Ultra-micro peony flower powder as well as preparation method and application thereof

A technology of superfine powder and peony flower, applied in the application, food preparation, pharmaceutical formulation and other directions, can solve the problems of waste, waste of precious resources, etc., and achieve the effects of stabilizing blood pressure, improving human immunity, and regulating blood lipids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

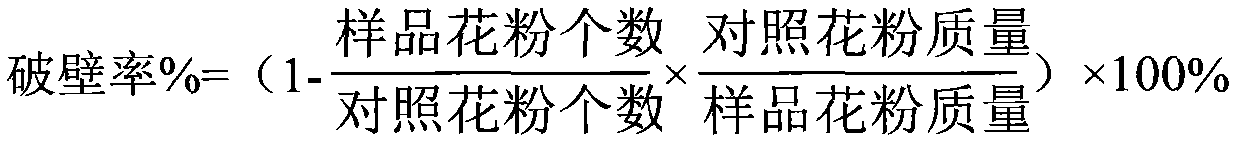

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 peony petal pretreatment

[0035] Step 1. Picking raw materials

[0036] From 6 to 10 o'clock in the morning and after 4 o'clock in the afternoon, pick the phoenix peony flowers that are half-opened to full bloom in the field, with intact flowers, fresh and tender, and disease-free. Place the stamens and petals separately, and remove foreign objects.

[0037] Step two, finish

[0038] The petals were killed at 140°C for 3 minutes.

[0039] Step 3. Vacuum drying

[0040] The petals are placed in a vacuum drying box, the vacuum pressure in the box is adjusted to 0.92 atmospheres, the temperature is 110° C., and the time is 1 hour, so that the water content is lower than 5%.

Embodiment 2

[0041] Embodiment 2 peony petal pretreatment

[0042] Step 1. Picking raw materials

[0043] From 6 to 10 o'clock in the morning and after 4 o'clock in the afternoon, pick the purple-spotted peonies that are half-bloomed to full-bloomed in the field, with intact flowers, fresh and tender, and disease-free, and place the stamens and petals separately, and remove foreign objects.

[0044] Step two, finish

[0045] The petals were killed at 110°C for 5 minutes.

[0046] Step 3. Vacuum drying

[0047] The petals are placed in a vacuum drying box, the vacuum pressure in the box is controlled to standard atmospheric pressure, the temperature is 100° C., and the time is 1.5 hours, so that the water content is lower than 5%.

Embodiment 3

[0048] Embodiment 3 peony petal pretreatment

[0049] Step 1. Picking raw materials

[0050] From 6 to 10 o'clock in the morning and after 4 o'clock in the afternoon, pick the purple-spotted peonies that are half-bloomed to full-bloomed in the field, with intact flowers, fresh and tender, and disease-free, and place the stamens and petals separately, and remove foreign objects.

[0051] Step two, finish

[0052] The petals were killed at 140°C for 3 minutes.

[0053] Step three, hot air drying

[0054] Place the petals in a hot air dryer at a temperature of 90° C. for 2 hours to make the water content lower than 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com