Preparation method of transformer iron core

A transformer iron core and iron core technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of limiting the performance and service life of transformers, insufficient control of hysteresis loss, and high manufacturing costs, so as to achieve improvement The effect of service life and performance, simple implementation, and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

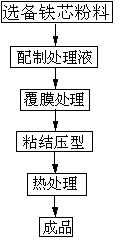

[0018] The specific preparation process of the transformer iron core mentioned in the present invention is as follows:

[0019] a) Select the iron core powder. The iron core blank is made of gas-atomized iron powder, the main component of which is Fe3O4. The average particle size of the iron powder after being ground by a grinder is about 70-75um;

[0020] b) Prepare the treatment solution, the main components of the treatment solution and their percentage ratio are: 10% magnesium oxide, 3% additives, and the rest is solvent; among them, the main components of magnesium oxide are MgO, SiO2 and Fe2O3, Its percentage content ratio is about: 92%: 6.5%: 1.5%; the solvent is prepared by mixing phosphoric acid, boric acid and acetic acid, the mixing ratio is about: 3:3:2, and the concentration after mixing is about 20%; The auxiliary agent includes surfactant and antirust agent, and the surfactant is sodium perfluorooctanoate; the antirust agent is a composite agent of sodium nitrit...

Embodiment 2

[0026] The specific preparation process of the transformer iron core mentioned in the present invention is as follows:

[0027] a) Choose iron core powder, the iron core blank is made of gas-atomized iron powder, the main component is Fe3O4, and the average particle size of the iron powder is about 75-80um after being ground by a grinder;

[0028] b) Prepare the treatment solution, the main components of the treatment solution and their percentage ratios are: 12% magnesium oxide, 3.5% additives, and the rest is solvent; among them, the main components of magnesium oxide are MgO, SiO2 and Fe2O3, Its percentage content ratio is about: 92%: 6.5%: 1.5%; the solvent is prepared by mixing phosphoric acid, boric acid and acetic acid, the mixing ratio is about: 3:3:2, and the concentration after mixing is about 25%; The auxiliary agent includes surfactant and antirust agent, and the surfactant is sodium perfluorooctane sulfonate; the antirust agent is a composite agent of sodium nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com