A kind of water-based antirust agent and preparation method thereof

A technology of water-based antirust agent and surfactant, which is applied in the field of water-based antirust agent and its preparation, can solve the problems of increasing labor production intensity of workers, environmental pollution of waste water and waste, and high corrosiveness of finished products, so as to improve the efficiency before painting , Simplified treatment process, strong adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The present invention will be further described in detail below in conjunction with the examples.

Embodiment

[0027] Embodiment: as follows

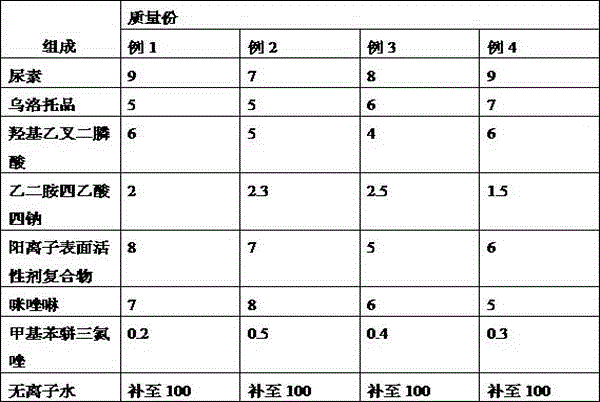

[0028]

[0029] Explanation: The cationic surfactant compound of the present invention can be a compound of fatty ammonium and quaternary ammonium salt cationic surfactants. The components of the present invention are commercially available.

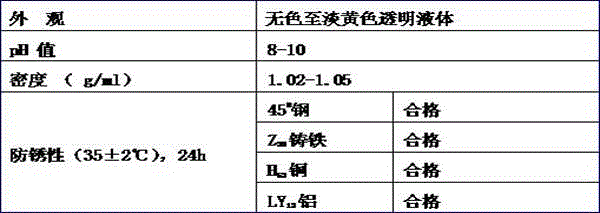

[0030] The above-mentioned embodiments of the present invention can be prepared by the following method: at normal temperature, urea, urotropine, i.e. hexamethylenetetramine, and tetrasodium edetate are dissolved in water to form a solution; then Cationic surfactant complex, imidazoline, and tolyltriazole are dissolved in water to form a solution; after mixing the above two solutions, finally add hydroxyethylidene diphosphonic acid to the above solution, and stir well to get the product The product of the present invention is a transparent liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com