75

[0088] Next, the weighed powder was enclosed in a ball mill jar with a capacity of 10 liters together with zirconia balls as a grinding medium, and rotated for 4 hours to perform mixing and grinding. Then, the powder taken out of the tank is filled into a carbon mold, and molded and sintered using a hot press device. The hot pressing conditions were: vacuum atmosphere, heating rate 300° C. / hour, holding temperature 1400° C., holding time 2 hours, and pressurization at 30 MPa from the start of heating to the end of holding. Cool nat...

Embodiment 3

[0105] As raw material powders, Fe powder with an average particle diameter of 3 μm, Pt powder with an average particle diameter of 3 μm, Ag powder with an average particle diameter of 2 μm, and C powder with an average particle diameter of 1 μm were prepared. First, Fe powder, Pt powder, and C powder were weighed in a total weight of 3000 g according to the following atomic number ratio.

[0106] Atomic ratio: (Fe 65 -Pt 35 ) 42.11 -C 57.89

[0107] Next, the weighed powder was enclosed in a 10-liter ball mill jar together with zirconia balls as a grinding medium, and rotated for 4 hours to perform mixing and grinding. Then, the powder taken out of the tank is filled into a carbon mold, and molded and sintered using a hot press device. The hot pressing conditions were: vacuum atmosphere, heating rate 300° C. / hour, holding temperature 1400° C., holding time 2 hours, and pressurization at 30 MPa from the start of heating to the end of holding. Cool naturally in the chambe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com