Fresh cassava noodles and preparing method thereof

A production method and technology of sweet cassava, applied in food preparation, function of food ingredients, food ingredients containing natural extracts, etc., can solve problems such as sales volume limitation, backlog, short cassava harvest period, etc., to delay digestion and absorption, prevent Fat, good effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

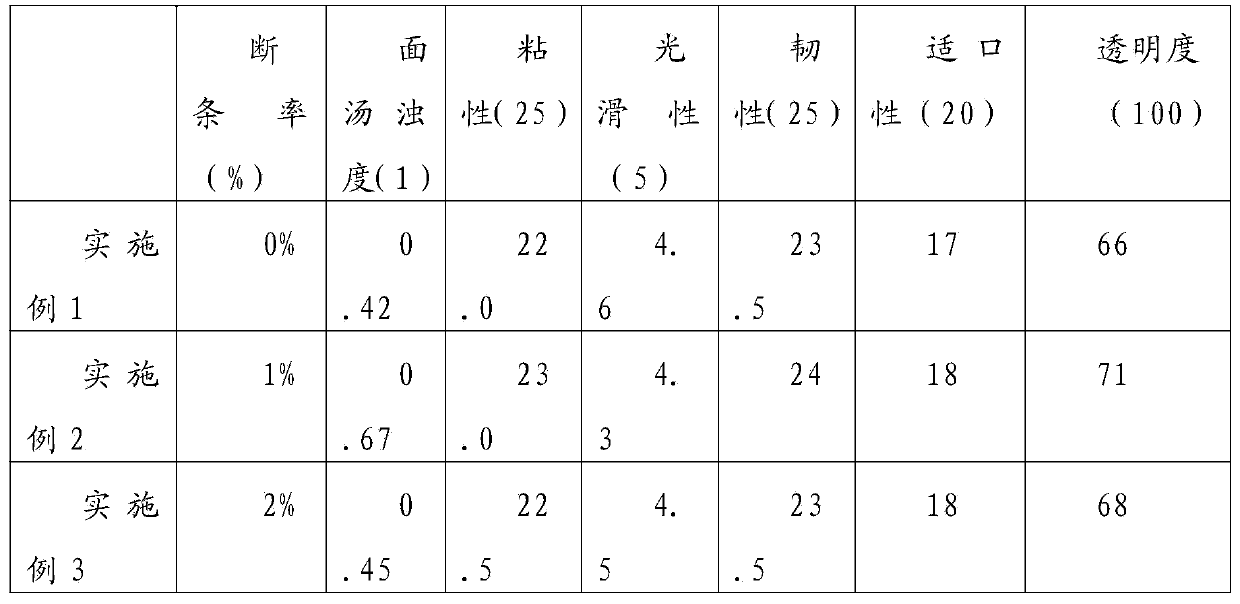

Embodiment 1

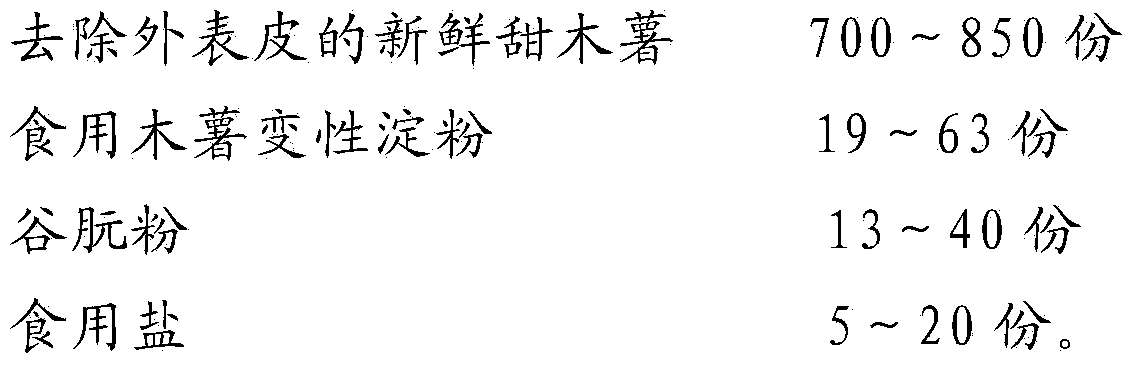

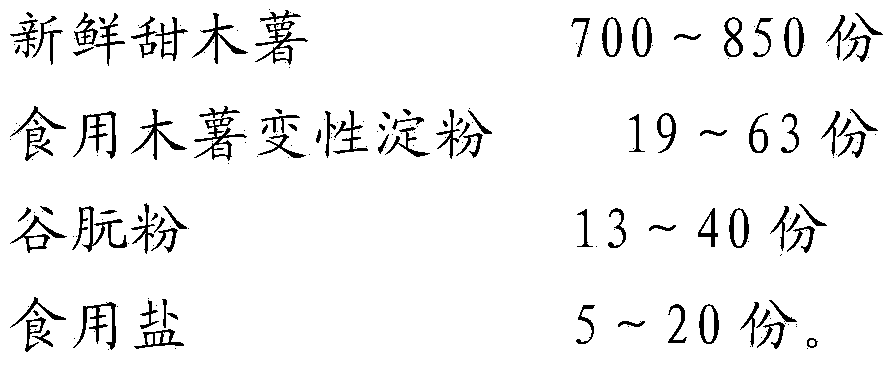

[0023] A kind of fresh sweet cassava noodles, is made up of following components: harvested 700g of SC9 cassava granules for 10 hours, edible starch acetate 63g, gluten 40g, edible salt 20g;

[0024] (1) Pretreatment of SC9 sweet cassava

[0025] ①Take sweet cassava, remove the outer surface thoroughly, and clean;

[0026] ②Using a small vegetable trapping machine to disintegrate the cassava described in ① for 3 times to obtain cassava fine grains with a particle size less than 2.0mm;

[0027] ③ Weigh the fresh cassava grains described in ② in proportion, put them into the sample barrel of the fruit juice machine, start it, set the stirring speed to 32000r / min, and stir for 6 minutes and 40 seconds to obtain fresh cassava pulp.

[0028] (2) take by weighing edible acetate starch, gluten powder, edible salt in proportion, add in the cassava pulp, mix;

[0029] (3) putting the mixture described in (2) into a gluten dehydrator for dehydration, and controlling the water content ...

Embodiment 2

[0033] A fresh sweet cassava noodle consisting of SC9 harvested for 24 hours

[0034] Sweet cassava granules 850g, edible hydroxypropyl starch 19g, gluten 13g, edible salt 5g;

[0035] (1) SC9 sweet cassava pretreatment

[0036] ①Take sweet cassava, remove the outer surface thoroughly, and clean;

[0037] ②Using a small vegetable trapping machine to disintegrate the cassava described in ① 5 times to obtain cassava fine grains with a particle size less than 2.0mm;

[0038] ③ Weigh the cassava grains described in ② in proportion, put them into the sample bucket of the fruit juice machine, start it, set the stirring speed to 32000r / min, and stir for 7 minutes to obtain fresh cassava pulp.

[0039] (2) take described quality edible hydroxypropyl starch, gluten powder in proportion, edible salt, add in the cassava pulp, mix;

[0040] (3) putting the mixture described in (2) into a gluten dehydrator for dehydration, and controlling the water content of the mixture to be 60%;

[...

Embodiment 3

[0044] A kind of fresh sweet cassava noodles, is made up of following components: just harvested sweet cassava granules 780g, edible distarch phosphate 50g, gluten 30g, edible salt 10g;

[0045] (1) Pretreatment of fresh sweet cassava

[0046] ①Take GR891 sweet cassava, remove the outer surface thoroughly, and clean it;

[0047] ②Using a small vegetable trapping machine to disintegrate the cassava described in ① 4 times to obtain cassava fine grains with a particle size less than 2.0mm;

[0048] ③ Weigh the fresh cassava grains described in ② in proportion, put them into the sample bucket of the fruit juice machine, start it, set the stirring speed to 30000r / min, and stir for 7 minutes and 30 seconds to obtain fresh cassava pulp.

[0049] (2) take the edible distarch of phosphate ester of described quality, gluten powder, edible salt, add in the cassava pulp, mix;

[0050] (3) putting the mixture described in (2) into a gluten dehydrator for dehydration, and controlling the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com