Sludge drying system and method

A sludge drying and dryer technology, which is applied in dewatering/drying/concentrating sludge treatment and other directions, can solve the problems of low temperature corrosion of conveying pipelines and equipment, high operation and maintenance costs, and high equipment failure rate, and achieve extended operating life. , The effect of reducing operation and maintenance costs and operating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment.

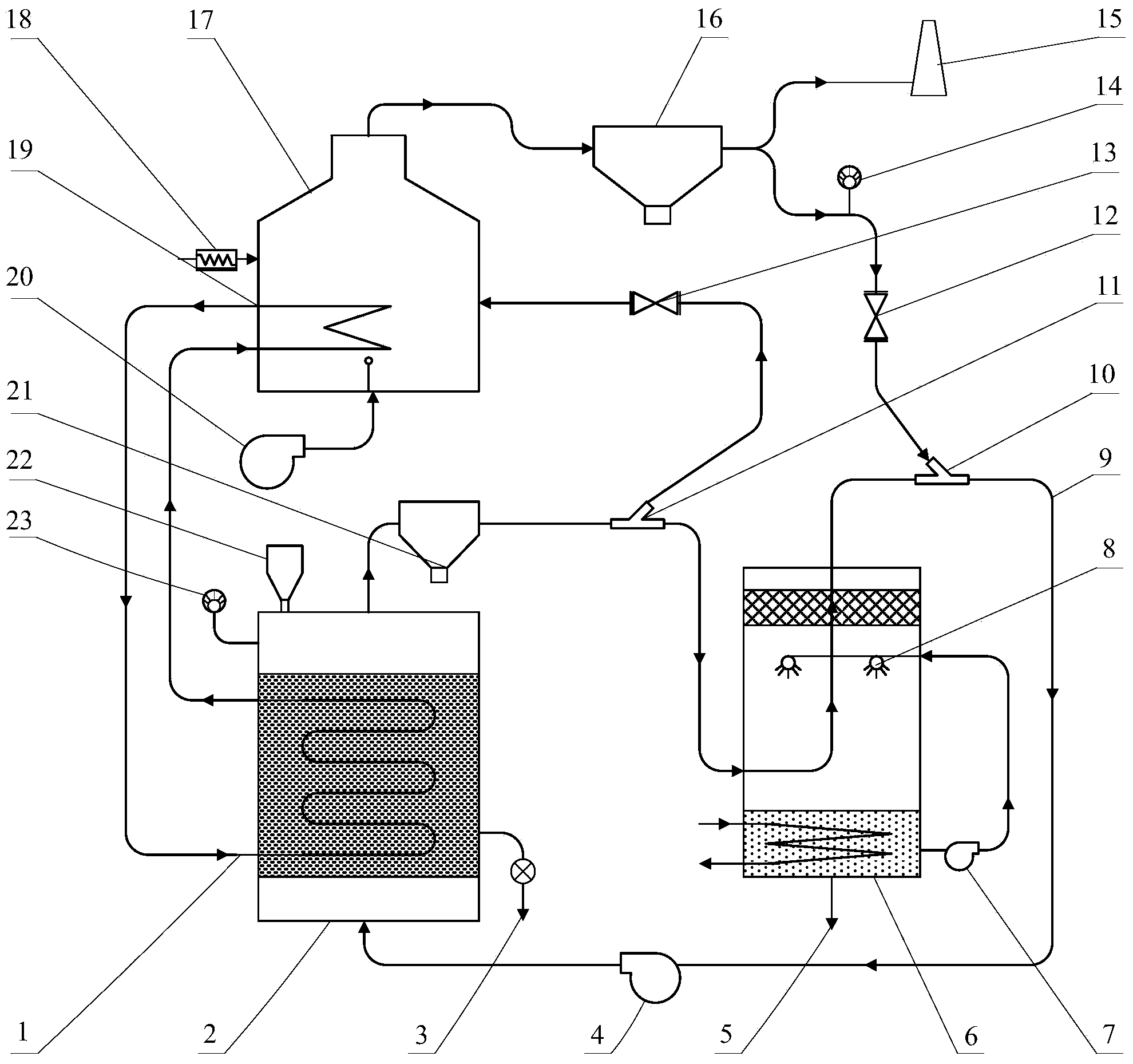

[0029] see figure 1 , a sludge drying system, including a boiler 17, the exhaust outlet of the boiler 17 is connected to the chimney 15 through a pipeline, and the other is connected to the first air inlet of the No. 1 mixer 10 with a three-way structure, and the No. 1 mixer The exhaust port of 10 is connected to the air inlet of the fluidized bed dryer 2 through the fluidized air duct 9, and the fluidized air duct 9 is provided with a fluidizing fan 4, and the exhaust port of the fluidized bed dryer 2 is connected to three The inlet of the No. 2 mixer 11 of the open structure, the first outlet of the No. 2 mixer 11 is connected to the inlet of the condenser 6, and the gas outlet of the condenser 6 is connected to the second inlet of the No. 1 mixer 10. mouth, the condenser 6 is provided with a demister, a spray head and a sump in sequence from top to bottom. The cooling water is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com