Formaldehyde gas sensor

A formaldehyde gas and sensor technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of high production cost, high sensor cost, and short service life, and achieve stable detection results, high detection sensitivity, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the content of the present invention is not limited to the following embodiments.

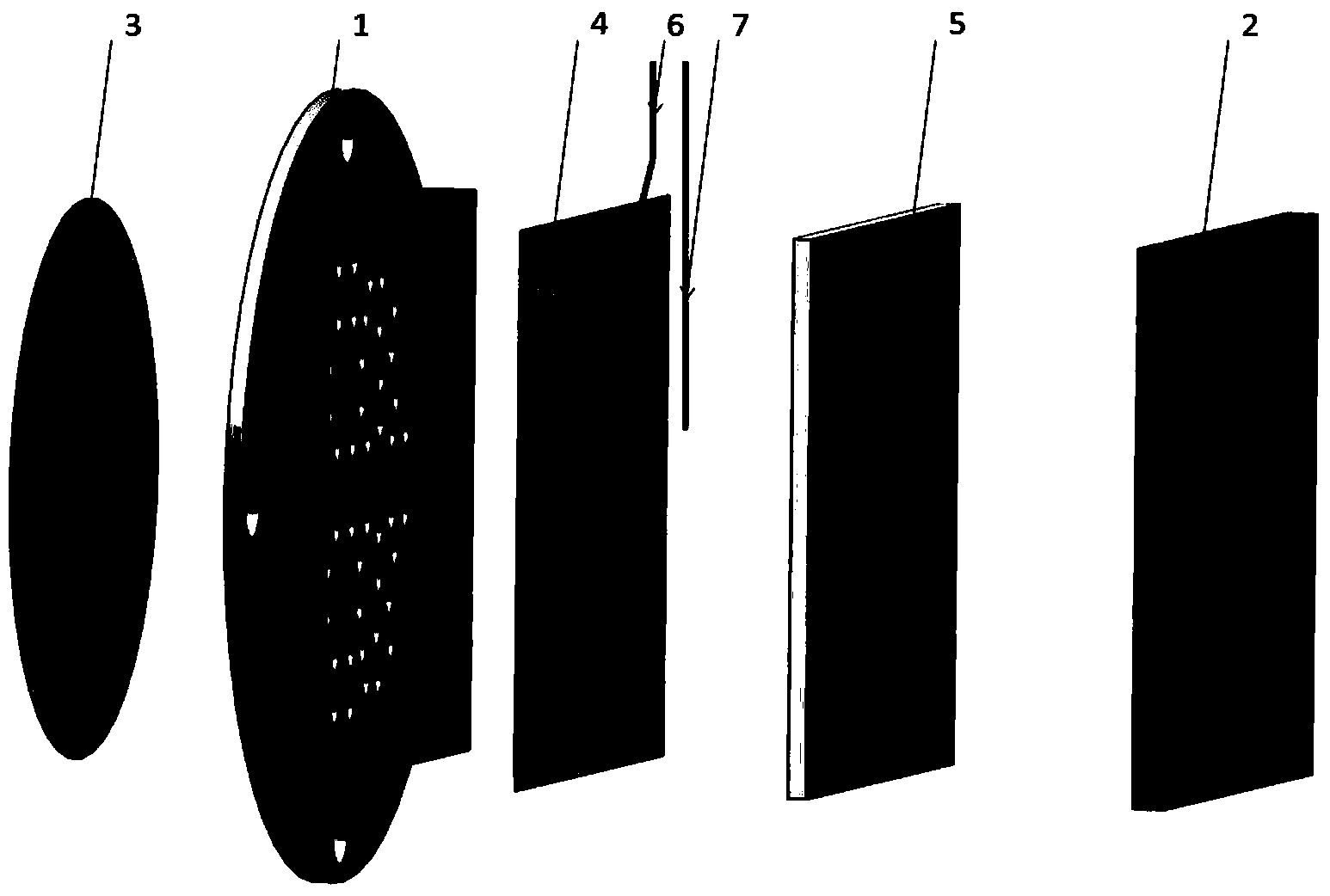

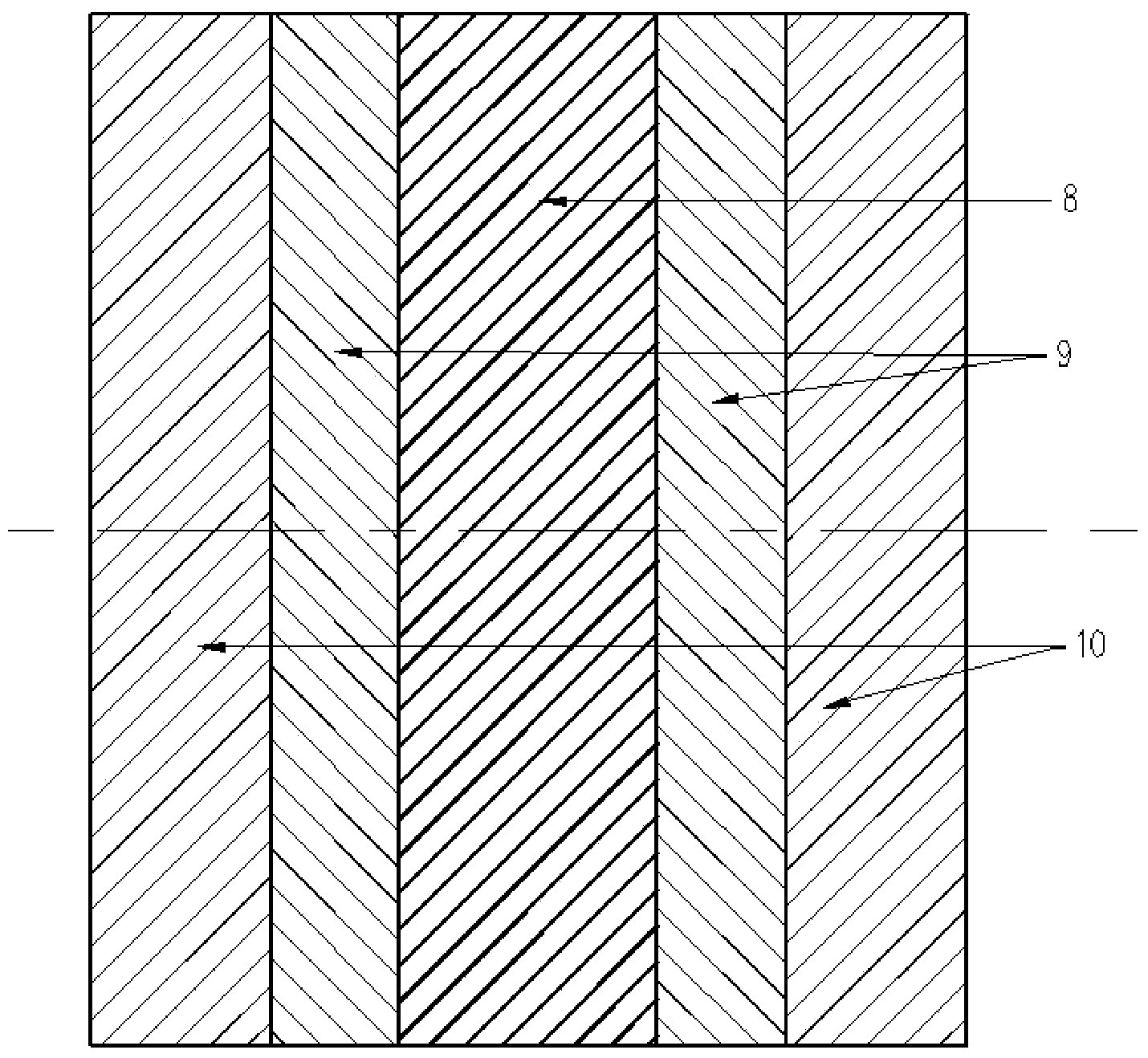

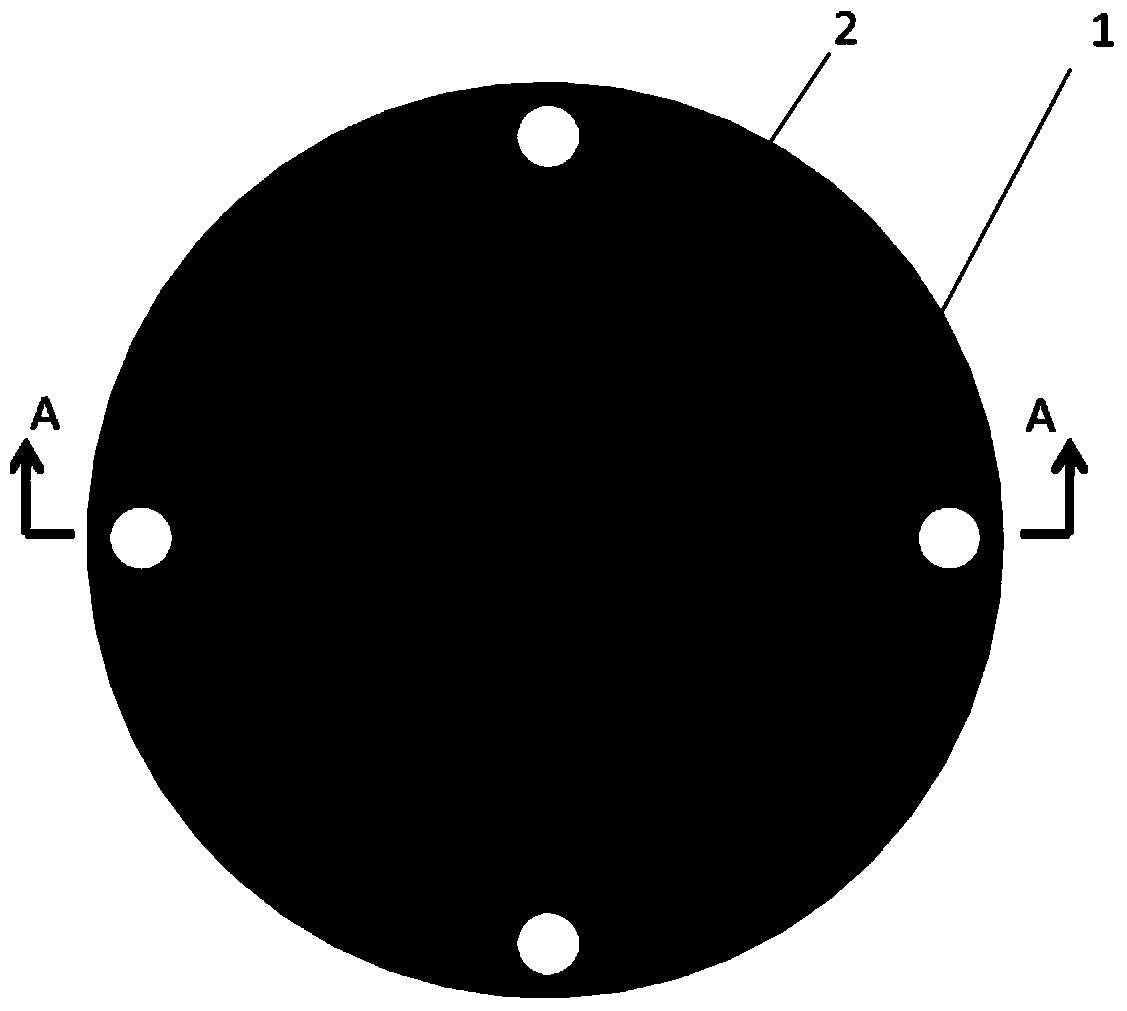

[0024] figure 1 It is the structural representation of formaldehyde gas sensor of the present invention, as figure 1 As shown, the formaldehyde gas sensor provided by the present invention includes: an air inlet filter membrane 3 , an air inlet casing 1 , an anode lead 6 , a membrane electrode assembly 4 , a cathode lead 7 , a cavity support 5 and a sealed casing 2 .

[0025] Among them, the air inlet shell 1 with the air inlet and the sealed shell 2 embedded in it form a hollow closed shell, and the hollow closed shell is from left to right, and the anode lead 6, the membrane electrode assembly 4, and the cathode lead 7 are respectively placed inside. The cavity support body 5 and the air inlet filter membrane 3 are attached outside the air inlet of the air inlet she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com