Improved optical systems and LED luminaires

A technology of LED lamps and optical systems, applied in the field of lenses, can solve the problems of no reflective surface design and no luminous effect of the lens, and achieve the effects of good reflection effect, good aggregation and reflection effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

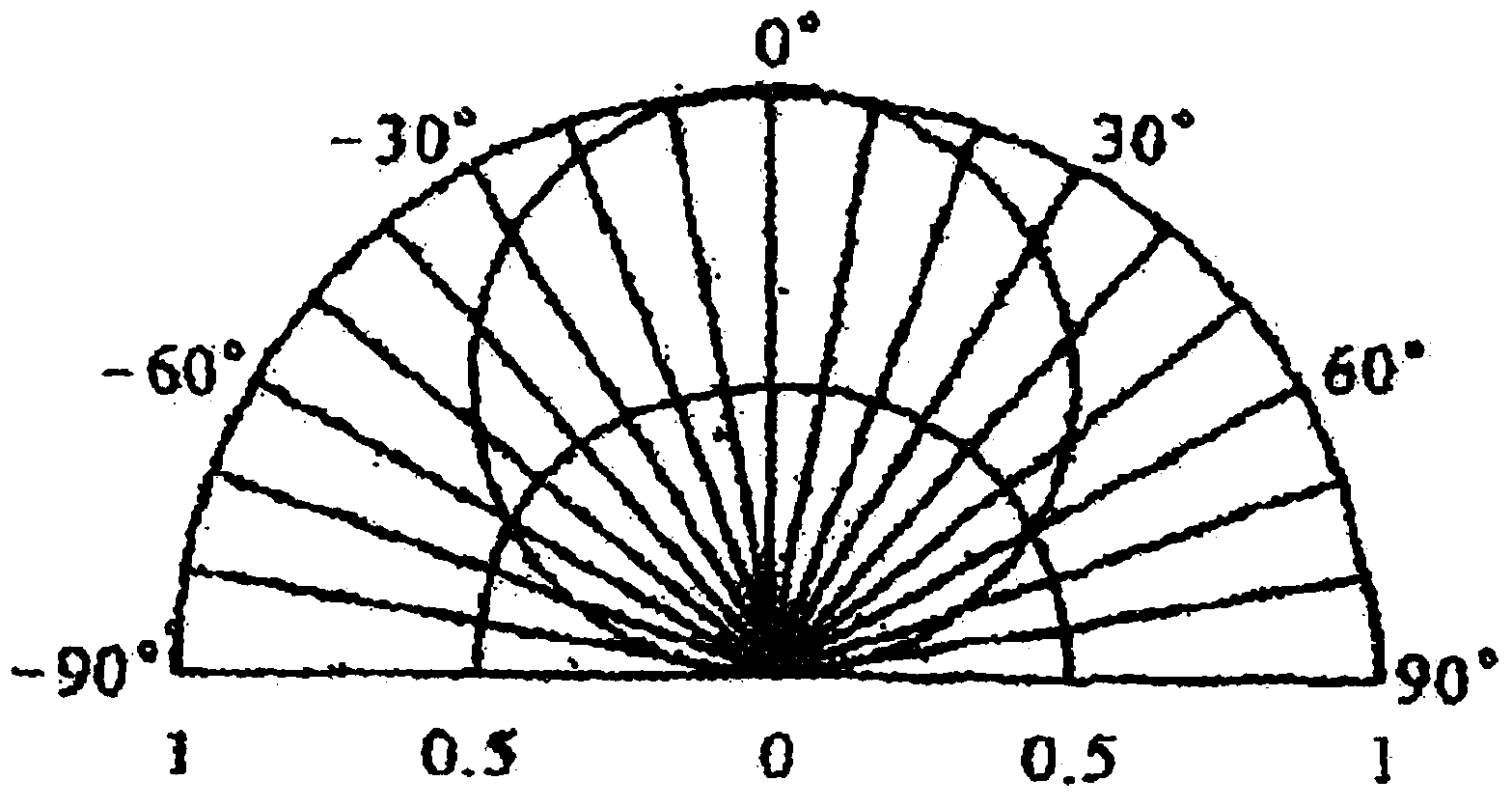

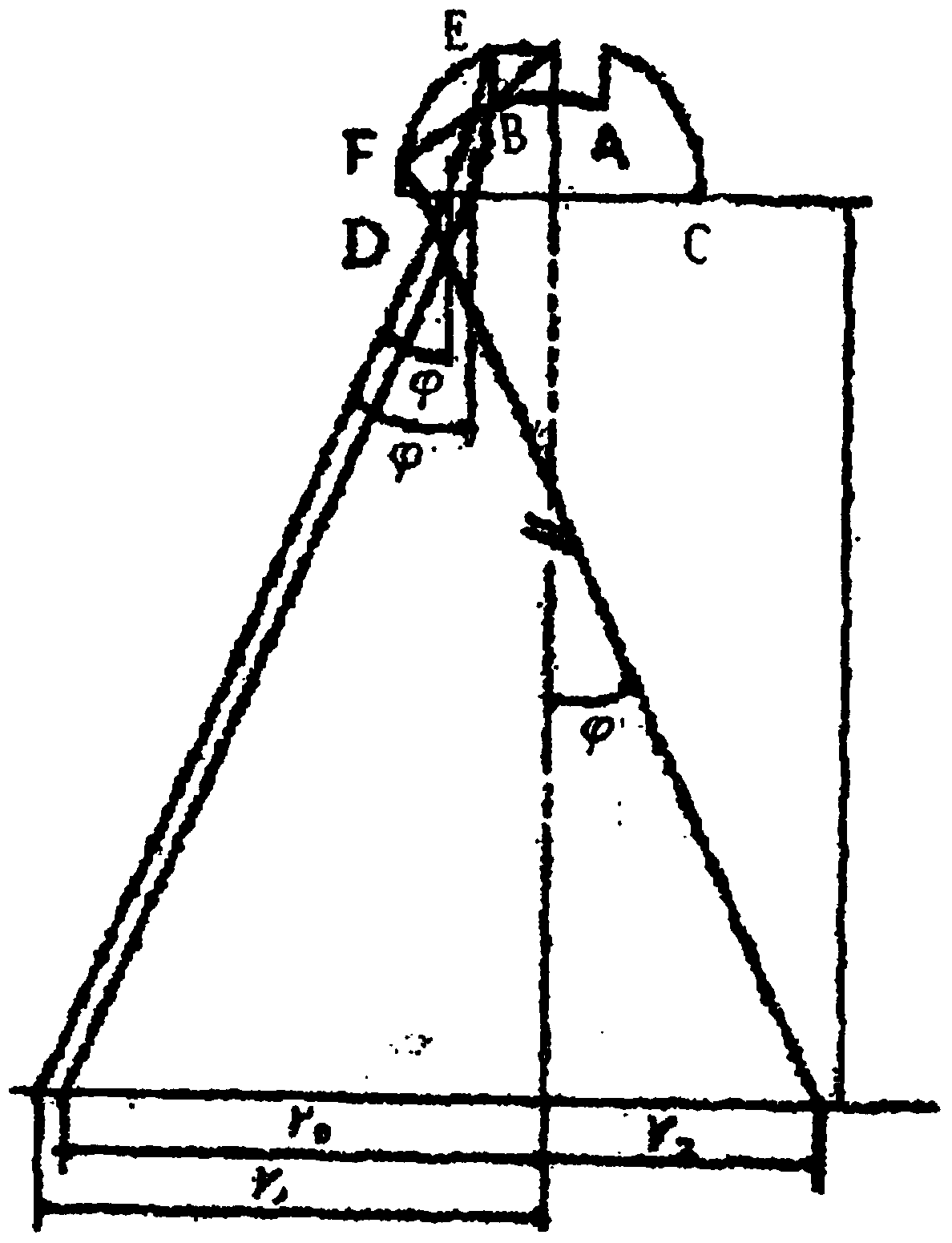

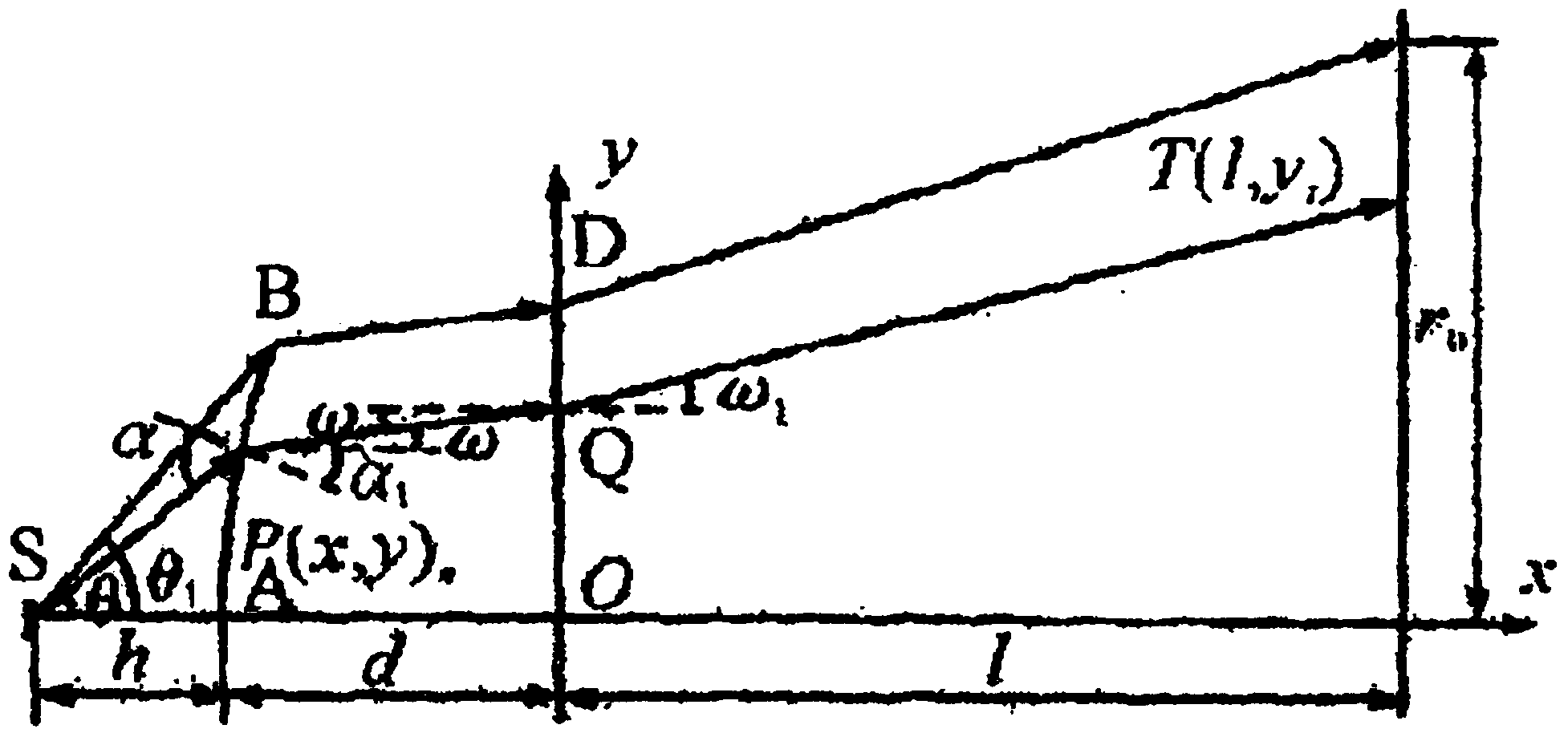

[0107] Such as Figure 5 In the shown embodiment 1, a 1mmx1mm LED chip is used as the light source, and its luminous flux is 1351m. The light source forms a divergence angle of 65° after passing through the lens. The lens material is polymethyl methacrylate (PMMA), and it is a multi-segment reflective surface, and the detailed dimensions of the multi-segment reflective surface design are as follows: Figure 5 shown. The multi-segment reflective surface 3 designed according to the method described above includes two arc line segments, namely, the curved reflective surface EF and the curved reflective surface FG. Each arc segment can also be designed as a multi-segment arc. Simulated light maps and simulated data can be obtained using the software program TracePro, such as Image 6 with Figure 7 shown.

Embodiment 2

[0109] Such as Figure 8 with Figure 9 In the shown embodiment 2, the total reflection surface lens is integrally molded with a translucent material. The inside of the cone opening is also solid and translucent. The cylindrical first refraction groove 1 is located inside the opening of the cone, and its central axis overlaps with the central axis of the cone. That is, the first refraction groove 1 is just arranged in the middle of the opening of the cone. The cylindrical second refraction groove 2 is arranged on the back of the reflective surface lens. It overlaps the centerline of the first refractive groove, however, they are not connected to each other. The multi-segmented surface 3 located on the outer surface of the reflective surface lens is formed by reflective surfaces 31 , 32 and 33 . Along the direction from the first refraction groove 1 to the second refraction groove 2, the radii of these sequentially connected reflective surfaces gradually increase. Meanwhi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com