All-fiber-texture large-size double-flange fan main shaft forging method

A double-flange, full-fiber technology, applied in the field of forging, can solve the problems of poor impact resistance at the root of the flange, easy deformation of the flange, and easy vibration during operation, so as to eliminate the poor impact resistance and meet the design requirements. , the effect of considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] The forging process of the 45A large double-flange motor spindle includes the following steps:

[0030] a. According to the quality control requirements of raw materials, 45A steel ingots smelted by electric arc furnace + external refining + vacuum degassing are selected as raw materials, which conform to Q / HWG-QW07009-2000, and the content of harmful elements and gases in the chemical composition is controlled to be S≤0.020 , P≤0.015, H≤2ppm, O≤30ppm, N≤65ppm, Cu≤0.20, to ensure the purity and grain refinement of steel;

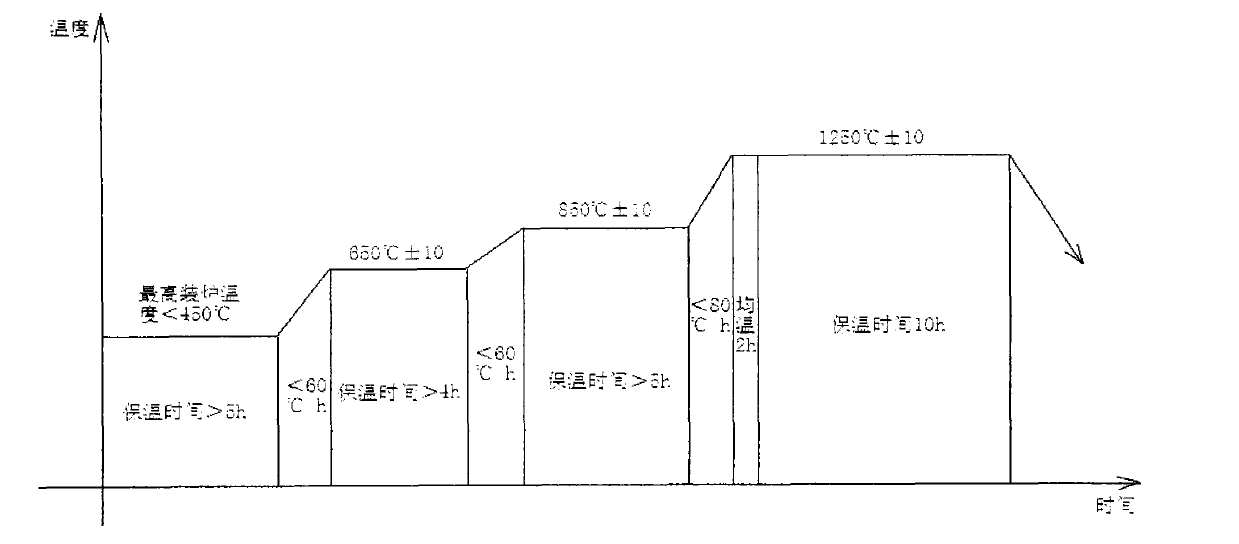

[0031] b. If figure 1 As shown, put the ingot into a heating furnace with a temperature lower than 450°C for preheating and heat preservation for 5 hours, then raise the temperature at 60°C per hour to 650°C for 4 hours, and then heat it at 60°C per hour to 850°C for 5 hours. Finally, the temperature is raised from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com