Polymer-material water conveying system and manufacturing and mounting method thereof

A polymer material and water delivery system technology, applied in the polymer material water delivery system and its manufacturing and installation fields, can solve the problems of significant differences in winter and summer temperature, light environment, easy aging, poor durability, etc., to shorten the construction period, resist Strong seismic performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

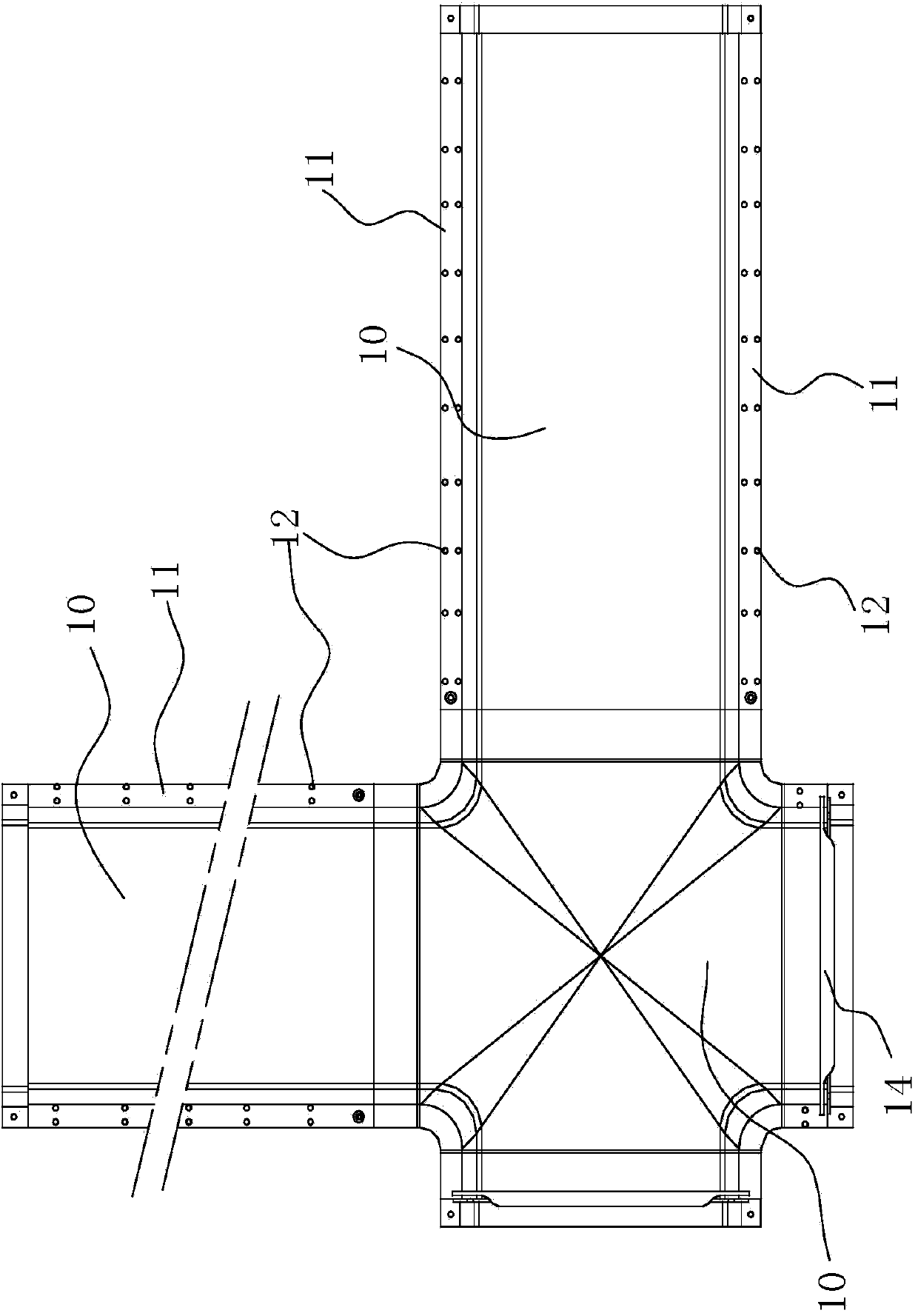

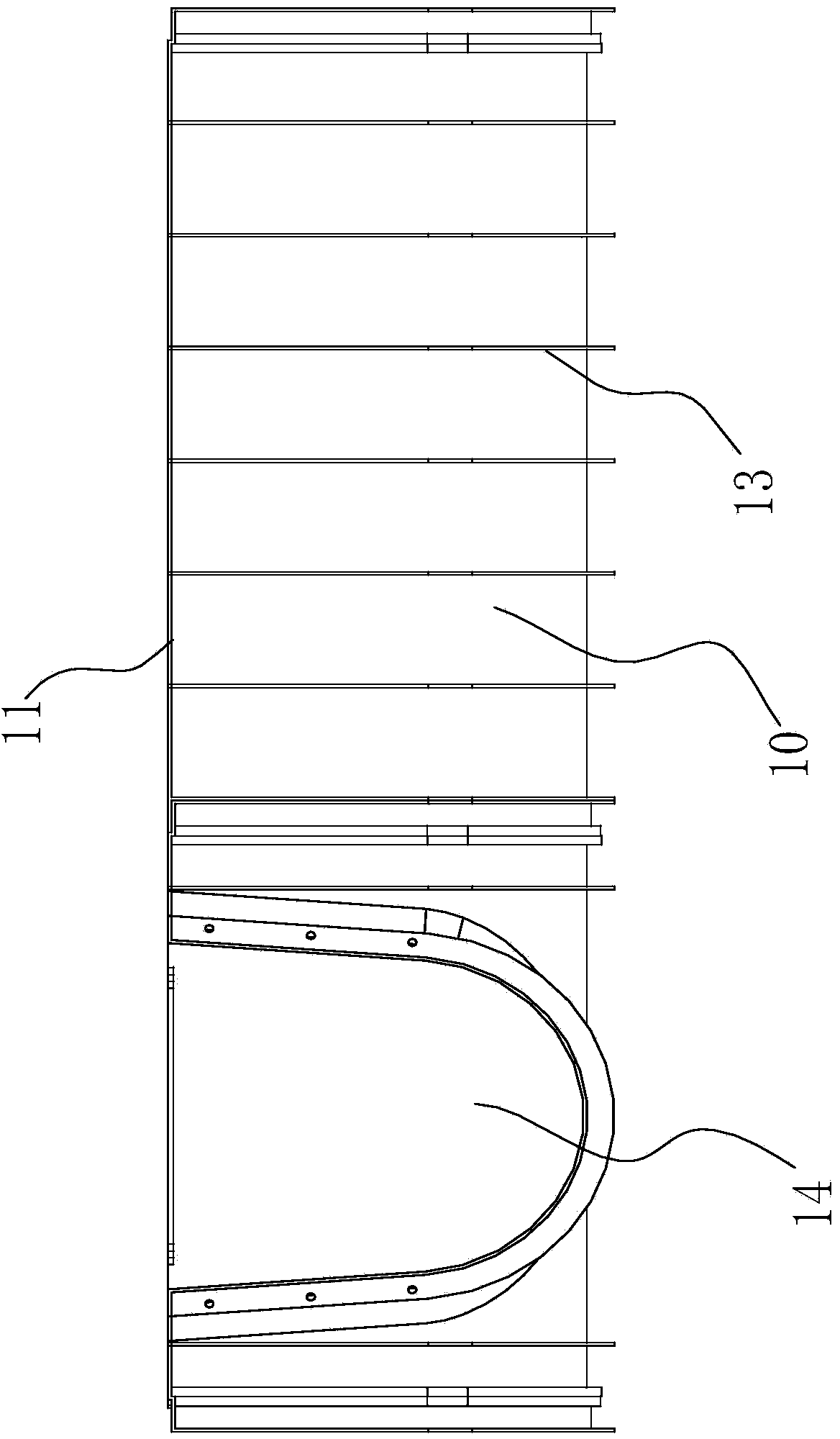

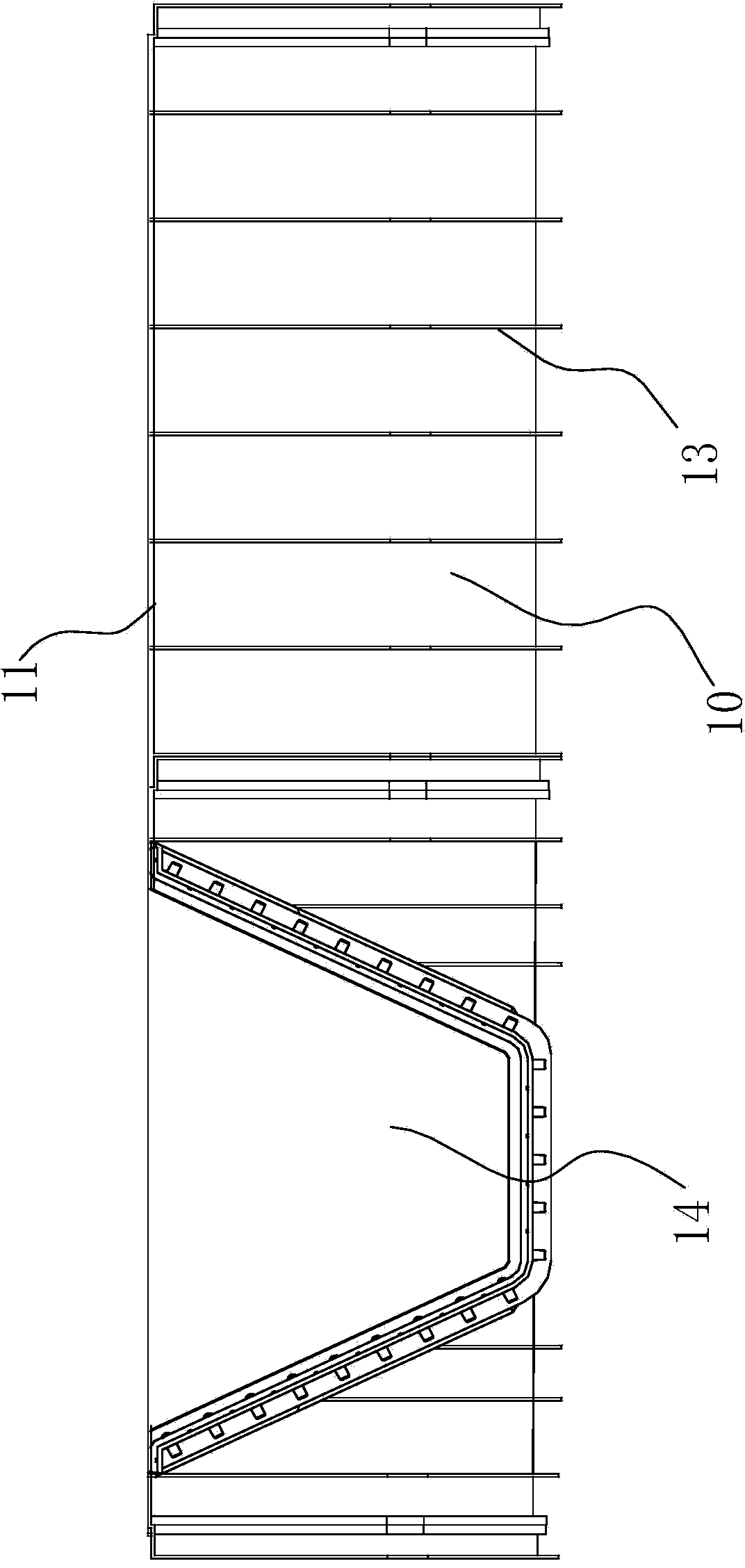

[0027] Such as Figures 1 to 3 As shown, the polymer material water delivery system is composed of a plurality of monomers 10 connected together, usually in an end-to-end manner. Each monomer 10 is in the shape of a tank shell, and a reinforcing rib 13 is integrally processed on the monomer 10 , and the reinforcing rib 13 is arranged on the outer surface of the monomer 10 along the direction of the width and height of the groove. Such as figure 2 As shown, the length direction of the monomer 10 is the left and right direction of the drawing, the width and height direction of the monomer is the direction perpendicular to the paper surface and the direction of the paper surface, and the reinforcing rib 13 is along the direction perpendicular to the paper surface and the paper surface. Arranged on the outer wall of the monomer 10. Such ribs 13 can not only strengthen the structural strength of the monomer 10, but also allow the monomer 10 to have room for deformation in the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com