Formula for producing construction template from PVC plastic

A technology for building templates and plastics, which is applied in the field of formulas for producing building templates using PVC plastics. It can solve problems such as poor fire resistance, poor impact resistance, and easy aging, and achieve the effects of light weight, improved service life, and convenient building construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

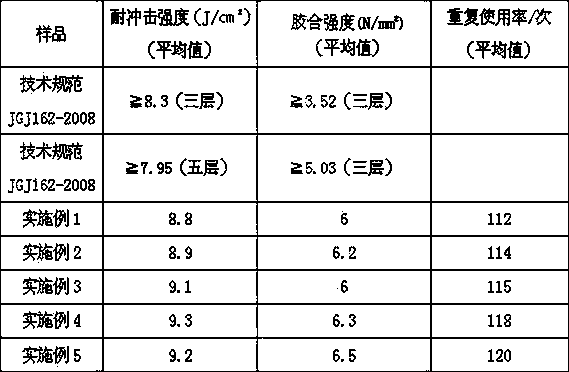

Examples

Embodiment 1

[0024] A formula for producing building templates using PVC plastics, the composition of which is as follows: 5 parts of foaming regulator, 0.2 parts of AC foaming agent, 0.5 parts of white foaming agent, 5 parts of modifier, 1 part of benzimidazolone pigment 1 part, aromatic amine curing agent 1 part, magnesium hydroxide 0.4 part, polyborosiloxane 0.2 part, tribasic lead sulfate 0.1 part, wood flour 20 parts, pvc plastic 100 parts, light calcium 60 parts.

[0025] Its preparation method is as follows:

[0026] (1) Melt and extrude the waste plastic through a plastic extruder, then cool it, and cut it into plastic particles of uniform size through a pelletizer;

[0027] (2) Mix the plastic granules and other raw materials obtained in step (1) in a PVC high and low temperature mixer at 120-125°C for 20-30 minutes, then cold mix at 15-25°C for 10-15 minutes to obtain a uniform the mixture;

[0028] (3) Extrude the mixture from the machine head after kneading by a plastic extru...

example example 2

[0030] A formula for producing building templates using PVC plastics, the composition of which is as follows: 10 parts of foaming regulator, 0.5 parts of AC foaming agent, 0.8 parts of white foaming agent, 10 parts of modifier, 5 parts of benzimidazolone pigment 1.5 parts, aromatic amine curing agent 1.5 parts, magnesium hydroxide 0.6 parts, polyborosiloxane 0.3 parts, tribasic lead sulfate 0.25 parts, wood flour 30 parts, pvc plastic 100 parts, light calcium 80 parts.

[0031] The preparation method is the same as in Example 1.

Embodiment 3

[0033] A formula for producing building templates using PVC plastics, the composition of which is as follows: 6 parts of foaming regulator, 0.25 parts of AC foaming agent, 0.55 parts of white foaming agent, 8 parts of modifier, 3 parts of benzimidazolone pigment 1.4 parts, aromatic amine curing agent 1.4 parts, magnesium hydroxide 0.6 parts, polyborosiloxane 0.2 parts, tribasic lead sulfate 0.1 parts, wood flour 25 parts, pvc plastic 100 parts, light calcium 80 parts.

[0034] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com