Method and device for testing content of easily-volatile matters in explosive

A technology of volatile content and explosives, applied in the field of instrument analysis, can solve problems such as affecting the accuracy of experimental results, unable to completely remove volatile substances, etc., to achieve accurate thermal decomposition rate calculation and decomposition kinetic analysis results, accuracy guarantee, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

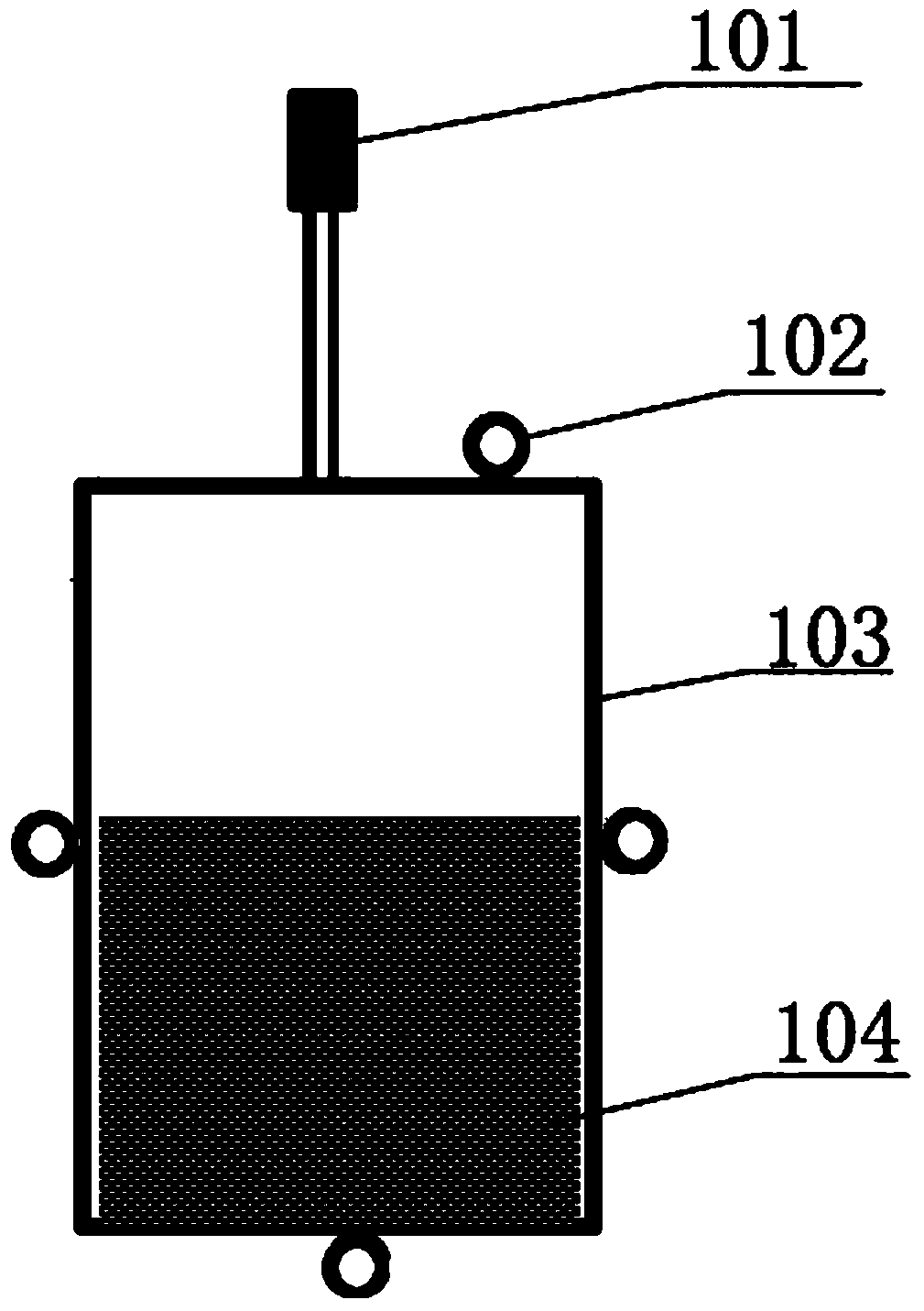

Embodiment 1

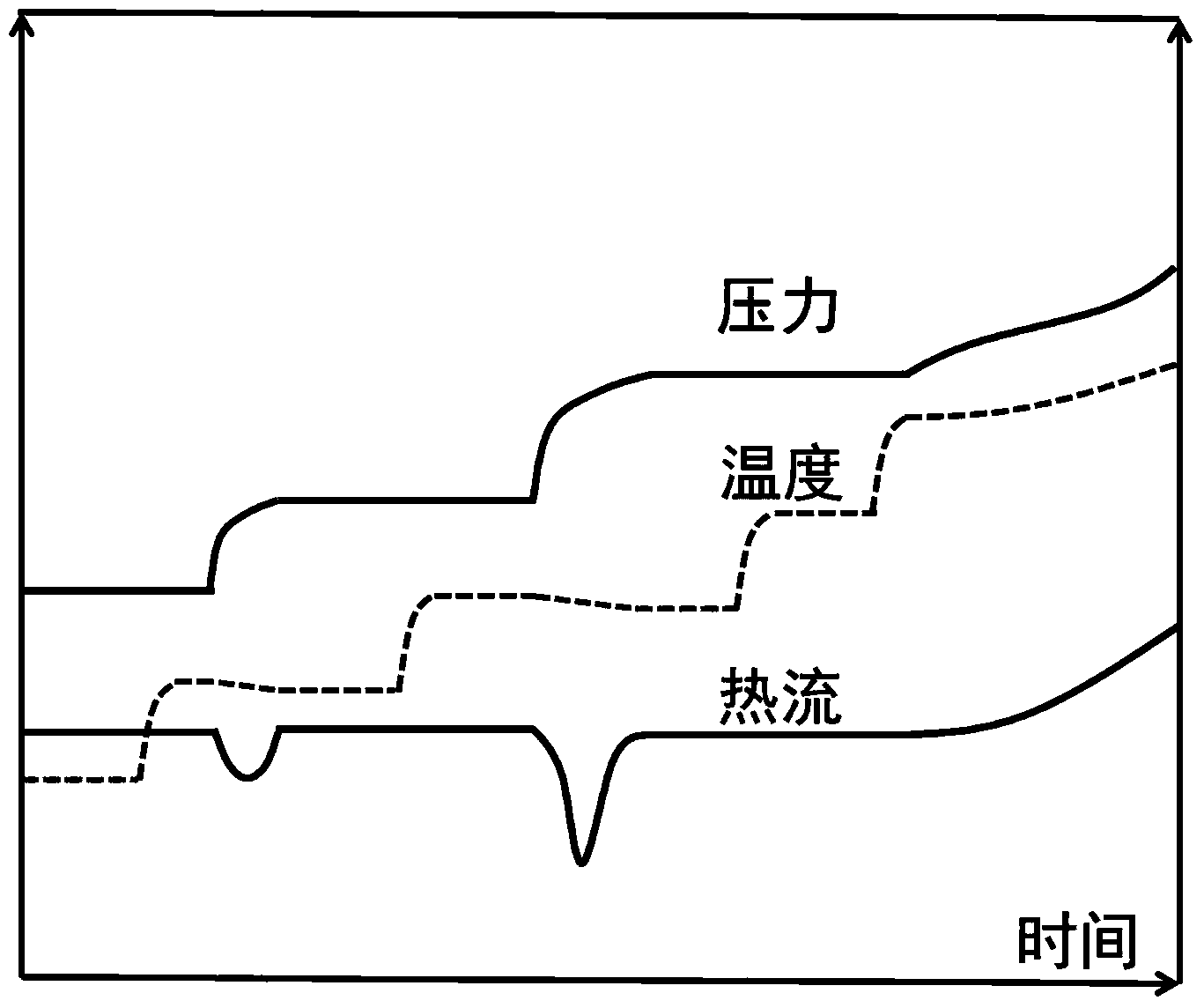

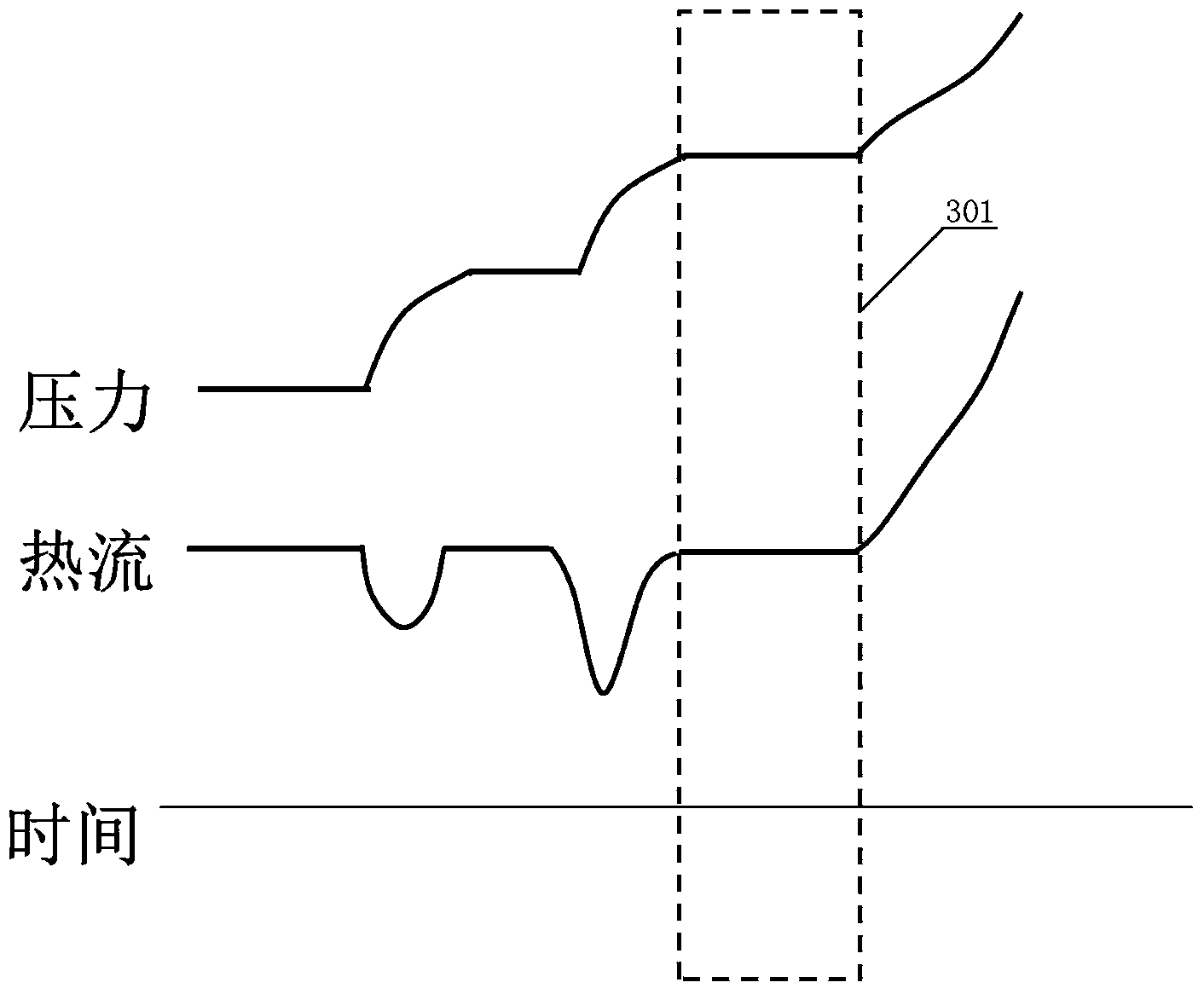

[0045] Add 1g of HMX-based PBX explosives to the sample cell of the device for measuring the content of volatiles in explosives (hereinafter referred to as the improved microcalorimeter), vacuumize the sample cell, and set The initial temperature is 20°C, the waiting time is 5min, the constant temperature time is 30min, the temperature rise step is 1°C, the reaction judgment sensitivity is -0.005°C / min, and the reaction termination condition is that the heating rate is ≥0.05°C / min, start the device to heat, and the sample The cell is heated up to the initial temperature of 20°C and then waits for the temperature to balance. After the temperature is balanced, search for the temperature, heat flow, pressure and sample cell temperature rise rate at the same time, and compare the sample cell temperature rise rate with the reaction termination conditions and reaction judgment sensitivity. When the heating rate of the sample cell is less than 0.05°C / min, that is, the reaction termina...

Embodiment 2

[0048] Add 1g of TATB explosives into the sample cell of the improved micro-calorimeter, evacuate the sample cell, and set the initial temperature to 25°C, the waiting time to 15 minutes, and the constant temperature time to 15 minutes on the control system of the improved micro-calorimeter. , the temperature rise step is 5°C, the reaction judgment sensitivity is -0.02°C / min, and the reaction termination condition is that the temperature rise rate is ≥0.05°C / min, the heating device is started, and the heating and judgment process of the equipment is the same as that of Example 1, only the judgment data Use data from this example. When the temperature rise rate ≥ 0.05°C / min is detected, the instrument test enters the termination stage. In this embodiment, the improved microcalorimeter enters the termination stage when the temperature rise rate just exceeds 0.05°C / min.

[0049] During the heating process of the improved microcalorimeter, the pressure, temperature and heat flow c...

Embodiment 3

[0051] Add 2g of PETN explosives into the sample pool of the improved micro-calorimeter, evacuate the sample pool, and set the initial temperature to 21°C, the waiting time to 10min, and the constant temperature time to 25min on the control system of the improved micro-calorimeter , the temperature rise step is 0.2°C, the reaction judgment sensitivity is -0.02°C / min, and the reaction termination condition is that the temperature rise rate is ≥0.05°C / min. The process of heating and judgment of the equipment is the same as that of Example 1, and only the judgment data is used in this embodiment The data. When the temperature rise rate ≥ 0.05°C / min is detected, the instrument test enters the termination stage. In this embodiment, the improved microcalorimeter enters the termination stage when the temperature rise rate just exceeds 0.05°C / min.

[0052] During the heating process of the improved microcalorimeter, the pressure, temperature and heat flow changes in the sample cell ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com