All-shearing type magneto-rheological damper

A magneto-rheological damper and pure shear technology, applied in vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of low utilization rate of magnetorheological fluid, limited range of controllable damping force and controllable damping ratio, etc. , to achieve the effects of increased controllable damping ratio range, easy protection, and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

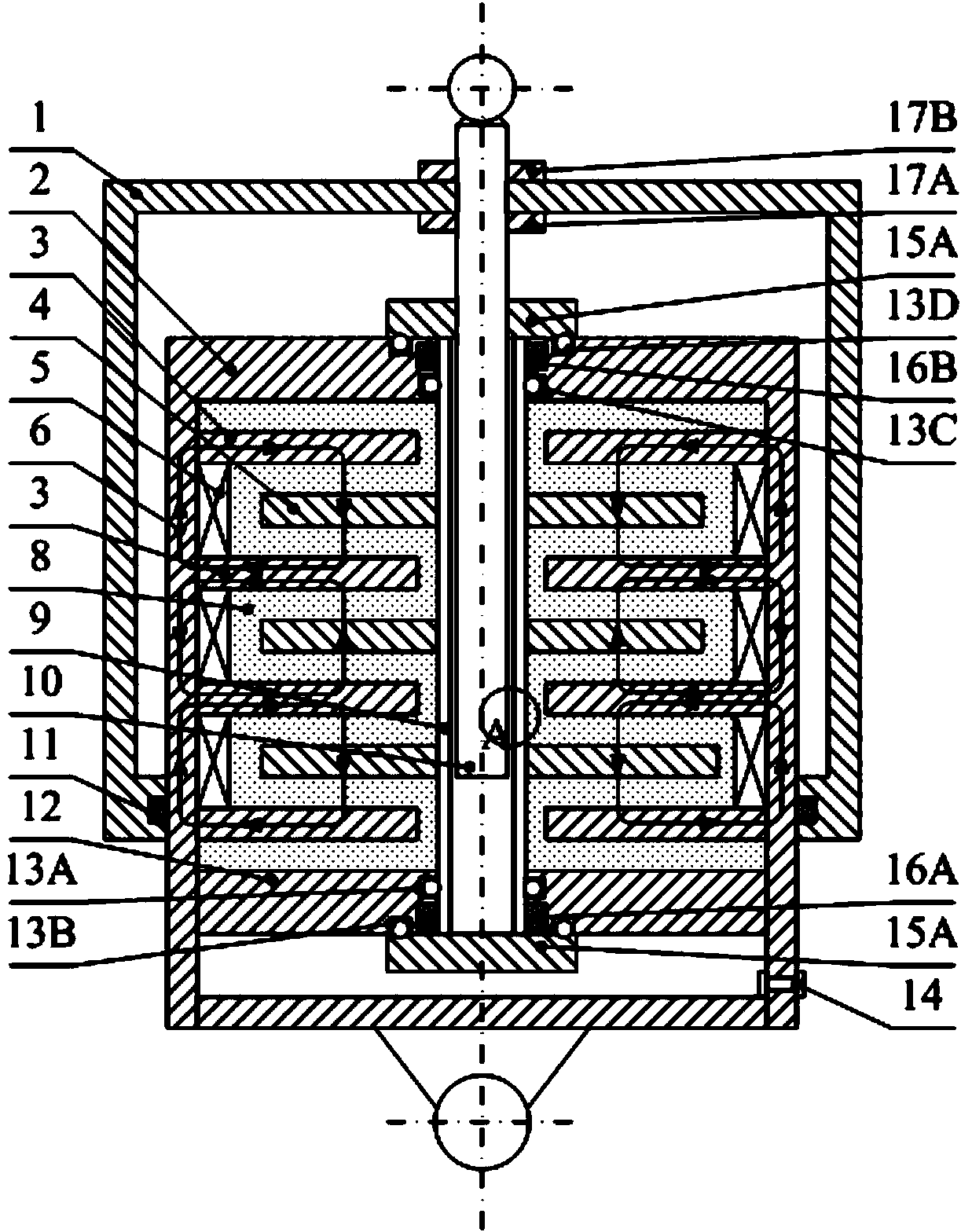

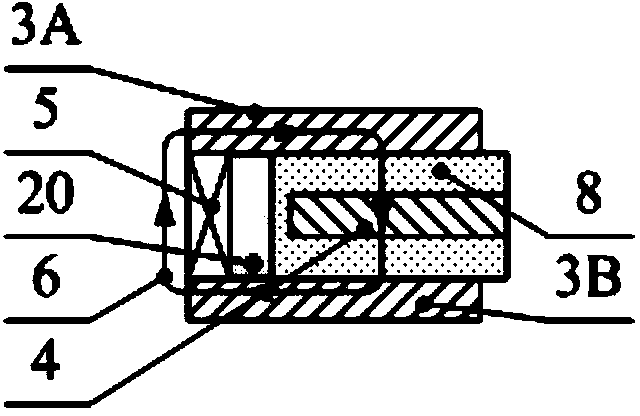

[0031] See Figure 1 and figure 2 , the pure shear magnetorheological damper in this embodiment includes an outer cylinder body 1, an inner cylinder body 2 and a ball screw nut 9 with a shear disc 4 fixed, the outer cylinder body 1 and the inner cylinder body 2 are the same Axis settings;

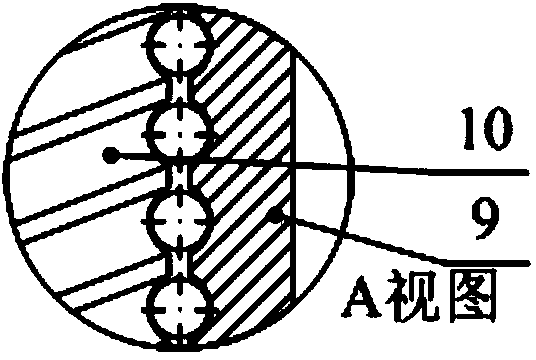

[0032] Figure 1 and figure 2 and image 3 As shown, a ball screw pair is provided, as the screw shaft 10 of the piston rod, one end of which is fixed at the center of the upper end cover of the outer cylinder body 1, and the screw shaft 10 can be compressed into or restored to exit the inner cylinder body 2. The inner side wall of the cylinder body 2 is fixedly provided with an electromagnetic coil 5 and a shearing ring 3 corresponding to the shear disc 4; in the inner cylinder body 2, the inner side wall of the inner cylinder body 2 and the ball screw nut 10 together constitute a closed cavity, which is filled with magnetorheological fluid 8, and the ball screw nut 9 threaded with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com