Highly-integrated electromagnetic bistable-state MEMS relay and manufacturing method of highly-integrated electromagnetic bistable-state MEMS relay

A highly integrated, bistable technology, applied in the direction of electrostatic relays/electro-adhesion relays, relays, circuits, etc., can solve the complex preparation method of three-dimensional solenoid coils, the number of turns of single-chip manufacturing coils, and the high cost of LIGA technology, etc. problem, to achieve the effect of shortening the process cycle, improving overall performance, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

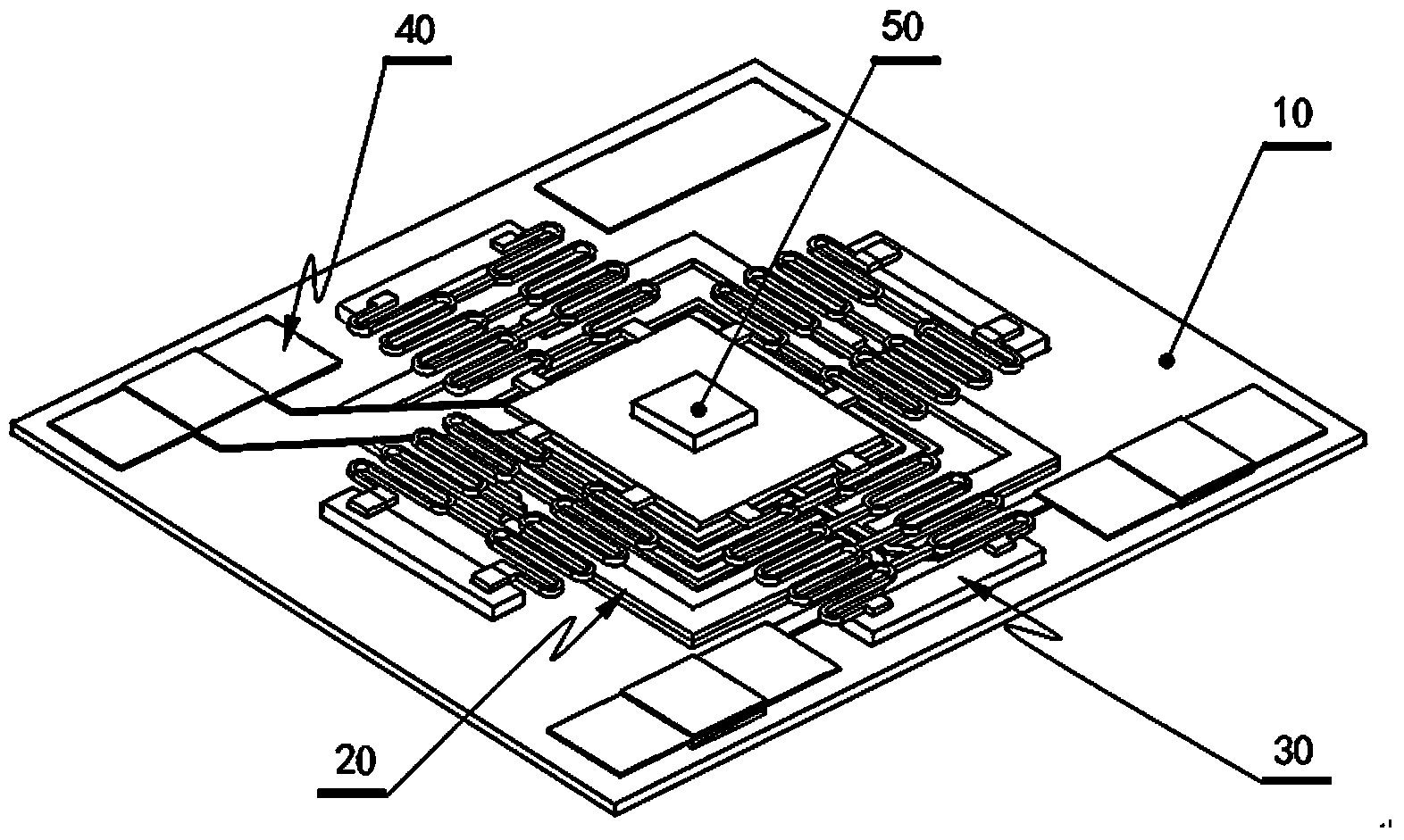

[0044] like figure 1 As shown, a highly integrated electromagnetic bistable MEMS relay provided by the present invention includes: a substrate 10 and an electromagnetic drive system 20 integrated on the substrate 10, an elastic support system 30, a signal switching system 40 and a permanent magnet 50 , the permanent magnet 50 is located above the elastic support system 30 .

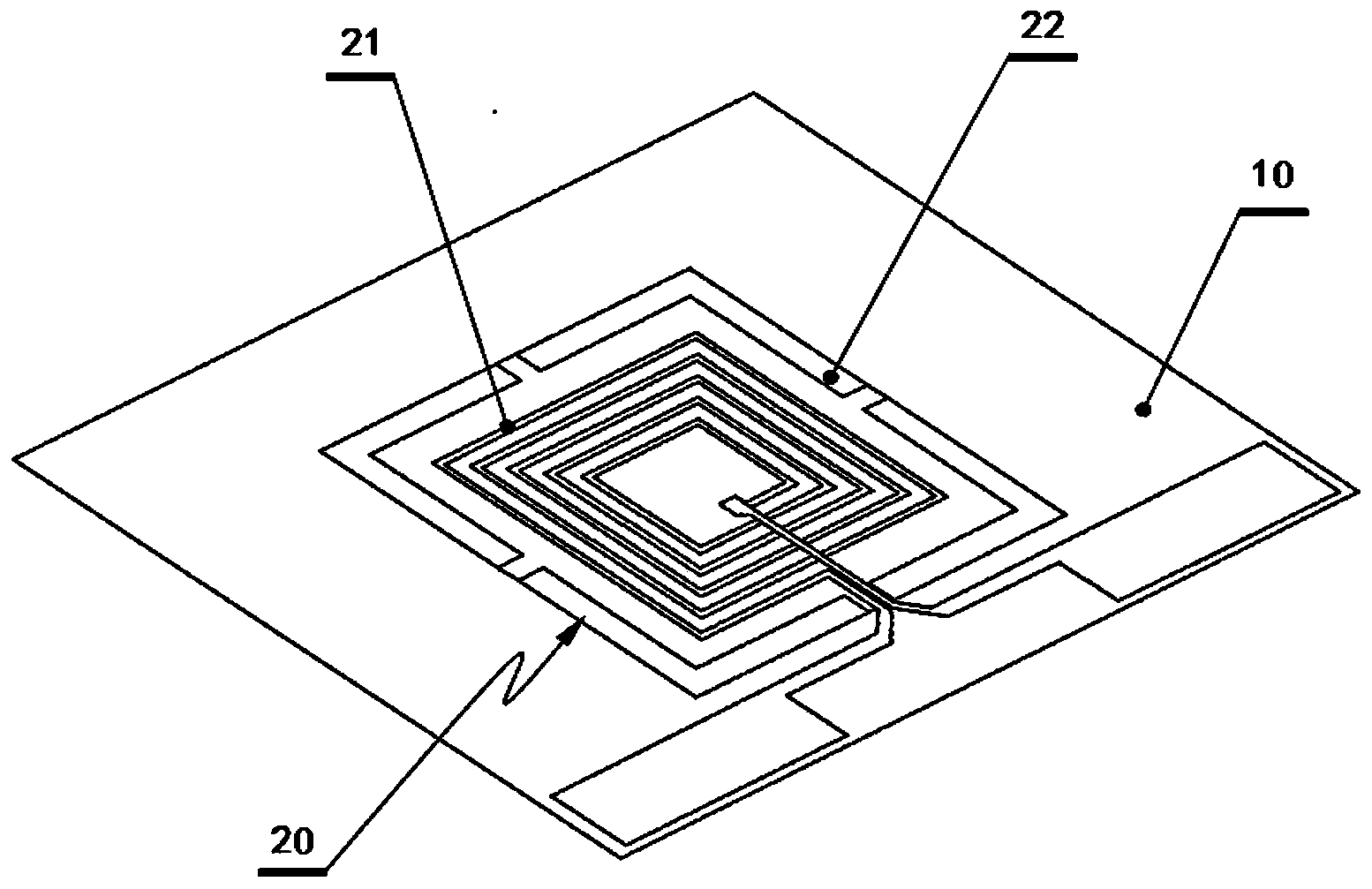

[0045] like figure 2 As shown, the electromagnetic drive system 20 includes a multi-turn spiral planar coil 21 and a closed yoke 22, the closed yoke 22 is distributed in the center, bottom and edge of the planar coil 21; an insulating layer is arranged between the coils; the planar coil The shape of the planar coil 21 can be square, rectangular or circular, and it is square in this embodiment; the planar coil 21 is preferably a single-layer coil, the thickness of the coil is preferably 22-26 μm, and the width is preferably 12-15 μm.

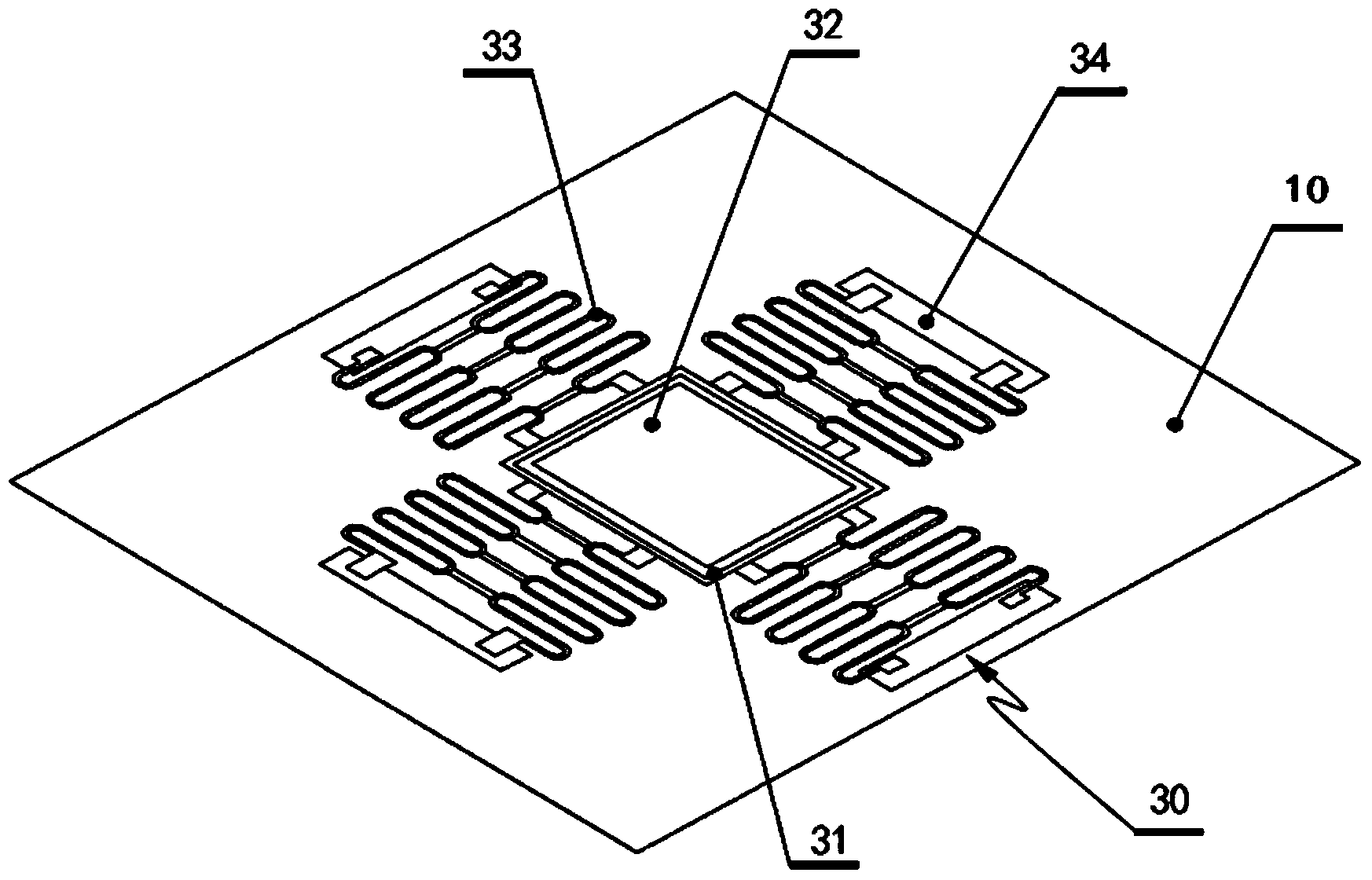

[0046] like image 3 As shown, the elastic support system 30 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com