Preparation method of instant chinquapin powder

An instant and instant technology, which is applied in the field of preparation of instant instant powder, can solve problems such as unsatisfactory solubility and dispersibility, agglomeration of powder, and unsatisfactory products, so as to improve solubility, The solution is uniform and stable, and the taste is sweet and delicate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Selection of fresh fruit: the chestnut fruit for processing should be fresh and plump, with a shiny shell, no damage, moth and mildew, and the diameter of the chestnut fruit should be controlled at 15-22mm;

[0033] (2) Shelling: Make a slit on the shell of the pumpkin selected in step (1), then place it in a jacketed pot with a water temperature of 65°C and cook for 1.5 minutes. Then fish out the chestnut from the water, and after it cools down to room temperature, peel off the shell and underwear by hand to obtain the chestnut kernel;

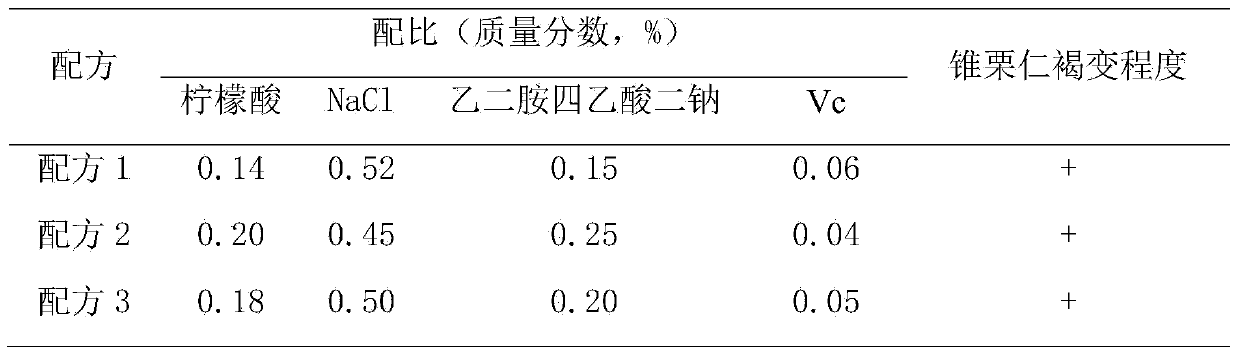

[0034] (3) Blanching and color protection: Boil the chestnut kernels in boiling water for 2 minutes, then take them out, inspect carefully, remove the remaining underwear, and remove bad fruits. Then put the chestnut kernels in the compound color protecting solution to soak for color protection, the temperature of the color protecting solution is 65°C, and the soaking time is 25 minutes. There are 3 formulas of compound color prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com